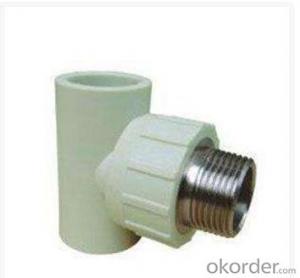

Plastic Water Pipe Fitting - New PPR Tee with Tap Connector Male & Female for Industrial Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Product

1. It is used in industrial fields, agriculture and garden irrigation

2. Beauty appearance.

3. Thermal insulation and energy saving.

4. Easy installation

5. Excellent heat resistance and pressure resistance

PPR Pipe Size

PN10 | PN12.5 | PN16 | PN20 |

20*2.3 | 20*2.8 | 20*3.4 | |

25*2.3 | 25*2.8 | 25*3.5 | 25*4.2 |

32*3.0 | 32*3.6 | 32*4.4 | 32*5.4 |

40*3.7 | 40*4.5 | 40*5.5 | 40*6.7 |

50*4.6 | 50*5.6 | 50*6.9 | 50*8.4 |

63*5.8 | 63*7.1 | 63*8.6 | 63*10.5 |

75*6.9 | 75*8.4 | 75*10.3 | 75*12.5 |

90*8.2 | 90*10.1 | 90*12.3 | 90*15 |

110*10.1 | 110*12.3 | 110*15.1 | 110*18.3 |

Specification

Products name | Brass Ball Valve |

Material | Brass |

Field of Application | Water |

Work temperature | -10℃-110℃ |

Packing | standard export package or customized |

Function | Kitchen, home, commercial, garden and general |

Place of origin | Hebei China(mainland) |

Brand | CMAX |

Certificate | CE,ISO90001 |

Product Advantages:

1. Healthy, bacteriological neutral, conforming to drinking water standards

2. Resistant to high temperatures, good impact strength

3. Convenient and reliable installation, low construction expenses

4. Excellent heat-insulation property from minimum thermal conductivity

5. Lightweight, convenient to transport and handle, good for labor-saving.

6. Smooth inner walls reduce pressure loss and increase flow speed

7. Sound insulation (reduced by 40% compared to galvanized steel pipes)

8. Light colors and excellent design ensure suitability for both exposed and hidden installation

9. Recyclable, environment-friendly, accords with GBM standards

Product Applications

1. Distribution for cool and hot water

2. Duct for drinkable water system

3. Pipes for kinds of high-temperature and low-temperature heating system

4. Pipes for heating and coolling settings in solar energy system

5. Connecting pipe for air conditioners

FAQ

Q1:How Can I Get A Sample?

A1:You can get samples by communicate with our export sales.

Q2:How Long Is Delivery?

A2:Delivery time will be30-45days according to order quantity.

Q3:What Is The MOQ?

A3:MOQ depends on different items.

Q4:What Is Our Normal Payments Terms?

A4:Our normal payment terms now is: T/T, L/C or western union,paypal

- Q: Are plastic pipe fittings suitable for irrigation in greenhouse farming?

- Yes, plastic pipe fittings are suitable for irrigation in greenhouse farming. They are lightweight, easy to install, and resistant to corrosion, making them a cost-effective and durable option for delivering water to greenhouse crops. Additionally, plastic pipe fittings offer flexibility in designing irrigation systems according to specific needs, such as adjustable water flow and distribution.

- Q: Are plastic pipe fittings suitable for potable water supply?

- Yes, plastic pipe fittings can be suitable for potable water supply. They are commonly used in plumbing systems as they are resistant to corrosion, easy to install, and have a long lifespan. However, it is important to ensure that the plastic pipe fittings used are specifically designed and certified for potable water applications to meet safety standards and regulations.

- Q: Are plastic pipe fittings suitable for offshore oil and gas platforms?

- Yes, plastic pipe fittings can be suitable for offshore oil and gas platforms. They offer various advantages such as corrosion resistance, lightweight, and ease of installation. However, the specific suitability depends on factors like the type of plastic used, the operating conditions, and the specific requirements of the platform. It is important to consider the specific application and consult with experts to ensure the right material and fittings are selected for offshore environments.

- Q: Can plastic pipe fittings be used for both hot and cold water supply?

- Yes, plastic pipe fittings can be used for both hot and cold water supply.

- Q: Are plastic pipe fittings suitable for compressed air systems?

- Plastic pipe fittings are generally not suitable for compressed air systems. Compressed air systems require materials that can withstand high pressures and temperature fluctuations, and plastic fittings may not have the necessary strength and durability. Metal fittings, such as those made from brass or stainless steel, are typically recommended for compressed air systems to ensure safety and reliability.

- Q: How do plastic pipe fittings handle high-velocity water flow?

- Plastic pipe fittings are generally designed to handle high-velocity water flow effectively. They are constructed using durable materials such as PVC or CPVC, which have excellent resistance to erosion and corrosion. The smooth interior surface of plastic pipes and fittings helps to reduce frictional losses and turbulences, enabling efficient water flow even at high velocities. Additionally, plastic fittings are often designed with secure and reliable jointing mechanisms, ensuring they can withstand the pressure and forces associated with high-velocity water flow without leaking or failing.

- Q: How do you connect plastic pipe fittings?

- To connect plastic pipe fittings, you typically need to follow these steps: 1. Ensure that the pipe and fittings are clean and free from any debris or dirt. 2. Apply a suitable solvent cement to both the pipe and fitting surfaces. 3. Insert the pipe into the fitting firmly and make sure it is fully seated. 4. Hold the joint in place for a few seconds to allow the cement to bond and set. 5. Wipe away any excess cement and allow the joint to cure as per the manufacturer's instructions.

- Q: Are plastic pipe fittings suitable for desalination plants?

- Yes, plastic pipe fittings are suitable for desalination plants. Plastic fittings are corrosion-resistant, lightweight, and durable, making them ideal for use in desalination plants where there is constant exposure to saltwater. Additionally, plastic fittings are easy to install, maintain, and have a longer lifespan compared to traditional metal fittings.

- Q: Can plastic pipe fittings be used in hydroponic systems?

- Yes, plastic pipe fittings can be used in hydroponic systems. They are commonly used due to their durability, affordability, and resistance to corrosion. Additionally, plastic pipe fittings are lightweight, easy to install, and can handle the water and nutrient solutions used in hydroponics.

- Q: How do you connect plastic pipe fittings to HDPE pipes?

- To connect plastic pipe fittings to HDPE pipes, you can use compression fittings, which consist of a compression nut and a compression ring. These fittings are designed to create a tight seal by compressing the ring onto the pipe when the nut is tightened. This method allows for a secure and leak-proof connection between the plastic pipe fittings and HDPE pipes.

Send your message to us

Plastic Water Pipe Fitting - New PPR Tee with Tap Connector Male & Female for Industrial Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords