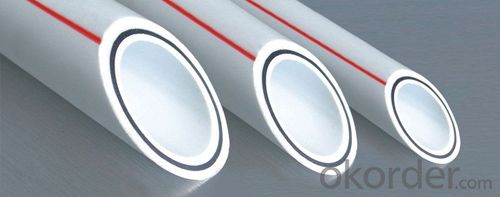

High Quality Plastic Threaded Pipe Fittings for New PPR Household Plastic Pipe Suppliers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

1.It is used in industrial fields, agriculture and garden irrigation

2. Beauty appearance.

3.Thermal insulation and energy saving.

4. Easy installation

5.excellent heat resistance and pressure resistance

6. affordable price

Quick Details:

| 1.Material: | PPR |

| 2Color: | White,Gray,Green,or as your required |

| 3.Size: | 20-110mm |

| 4.Logo: | CMAX or Customized |

| 5.MOQ: | 500pcs |

| 6.OEM Accepted: | Yes |

| 7.Certification available: | Yes |

| 8.Packing Details: | Weaving Bag |

| 9.Production Capacity: | 5,000,000pcs Per month |

Specifications:

1) Material:HYOSUNG R200P, Basell H5416

2) Size:20-160MM

3) Standard:DIN8077/8078

4) Pressure:PN10

PPR Pipes Advantages:

1. Sanitization & Non-poison: This product is green building material which is able to use for pure clean drinking water pipe system. No heavy metal additives would not be covered with dirt or contaminated by bacterium.

2. High Temperature Resistance: the maximum sustained working temperature is up to 70 Degrees Celsius, the maximum transient temperature is up to 95 Degrees Celsius.

3. Corrosion-Proof & Non-Fouling: Resist chemical matters or electron chemical corrosion. Able to avoid the pipe's fouling or blocking as well as the blemish, rust on basin and bath.

4. Heat Preservation & Energy-Saving: Excellent heat insulation features, minimal thermal conductivity which is only 0.5% of the conductivity of metal pipes.

5. Less Weight & High Strength: Its proportion is only 1/8th of metal pipe’s, with pressure-proof strength up to over 5MPa(50kg/sqcm),high tenacity and impact resistance.

FAQ

Q1. Can I have a sample order for valve?

A: Yes, we welcome sample order to test and check quality.Mixed samples are acceptable.

Q2. Do you have any MOQ limit for valve order?

A: Low MOQ, 1pc for sample checking is available

Q3. How do you ship the goods and how long does it take to arrive?

A: We usually ship by sea. It usually takes 30 days to arrive. Airline shipping also optional.

Q4. How to proceed an order for valve?

A: Firstly let us know your requirements or application. Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms the samples and places deposit for formal order.

Fourthly We arrange the production.

- Q: Can plastic pipe fittings be used for stormwater drainage systems?

- Yes, plastic pipe fittings can be used for stormwater drainage systems. Plastic fittings are commonly used in stormwater drainage systems due to their durability, resistance to corrosion, and ease of installation. They are also cost-effective and can withstand the harsh outdoor conditions typically associated with stormwater drainage.

- Q: Can plastic pipe fittings be used for underground drainage systems?

- Yes, plastic pipe fittings can be used for underground drainage systems. They are commonly used due to their durability, resistance to corrosion, and ease of installation. However, it is important to select fittings that are specifically designed for underground use, as they need to withstand the pressure and environmental conditions associated with burial.

- Q: Are plastic pipe fittings suitable for offshore oil and gas platforms?

- Yes, plastic pipe fittings can be suitable for offshore oil and gas platforms. They offer advantages such as corrosion resistance, lightweight construction, and ease of installation. However, the suitability of plastic pipe fittings depends on various factors including the specific application, operating conditions, and industry regulations. In certain cases, more durable and robust materials like stainless steel may be preferred. It is essential to consider the requirements and consult with experts to determine the most appropriate fittings for offshore platforms.

- Q: Are plastic pipe fittings UV resistant?

- Yes, plastic pipe fittings can be UV resistant. Many manufacturers produce UV-resistant plastic pipe fittings that are specifically designed to withstand the damaging effects of ultraviolet (UV) radiation from the sun. These fittings are made from materials that have been formulated to prevent degradation or discoloration when exposed to UV rays, making them suitable for outdoor applications.

- Q: What are the common materials used for plastic pipe fittings?

- Common materials used for plastic pipe fittings include PVC (polyvinyl chloride), CPVC (chlorinated polyvinyl chloride), PEX (cross-linked polyethylene), and ABS (acrylonitrile butadiene styrene).

- Q: Are plastic pipe fittings compatible with solvent welding?

- Yes, plastic pipe fittings are compatible with solvent welding. Solvent welding is a common method used to join plastic pipe fittings together by applying a solvent cement that chemically melts the surfaces of the fittings, creating a strong and durable bond.

- Q: Do plastic pipe fittings require glue or solvent during installation?

- Yes, plastic pipe fittings typically require the use of glue or solvent during installation to ensure a secure and watertight connection.

- Q: Are plastic pipe fittings resistant to heat?

- Yes, plastic pipe fittings are generally resistant to heat. However, the level of heat resistance may vary depending on the type of plastic used in the fittings. It is important to consider the specific temperature and application requirements to ensure the appropriate plastic material is chosen for the intended use.

- Q: Can plastic pipe fittings be used for chemical reactors and tanks?

- No, plastic pipe fittings are not suitable for chemical reactors and tanks as they may not have the necessary resistance to withstand the corrosive nature of chemicals and could lead to leaks or failure.

- Q: Can plastic pipe fittings be used for chemical mixing systems?

- Plastic pipe fittings can be used for chemical mixing systems, but it is important to select fittings made from chemically resistant materials that can withstand the specific chemicals being used.

Send your message to us

High Quality Plastic Threaded Pipe Fittings for New PPR Household Plastic Pipe Suppliers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords