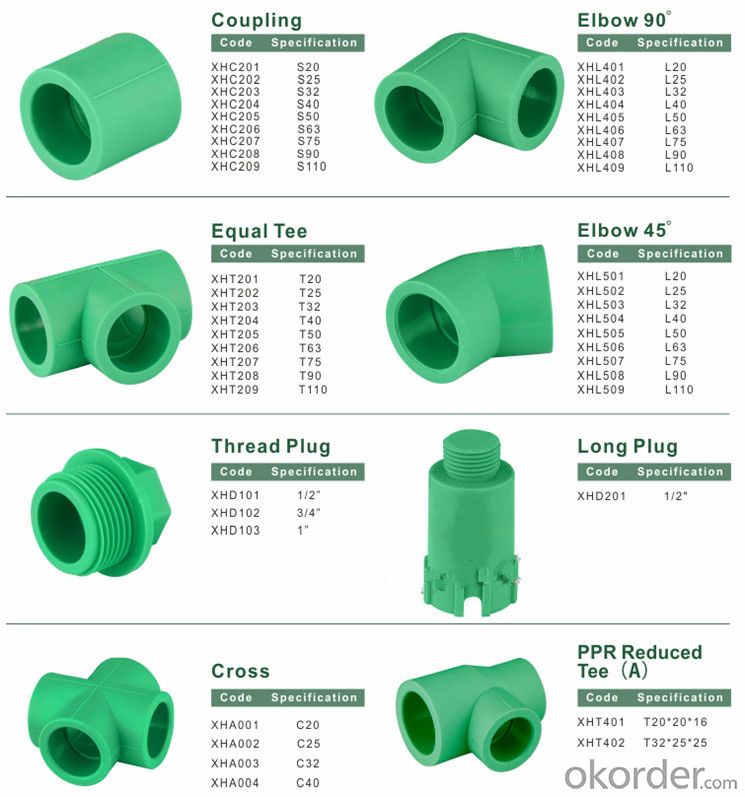

Black Plastic Drain Pipe Fittings - PPR All Plastic Fittings Pipe Plastic Material Elbow 90° L20-110

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of PPR fittings pipe plastic material

1. size: 40-110mm

2. universal or OEM ODM

3.No heavy metal additives

China polypropylene fittings pipe plastic material of PPR fittings pipe plastic material

Recycled and Environmental friendly.

Applications of PPR fittings pipe plastic material:

1) Water supply systems: civil and industrial constructions, in residential buildings, hospitals,hotels,

school and office buildings, ship, building

2) Drinking water systems & food industry pipe works

3) Central air conditioning system

4) Irrigating system for gardens and green houses

5) Public and sport facilities: swimming pools & stadiums

6) Rainwater utilization systems

Features & Advantages of PPR fittings pipe plastic material:

1.Sanitization & Non-poison: It is green building material without heavy metal additives,able to be used for pure clean drinking water pipe system.

2.High Temperature Resistance: the maximum sustained working temperature is up to 70 Degrees Celsius, the maximum transient temperature is up to 95 Degrees Celsius.

3.Corrosion-proof & Non-fouling: Resist chemical matters & electron chemical corrosion, avoiding fouling,blocking, blemish, rust on basin and bath.

4.Beautiful Appearance & Higher Flow Capacity: Smooth inner and outer surfaces, les flowing resistance,

soft color and beautiful figure.

5.Easy and Reliable Installation: Using heat melting joint without sleeve wire, and taking few seconds for connecting and adopting good quality copper inserts to connect the metal pipe and basin.

6.Long Using Life: able to be used for over 50 years under normal condition.

Sizes of PPR fittings pipe plastic material:

Pictures of PPR pipes and fittings

Packing of PPR pipes and fittings:

FAQ:

1. why choose our factory ?

we are the professional ppr maufacuter the products series is very completely .

we have the professnial exported team more exprience ,reasonable price and best sales service . we have office

all overthe world .the customer is spread over the world .the exported market is the southeast ,asica,the

north and south america ,the european and middle east place so on !

2.How to order?

do not hesitate to contact by online or Email as soon as possible once you are interested in our products. The specific quotation will be offered basing the request dimension and quantity.x

3. Can you offer sample pipes and visit my factory?

Yes, we can. But as usual, the buyer have to pay the shipment fee for the sample.

4. What about the quality?

all products according to ISO and National highest standard, also we can offer CE, ASTM certificate if necessary. The guarantee and insurance is 50 years upon rational usage.

5. What payment is available?

Most payment method is available such as L/C, T/T and so on. At usual, 30% t/t deposited before producing and 70% C/L upon B/L for huge purchase.

6.the advantage for us ?

You may be looking for good plastic supplier hard, and you may waste of much time to find similar products at simiar price, and maybe some trading company is wasting your time to chose by higher price .P send your purchase list and you will see how professional we are.

7.Guaranteed:

If products’ quality don’t accord to discription as we give or the promise before you place order,

we promise 100% refund.Our service formula: best quality+best price+best service=customer’s trust

- Q: How do plastic pipe fittings compare to nylon fittings?

- Plastic pipe fittings and nylon fittings have distinct differences. Plastic pipe fittings are typically made of PVC or CPVC and are known for their durability and resistance to chemicals. They are commonly used in plumbing and irrigation systems. On the other hand, nylon fittings are made of a synthetic polymer known for its strength, flexibility, and resistance to impact. They are often used in applications requiring high pressure and temperature. Overall, the choice between plastic pipe fittings and nylon fittings depends on the specific requirements of the project and the compatibility with the intended use.

- Q: PE is the hot melt?

- 1. When using this method, the hot melt butt welding machine is adopted, and the main operation steps are as follows:After the butt welding machine has been debugged, put the pipe to be placed on the welding jig and clamp;The cleaning pipe end to be connected and connected with two end milling cutter alignment docking, the displacement is not greater than the pipe wall thickness of 10%:When the temperature of the heating plate reaches the set temperature, put it on the heating plate:After heating, take out the heating plate, quickly start the oil pump pressure, join the two pipe heating surface, and step up to the welding pressure, keep pressure and cool down:After cooling to the specified time, open the clamp and remove the pipe from the rack, observe the roll edge, determine the quality of the connection, and complete the connection.2. Check the quality of hot melt butt jointThe determination of the quality of hot melt butt welding is still mainly concerned with nondestructive appearance inspection of welding roll edges. Usually includes edge geometry and cutting edge visual inspection, the edge to behind the buckling to prove that connected with no lack of fusion check.Ultrasonic testing and X ray examination have been applied abroad.Destructive detection. Tensile test, bending test and tensile creep test are carried out at the interface respectively.3, hot melt docking notes:The procedures for the use of the docking machines and the matters needing attention shall be observed;Operators must wear gloves, wear overalls, do a good job of self-protection, to avoid electric shocks or burns;Heating the surface of the board, and the connecting ends should be kept clean:Docking pressure should be adjusted to the actual needs of the site:Polyethylene pipes shall not be heated by open flame;The welding interface to protect from sand and rain hit.

- Q: Are plastic pipe fittings resistant to high-temperature chemicals?

- Yes, plastic pipe fittings are generally resistant to high-temperature chemicals. However, the level of resistance may vary depending on the type of plastic used and the specific chemicals involved. It is important to consult the manufacturer's specifications or seek professional advice to ensure the correct plastic pipe fittings are chosen for high-temperature chemical applications.

- Q: How do you choose the right size of plastic pipe fittings?

- To choose the right size of plastic pipe fittings, you need to consider the diameter and material of the pipe you are working with. Measure the outer diameter of the pipe accurately and match it with the corresponding fitting size. Additionally, ensure that the fitting material is compatible with the pipe material to ensure a secure and leak-free connection.

- Q: Can plastic pipe fittings be used in fire detection systems?

- No, plastic pipe fittings cannot be used in fire detection systems as they do not meet the necessary fire safety standards and are not designed to withstand high temperatures. Metal fittings are required to ensure the integrity and reliability of the system in case of a fire.

- Q: Are plastic pipe fittings durable?

- Yes, plastic pipe fittings are generally durable and long-lasting. They are resistant to corrosion, chemicals, and UV radiation, making them suitable for a wide range of applications. However, the durability of plastic pipe fittings can vary depending on the type of plastic used and the specific conditions they are exposed to.

- Q: Are plastic pipe fittings resistant to fire?

- Plastic pipe fittings have varying degrees of fire resistance, depending on the type of plastic used. PVC (polyvinyl chloride) fittings, for example, have low resistance to fire and can melt or burn when exposed to high temperatures. On the other hand, CPVC (chlorinated polyvinyl chloride) fittings are specifically designed to be more flame-resistant and can withstand higher temperatures without melting or burning. It is essential to choose the appropriate plastic pipe fitting based on the specific fire safety requirements of the installation.

- Q: Do plastic pipe fittings require regular maintenance?

- Plastic pipe fittings generally do not require regular maintenance. However, it is important to periodically inspect them for signs of wear, leaks, or damage. Regular maintenance might include checking for loose connections, replacing damaged fittings, and ensuring proper alignment.

- Q: Can plastic pipe fittings be used for chemical mixing systems?

- Plastic pipe fittings can be used for chemical mixing systems, but it is important to select fittings made from chemically resistant materials that can withstand the specific chemicals being used.

- Q: Can plastic pipe fittings be used in fire hydrant systems?

- No, plastic pipe fittings are not suitable for use in fire hydrant systems due to their inability to withstand high pressure and heat.

Send your message to us

Black Plastic Drain Pipe Fittings - PPR All Plastic Fittings Pipe Plastic Material Elbow 90° L20-110

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords