Mirror Series Aluminium Composite Panel Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

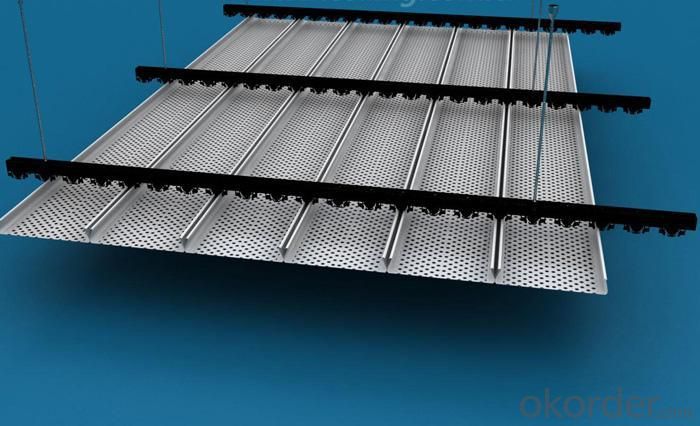

Adopt high-quality aluminum alloy real materials with standard mould, make the ceiling tile install soomth and easy.

Adopt high quality and ECO-Friendly surface treatment technologies, such as wooden/stone color coated, spray painted, etc., make the ceiling tile beautiful and matching to various spaces.

Product Applications:

♦ Supermarkets, Shopping malls, Shops.

♦ Outdoor facilities, Gas station, Toll station.

♦ Subway Station, Railway Station, Bus station, Airport.

♦ Schools, Offices, Meeting rooms, bookstores. Stadiums.

♦ Building lobby, Corridors, Toilets.

♦ Supermarkets, Shopping malls, Shops.

♦ Outdoor facilities, Gas station, Toll station..

Product Advantages:

1.Durability:

Good materials and sophisticated fabrication technology ensure durability of ceilings throughout their lifespan;

2.Environmental:

Aluminum ceiling does not contain harmful substance to environment. The aluminum alloy is recyclable and reused;

3.Sound absorbing:

Sound absorption function will be increased vastly by perforated holes and non-woven fabric, which is anti-inflammable;

Main Product Features:

(1)Clip-in aluminum ceiling is made from high quality aluminum panels (0.6mm-1.2mm thick).

(2) International standard 1100H24, 3003H24, or 5005H24 aluminum alloy depending on requirements; galvanized iron and stainless steel are made available as well.

(3)Clip-in aluminum ceiling is made from high quality aluminum panels (0.6mm-1.2mm thick).

(4) International standard 1100H24, 3003H24, or 5005H24 aluminum alloy depending on requirements

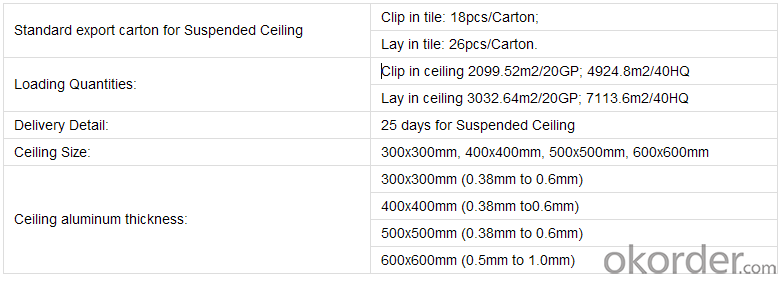

Product Specifications:

FAQ:

Q1: Is your company a manufacturer or a trading company?

A: We are a professional metal building material manufacturer with the advantage of direct and consistant quality control, more competitive pricing and smooth services. We welcome to visit our company and manufacturing site located in Shanghai, China and hope that we can foster a long-term business relationship with you.

Q2: What if I cannot find a desired model in your catalogue or online product displays?

A: With 20 years of experience in landscape projects, we are experienced and expertised to make customized products according to different designing needs. The catalogue only includes part of our standard models. Just tell us what you want to achieve or give us your drawings, and we will find a solution for you.

Q3: What is your accepted payment terms?

A: We prefer T/T,Westunion,and Paypal. We are open to the negotiation about payment terms with our clients before signing up the contract.

Images:

- Q: Can aluminum plate prevent radiation?

- Depends on the installation method, not directly put aluminum, aluminum can also be a role in the ground. Grounding is to connect the aluminum plate with the earth, so that the electromagnetic waves on the aluminum plate will be absorbed into the power of aluminum and flow to the ground, if not ground will produce the other side of the aluminum field, is tantamount to go through. In fact, grounding is very simple, if the installation of metal screws directly with the aluminum contact, but also with the cement wall contact can be considered ground, although not a good grounding. If the wall is wood or the like insulation material can not, then there is a screw, if it is the kind of hole in the wall into the plastic sleeve is not enough, because the plastic insulation.

- Q: By the radiator, affixed to the wall of the aluminum-plastic plate afraid of high temperature by radiator, affixed to the wall of the aluminum-plastic plate afraid of high temperature

- Hello, aluminum-plastic plate with high temperature, corrosion-resistant advantages, but a long time baking, will be relatively reduced service life. Hope can help you.

- Q: When are the sets of layers? Which item is to be set?

- Aluminum-plastic plate, also known as aluminum-plastic composite panels, is a composite aluminum plate and plastic plate.

- Q: The so-called male fear of the wrong line, the recent interview with the two companies, do not know which line is appropriate, very tangled. Do the aluminum veneer boss said that the fire shutter doors have been done rotten, do not know is not true? Knowledgeable brother to help talk about.

- Things are not easy, the key in the heart. OKorder OKorder

- Q: Will the aluminum plate can make a wardrobe?

- Aluminum-plastic composite board is a chemically treated coated aluminum sheet for the surface material, with polyethylene plastic as the core material, in the special aluminum-plastic plate production equipment from the processing of composite materials. The unique performance of the aluminum-plastic composite panel itself determines its wide range of uses: it can be used for building facades, curtain wall panels, retrofits of old buildings, interior walls and ceilings, advertising signs, display stands, engineering. Belonging to a new type of building decoration materials.

- Q: Does the production process produce toxic substances? What is the impact on the body? Does the production of coated aluminum also produce toxic substances?

- Dust hazards Aluminum plants in the production process of dust mainly aluminum oxide dust, petroleum coke dust, asphalt dust. Alumina dust mainly exists in the electrolytic plant, the alumina storage and transportation system; the calcining section of the feeding system, nesting system, calcined after the section of the kneading machine, preheating screw machine and milling system dust and asphalt smoke; There are asphalt smoke generated; residual processing section of the coarse crushing, ingredients, screening and other processes are dust generated. Crane driver, electrolysis workshop workers, carbon powder broken, screening and other workers by the dust hazard. According to TJ36-79 "industrial enterprise design health standards" provides that the workshop the maximum allowable concentration of harmful substances in the air, the dust in the production of alumina dust should not exceed 6mg / m3; other dust (when the free silica content of 10% ) Shall not exceed 10mg / m3.

- Q: What is good for plastic and plastic?

- If it is refers to the table tennis racket, no cooked gum this kind of thing ............ raw rubber refers to the particles up, the diameter is greater than the height of the rubber. Its characteristics are hit the ball sink, rubbing the ball is weak. , So it is particularly easy to control the ball. At present a group of horizontal beat two sides attack players, in order to find the ball changes, using the forehand anti-plastic (pull arc) and backhand rubber (fast dial and short) with the method. Today's world champion Wang Tao and the famous players Chen Jing, Geng Lijuan and so on the use of backhand plastic play, rubber can be used as a straight shot against the negative paste a choice.

- Q: Why aluminum-plastic composite board in the cutting of the inner aluminum and polyethylene plastic, should retain not less than 0.3mm thick polyethylene plastic?

- But also to ensure that the corner part of a certain strength and toughness,

- Q: The minimum thickness of single-layer aluminum and aluminum-plastic composite panels for curtain walls

- B. External wall decoration and advertising with aluminum plate on the aluminum plate thickness of not less than 0.20mm rust aluminum, the total thickness should be not less than 4mm. Coatings are generally fluorocarbon coated or polyester coated.

- Q: Chengdu Deyang made of external walls of aluminum-plastic package material how much money a square

- And then account for the local artificial as 80-120 yuan / day, and accessories accessories per square meter at least add 30-80 yuan. This will be the external wall of aluminum plastic package package materials, the full cost.

Send your message to us

Mirror Series Aluminium Composite Panel Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords