Microporous Insulation Board Available in a 7mm, 12.5mm and 25mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Microporous Insulation Board

CMAX Microporous Insulation Board is specially designed for steel industry & metallurgy with very good thermal and mechanical properties. The formulation is an opacified blend of filament reinforced pyrogenic silica. The coverings is water repellent to assure the stability of the microporous board when moisture may occur due to castables, mortar etc.

Features of Microporous Insulation Board

Extremely low thermal conductivity

High compressive strength

High thermal stability

Environment protection

Easy to handle

No harmful inhalable fibers

Resist most chemical attacks

Free of organic binders

Non combustible

Application of Microporous Insulation Board

Ladle

Torpedo Ladle

EAF

Degassers

Cement Rotary Kiln

Ceramic Firing Kiln

Aluminum Melting and Holding Furnace and so on

Working & Processing of Microporous Insulation Board

CMAX Microporous Insulation Board can be shaped easily with a simple cutter and taped off with aluminum tape. The microporous insulation board can be fixed in place with the same adhesives that are used for refractory lining.

Image of Microporous Insulation Board

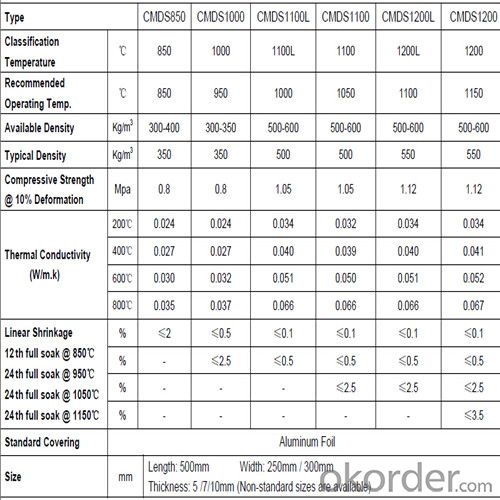

Technical Data of Microporous Insulation Board

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: What kind of insulation material can withstand 350-600 degrees of high temperature?

- GB 50264-97 code for design of thermal insulation engineering for industrial equipment and pipelines98T901 cold storage Atlas of piping and equipment

- Q: What is the maximum temperature at which the glass is cured?

- There is no definite melting point. Ordinary glass is a substance which is made up of soda ash, calcium silicate and silicon dioxide, and Shi Yinghe feldspar is the main raw material.

- Q: What is the difference between calcium silicate board and cement fiber board?

- How to distinguish fiber cement, pressure plate and calcium silicate board?1, calculate density: calcium silicate board density is much lower than the fiber cement pressure plate, through the weight of the plate can calculate its approximate density.2, look at the color: Although there are manufacturers in order to pretend to be fiber cement pressure plate and deliberately add carbon black and so on, the board made dark, but not natural cement color.3, ask whether there are super thin plate and super thick plate, if not or can not do, it means that he is selling calcium silicate board or ordinary fiber cement, non pressure plate.4, if you go to the factory, you can visit its workshop, if there is steam pressure (commonly known as bullets), it is certainly calcium silicate board manufacturers, if there is no press, it is a common cement plant.

- Q: Asbestos free calcium silicate board there is a crack in the kettle, what is the reason?

- Calcium silicate slab blank (blank off off phenomenon is not forming tube adhesion fingerboard blank above)There are two reasons: one is the blank off the vacuum negative pressure is too large, the blank water is too low, low viscosity; two is felt blocked, the billet made worse.The solution is to reduce the negative pressure, strengthen the cloth washing.

- Q: The ceiling of calcium silicate board and mineral wool board which is good

- The fire performance of third mineral wool board no calcium silicate board,Fourth mineral dampeasily yellow, moisture absorption is not good.The calcium silicate board will not have the above shortcomings, the thickness of 15mm if it is the calcium silicate board 4mm ceiling 600*600 thickness can reach the effect of the biggest advantages of mineral wool board, calcium silicate board also is not a burning fire, moisture absorption is very good, green building materials.

- Q: Calcium silicate board white ICI belongs to wood surface paint?

- ICI can generally be considered as wall paint (latex paint), and latex paint can be used on this kind of cement board. And lumber is different, it is not suitable to brush latex paint on the surface of wood, it can only be decorated with paint (oil paint).

- Q: Why is calcium silicate board unsuitable for use in home improvement?

- Because the silica plate contains quartz composition, and the content is still higher. Quartz is a carcinogenic substance, the long-term impact of this substance, the human carcinogenic probability will be greatly enhanced

- Q: What's the use of low carbon steel insulated nail hooks for power plants?

- Mild steel is a type of carbon steel, and its carbon content is between 0.1% and 0.3%. The so-called carbon steel is also called carbon steel, refers to the carbon content of less than 2.11% of the iron carbon alloy. As we all know, the carbon content of the impact on the iron and carbon alloy is very large, the higher the content, the greater the hardness, but the smaller the toughness, and therefore easy to damage. Low carbon steel, because of its low carbon content, therefore, good toughness, low hardness, easy to carry out a variety of processing, such as welding, forging, etc.. And after some heat treatment, low carbon steel can obtain various properties, such as wear resistance, corrosion resistance and so on.

- Q: What's the difference between white cement and ordinary cement?

- White portland cement as the raw meal with the proper components till the partial melting of the calcium silicate as the main ingredient, the iron content in clinker less addition of gypsum, white water ground made of rigid cementitious material. When grinding cement, allow limestone not to exceed 5% of the cement weight. White cement is mostly ornamental, and its manufacturing process is much better than ordinary cement. The gap is mainly used to hook white tiles, is generally not used in the wall, the reason is not high strength. It is available in the building materials market or decoration materials shop.

- Q: What is a building energy-saving materials?

- Heat insulation materials and insulation materials collectively referred to as thermal insulation materials.The commonly used thermal insulation material: mineral wool, rock wool, glass wool (in rock, slag as the main raw material, by high temperature melting, made by centrifugal methods such as cotton and thermosetting resin binder insulation products. ) foam plastics and porous polymers, expanded perlite and their products, calcium silicate insulation products, all kinds of composite insulation materials.

Send your message to us

Microporous Insulation Board Available in a 7mm, 12.5mm and 25mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords