Microporous Insulation Board 0.035W/m.k Lower Conductivity

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1200 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

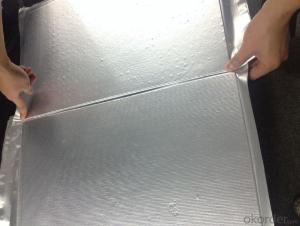

Low Conductivity Microporous Insulation Board (0.035W/m.k)

Product Description:

CMDS Microporous Insulation Board is a microporous technology product, and is made up of a specific blend of filament reinforced fumed silica, which provides superb thermal performance.

It is an ideal back & shy insulation for various industries where high temperatures are needed, or extended exposure to 1150°C.

STD can be shaped both manually and with stationary wood processing machinery. They can be cut, sawn, drilled and punched. The boards can be fixed in place with glue or by mechanical means such as anchors, pins and clips.

Main Product Features:

· Extremely low thermal conductivity

· High thermal stability

· High thermal stability

· Environment protection

· Easy to handle

· No harmful inhalable fibers

· Resist most chemical attacks

Products Images

Products Specifications:

Minimum Order Quantity: | 1200 pc | Unit: | pc | Loading Port: | Shanghai |

Supply Ability: | 20000 pc/month | Payment Terms: | TT or LC | Package: | Pallet |

Product Applications:

Industrial furnaces, fuel cells (SOFC), thermal batteries, Aluminum industry (smelters), glass & ceramics industry, petrochemical industry (cracking furnace, reformer)

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What about payment term?

A4: We accept 30% T/T in advance, with the balance before shipment. L/C at sight is alsoacceptable. Other payment term can be discussed with specific orders.

- Q: What kind of insulation material can withstand 350-600 degrees of high temperature?

- GB 50264-97 code for design of thermal insulation engineering for industrial equipment and pipelines98T901 cold storage Atlas of piping and equipment

- Q: What is the maximum temperature at which the glass is cured?

- The softening point of quartz glass is 1600 degrees, it is sodium phosphate and phosphate. Gas burner 1300 degrees, after homogenization processing, after annealing treatment of glass products.

- Q: What are the high temperature resistant insulation materials at 400?

- According to the general rules of equipment and piping insulation, heat insulation material is a material with a thermal conductivity of less than 0.14W/ (m*K) when the average temperature is equal to or less than 623K (350 degrees Celsius). Heat insulation material is usually light, porous, porous, small thermal conductivity characteristics. Generally used to prevent heat loss of equipment and pipes, or frozen (also known as general cold) and low temperature (also known as cryogenic) use, so in our country, insulation materials, also known as insulation or cold preservation materials. At the same time, because of the porous and fibrous structure of thermal insulation material, it has good sound absorption function, so it is also widely used in the construction industry.

- Q: The ceiling of calcium silicate board and mineral wool board which is good

- Calcium silicate board with fire prevention, moistureproof, sound insulation, thermal insulation, indoor air in wet conditions can attract water molecules in air, air drying, and the release of water molecules, can adjust the indoor humidity, dry, increase comfort.Natural gypsum products and special fireproof material, the flame can produce endothermic reaction, at the same time, the release of water molecules to prevent the fire from spreading, and does not produce any toxic decomposition, corrosive and choking gas, will not produce any smoke or combustibles.Mineral wool board is mineral fiber cotton as raw material, the biggest characteristic is to have good sound absorption and heat insulation effect.

- Q: Cement is not silicate products

- So, we usually call cement as cementitious material - cement products

- Q: What are the new energy-saving building materials? What's new?

- Heat insulation materials and insulation materials collectively referred to as thermal insulation materials.The commonly used thermal insulation material: mineral wool, rock wool, glass wool (in rock, slag as the main raw material, by high temperature melting, made by centrifugal methods such as cotton and thermosetting resin binder insulation products. ) foam plastics and porous polymers, expanded perlite and their products, calcium silicate insulation products, all kinds of composite insulation materials.Application of thermal insulation materials:(1) it is mainly used for thermal insulation of buildings, walls and roofs;(2) thermal insulation of thermal equipment and thermal pipe;(3) a large number of refrigerators and freezers are also used.

- Q: What are the raw materials of cement products? What's the function?

- Cement has a great influence on the properties of concrete. The kinds and quantities of cement containing minerals and the fineness of cement will affect the quality of cement products. The calcium silicate three in cement is an important factor in the coagulation of cement products. The reaction between three calcium silicate and water leads to the production of hydrated calcium silicate, and the hydrated calcium silicate gel acts as a cementing agent for aggregate and aggregate in concrete.

- Q: What is the best price for the use of calcium silicate ceiling?

- Water will melt or become yellow, mildew. So if you choose their ceiling, you must first deal with the roof leak. Calcium silicate board with artificial and material prices of about 22 square meters, mainly for office space, and residential corridors and other public places decoration. Integrated ceiling is not afraid of water.

- Q: What is dew point of thermal insulation material?

- Thermal insulation materials are generally used to guide heat coefficient less than or equal to 0.2 of the material. Thermal insulation material development is very fast, and in industry and building the use of good insulation technology and materials, often can get twice the result with half the effort. Each ton of mineral cotton insulation used in the building saves one ton of oil a year.

- Q: What is a building energy-saving materials?

- As far as its varieties are concerned, the new wall materials mainly include bricks, blocks and slabs, such as clay hollow bricks, waste clay bricks, non clay bricks, building blocks, aerated concrete, light plates and composite boards.

Send your message to us

Microporous Insulation Board 0.035W/m.k Lower Conductivity

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1200 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords