Micropore Insulation Board 1.Fire-retardant 2.Thermal-insulated

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Microporous Insulation Board:

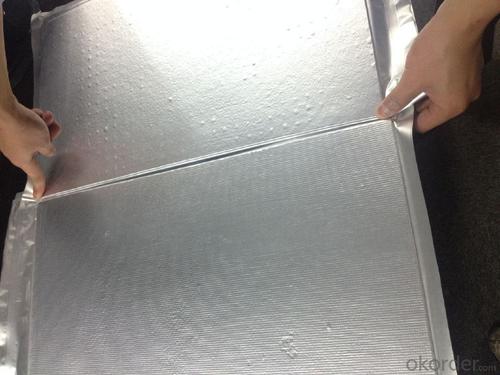

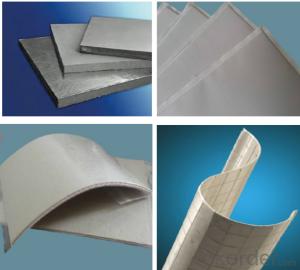

CMDS Microporous Insulation Board is specially designed for steel industry & metallurgy with very good thermal and mechanical properties. The formulation is an opacified blend of filament reinforced pyrogenic silica. The coverings is water repellent to assure the stability of the microporous board when moisture may occur due to castables, mortar etc.

2.Main features of Microporous Insulation Board:

◆ Extremely low thermal conductivity ◆High compressive strength

◆ High thermal stability ◆Environment protection

◆ Easy to handle ◆No harmful inhalable fibers

◆ Resist most chemical attacks ◆Free of organic binders

◆ Non combustible

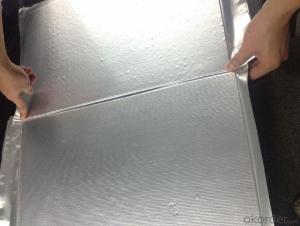

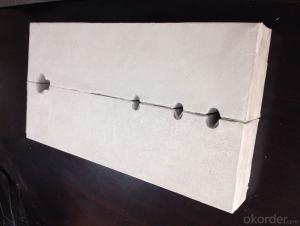

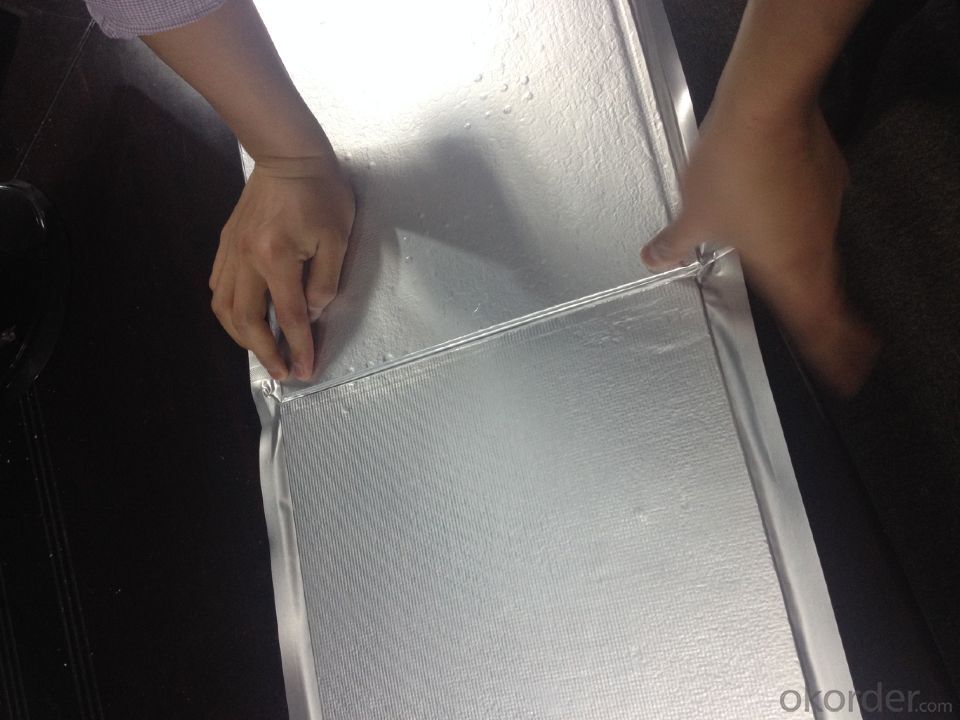

3. Microporous Insulation Board Images:

4. Microporous Insulation Board Technical Parameters

CMDS Microporous Insulation Board can be shaped easily with a simple cutter and taped off with aluminum tape. The board can be fixed in place with the same adhensives that are used for refractory lining.

Application: Ladle, Torpedo Ladle, EAF, Degassers, Cement Rotary Kiln, Ceramic Firing Klin, Aluminum Melting and Holding Furnace and so on. If you need other application picture, please contact with us

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of Microporous Insulation Board is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Slope roof drains do not need to be waterproof

- The overall rigid waterproof layer is often due to these small structural nodes handled properly, resulting in the failure of the entire roof waterproof.

- Q: What is PE waterproof cloth and PVC tarpaulin

- The characteristics and performance index of waterproof cloth products 1. Tensile strength index: warp strength ≥ 2100N / 5CM, zonal strength ≥ 1600N / 5CM; 2. No leakage of water, water pressure ≥ 2000MM water column; 3. Low temperature, cold temperature -20 ℃; 4 Can be mildew, mildew experiment for the first level. Product Usage 1. Can be used car, train, ship cargo tarpaulin; 2. It can be used for the open storage of the harbor airport at the station terminal harbor; 3. Can be set up temporary granary and a variety of crops covered with open-air; 4. Can be used for construction site power construction site and other sites to build temporary shed, temporary warehouse materials; 5. Can be processed camping with tents and various machinery and equipment outside the jacket.

- Q: What decoration materials, light and water, and the wall, the perfect combination of glass

- Between the glass and the wall is generally waterproof with waterproof glue, the specific steps are as follows: First, clean the surface Remove the surface of the joints of water, grease, dust and other pollutants, with a clean cloth to clean all the residue, so that the surface clean and dry. (If it is waterproof glue, the surface should be flat and clean, plastic gap to slightly curved as well.)

- Q: Find the construction steps for waterproof coatings

- 1, base surface treatment (1) roof structure After the completion of concrete pouring, should be repeated water compaction, so that the surface of the grass-roots level, the flatness with 2m to check the ruler, ruler and grass-roots gap of not more than 5 mm, and only allow gentle changes. (2) the base surface of the pores, rugged, honeycomb, gap, sand, etc., should be promptly treated, the base surface must be clean, no floating slurry, no water beads, no water; when the base surface appears more than 0.3 mm cracks , Should rush each 10 cm brushing 1 mm thick polyurethane coating waterproof layer, and then set the polyurethane cloth reinforcement layer, and finally brushing waterproof layer. (3) all the corners are used 5 × 5㎝ 1: 2.5 cement mortar for chamfering, the angle made R = 10 mm rounded corners.

- Q: Hello, roof with SBS waterproof material bulk density is how much?

- SBS Styrene-based thermoplastic elastomer is the largest yield (more than 70%) of SBCs, the lowest cost and wider application. It is a triblock copolymer with styrene and butadiene as monomer. Plastic and rubber properties, known as the "third generation of synthetic rubber".

- Q: Js waterproof coating without powder can brushing

- 4. Coating protection: JS waterproof coating after the end of the construction, not thoroughly dry before the need to protect the coating, including the suppression of pedestrians, rain erosion, exposure, sharp damage to objects; thoroughly dry solid JS cement Emulsion coating does not need to do other protective layer;

- Q: Self-built concrete house finished three years after the use of large-scale housing wall leakage how to do?

- Need to waterproof the external walls, there are several programs. First, directly in the existing external walls of the main surface of the water treatment, the use of technology and materials due to different external finishes and different;

- Q: Roof leakage, what materials do the best waterproof

- hird, for some of the city building cover the construction of red tiles leakage, as long as the removal of tiles on the grass, moss or dust after the replacement of tiles, leak-proof effect is the same. For flat roofs, the roof of the obvious cracks, with the tool will be cracked into a "V" or "U" shape, filling the caulking ointment, filled with cracks and above the use of waterproof wrap around the package. To strengthen the leak-proof effect, you can also shop a layer of waterproofing membrane. Note: Before the waterproofing and draining construction, the roof must be dry, because the roof of the water does not evaporate, the new waterproof layer will rise, the waterproof effect immediately invalid.

- Q: What should you pay attention to before the construction of the basement waterproofing membrane?

- 3, painting the bottom line: for the reasonable arrangement of the daily pavement workload, must first on the basis of the program according to set the program to draw a good dividing line, the entire track and field into pieces, and then press the block by pavement. In order to ensure smooth drainage and less joints and other requirements, the use of the first outer ring after the construction process.

- Q: How does the waterproofing membrane work?

- 5, lap seam treatment: the roll is rolled, the adjacent two webs of the joints with a short stove welding welding sticky, heated to spill hot melt adhesive for the degree, and then use the flame and iron wipe The sub-joints will be evenly heated to wipe the edge; 6, the coil side of the sealing side of the construction.

Send your message to us

Micropore Insulation Board 1.Fire-retardant 2.Thermal-insulated

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords