Metallic Material Steel Rebar/ Deformed Steel bar /Building Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

HRB355 HRB400 HRB500 Hot Rolled Steel Rebars

Specifications

Diameter:6-50mm

Length:as your requirement

Application:construction/building

Standard:ASTM,JIS ,GB,BS.

Package: For 6-8mm, in coil. For 10-50mm, in straight-bar, usually 12m length

Table

| Name | steel rebar |

| Standard | ASTM,AISI, JIS GB,DIN,BS. |

| Grade | HRB335/400/500/400E/500E,Q235,BS/GR460B,JIS312SD390 |

| Diameter | 6,8,10,12,14,16,20,25,30,40,50mm |

| Length | 6,9,12m |

| MOQ | 25tons |

| Delivery time | within 30 days after order confirm |

| Payment | 30%TT deposit in advance the balance against the copy of B/L OR L/C at sight |

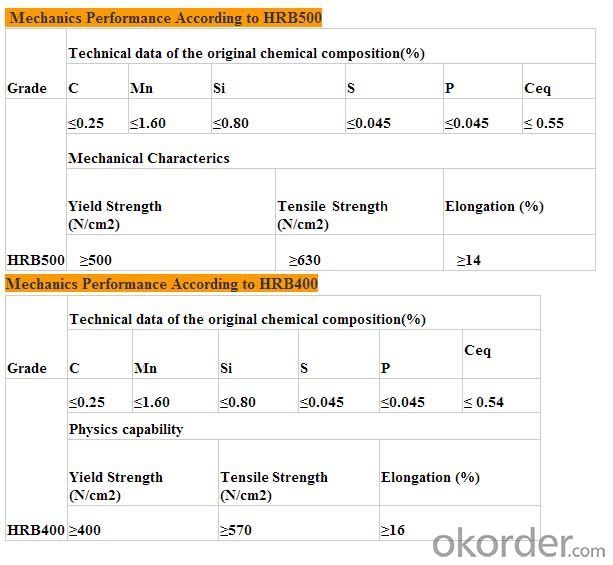

Chemical Parameters

Steel grade | C% ≤ | Si%≤ | Mn%≤ | P%≤ | S%≤ | Cr%> | Ceq≤ |

HRB335 | 0.17-0.25 | 0.40-0.80 | 1.00-1.60 | 0.045 | 0.045 | 0.3-0.4 | 0.52 |

HRB400 | 0.17-0.25 | 0.20-0.80 | 1.20-1.60 | 0.045 | 0.045 | 0.3-0.4 | 0.54 |

HRB500 | ≤0.25 | ≤0.80 | ≤1.6 | 0.045 | 0.045 | 0.3-0.4 | 0.55 |

Gr.60 | ≤0.30 | ≤0.40 | ≤1.00 | 0.050 | 0.050 | 0.3-0.4 |

Detail

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

We are a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

We provide the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: Can steel rebars be used in energy-efficient buildings?

- Yes, steel rebars can be used in energy-efficient buildings. Steel rebars are commonly used in construction to provide reinforcement to concrete structures. In energy-efficient buildings, steel rebars can be integrated into the design to enhance the structural integrity and durability of the building, while also minimizing energy consumption. Additionally, steel rebars can be recycled, making them a sustainable choice for energy-efficient construction.

- Q: How do steel rebars contribute to the overall stability of a structure?

- Steel rebars contribute to the overall stability of a structure by enhancing its strength and durability. These reinforcing bars are embedded within concrete to provide tensile strength, which is necessary to resist bending or cracking forces. They help distribute the applied loads evenly throughout the structure, preventing the formation of cracks and ensuring structural integrity. Additionally, rebars help prevent the structure from collapsing under extreme conditions, such as earthquakes or heavy winds, by increasing its ability to withstand these external forces.

- Q: What are the common applications of steel rebars?

- Steel rebars, or reinforcing bars, are commonly used in construction projects to provide strength and stability to concrete structures. Some common applications of steel rebars include reinforcing building foundations, columns, beams, and slabs. They are also used in the construction of bridges, highways, tunnels, and other infrastructure projects. Additionally, steel rebars are used in the production of precast concrete elements, such as precast panels and walls. Overall, steel rebars play a crucial role in enhancing the durability and structural integrity of concrete structures.

- Q: Are there any limitations on the use of steel rebars in flexural members?

- Yes, there are some limitations on the use of steel rebars in flexural members. One of the main limitations is related to the size and spacing of rebars. The design codes specify certain minimum and maximum sizes and spacing requirements to ensure proper reinforcement and prevent issues such as cracking or excessive deflection. Additionally, the type and grade of steel used for rebars must also comply with specified standards to ensure structural integrity and durability.

- Q: How do steel rebars affect the overall thermal stability of a structure?

- Steel rebars can significantly affect the overall thermal stability of a structure due to their thermal conductivity properties. Thermal stability refers to the ability of a structure to withstand changes in temperature without experiencing significant deformation or damage. Steel rebars have high thermal conductivity, which means they can efficiently transfer heat throughout a structure. This property can have both positive and negative effects on the thermal stability of the structure. On the positive side, steel rebars can help in dissipating heat from the structure, preventing the concentration of heat in specific areas. This can prevent localized thermal expansion, which can lead to cracks and structural failures. By evenly distributing heat, steel rebars can improve the overall thermal stability of the structure. On the negative side, steel rebars can also conduct heat to colder areas of the structure, leading to thermal gradients. This can result in differential expansion and contraction, causing stress and potential damage to the structure. Additionally, during fire incidents, steel rebars can rapidly heat up and transfer the heat to the surrounding concrete, reducing its strength and compromising the overall stability of the structure. To mitigate these potential negative effects, engineers and architects must carefully consider the design, placement, and spacing of steel rebars within the structure. By ensuring proper reinforcement layout and utilizing insulation materials, the thermal stability can be enhanced. Additionally, incorporating fire-resistant coatings or insulation around the rebars can help minimize the effects of heat transfer during fire incidents. In conclusion, steel rebars can significantly impact the overall thermal stability of a structure. While their high thermal conductivity can aid in dissipating heat, it can also lead to thermal gradients and potential damage. By carefully considering the design and incorporating appropriate measures, the negative effects of steel rebars on thermal stability can be minimized, ensuring the long-term durability and safety of the structure.

- Q: What are the common surface patterns for steel rebars?

- Plain, deformed, and ribbed patterns are the common surface patterns for steel rebars. Plain rebars have a smooth surface and no patterns or indentations. They are used in applications where bendability or weldability is important, such as in reinforced concrete structures. On the other hand, deformed rebars have patterns or indentations on their surface, such as ribs, humps, or indentations. These patterns enhance bonding with the surrounding concrete and improve the grip between the rebar and concrete. This ensures better stress transfer and prevents slippage. Deformed rebars are widely used in construction projects, particularly in areas that require high tensile strength and bond strength. Ribbed rebars, a specific type of deformed rebar, have continuous longitudinal ribs along their length. These evenly spaced ribs provide additional anchorage and bond strength with the concrete. Ribbed rebars are commonly used in applications that require a higher level of bond strength, such as in seismic zones or structures subjected to heavy loads. In conclusion, the choice of surface pattern for steel rebars depends on the specific requirements of the construction project and the desired performance characteristics.

- Q: How do steel rebars perform in heavy load-bearing structures?

- Steel rebars perform exceptionally well in heavy load-bearing structures. Due to their high tensile strength and durability, they provide crucial reinforcement to concrete, effectively distributing and resisting heavy loads. This ensures structural integrity, preventing deformation and collapse even under extreme conditions.

- Q: Can steel rebars be used in the construction of shopping complexes?

- Shopping complexes can indeed utilize steel rebars in their construction. These rebars are frequently employed as reinforcement in concrete structures, including shopping complexes, owing to their exceptional strength and capacity to bear heavy loads. By providing structural integrity, they bolster the overall robustness and longevity of the building. Furthermore, steel rebars possess corrosion resistance, a vital attribute for structures such as shopping complexes that face diverse weather conditions and extensive foot traffic. Additionally, the utilization of steel rebars permits flexibility in design and construction, empowering architects and engineers to fashion intricate and distinctive structures. In summary, steel rebars are a dependable and extensively utilized material for reinforcing concrete in the construction of shopping complexes.

- Q: How are steel rebars protected against electromagnetic interference?

- Steel rebars are typically protected against electromagnetic interference through the use of concrete coverings, which act as a barrier and shield against electromagnetic waves. Additionally, proper grounding techniques and the use of high-quality concrete can further enhance the protection against electromagnetic interference.

- Q: Are steel rebars suitable for use in tunnels and underground mines?

- Yes, steel rebars are suitable for use in tunnels and underground mines. Steel rebars provide excellent strength, durability, and resistance to corrosion, making them an ideal choice for reinforcing concrete structures in these challenging environments. Their ability to withstand high loads and seismic forces makes them reliable for ensuring the structural integrity and safety of tunnels and underground mines.

Send your message to us

Metallic Material Steel Rebar/ Deformed Steel bar /Building Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords