Melt Extract Stainless Steel Fiber - Straight Type Steel Fiber from CNBM China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

1. Material: low carbon steel wire or stainless steel

2.Diameter: 0.4mm-1.0mm

3.Length: meet your requirements

4.tensile strength >1000Mpa

6.Feature: excellent tensile,high tenacity,against cracking,impact and fatigue

7.Uses: highway road surface,tunnel,building,airport road surface and so on .

Straight Steel Fiber

1.ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

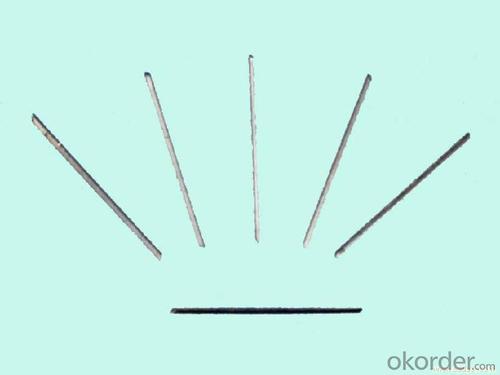

Picture

Steel fiber straight type

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: How does melt extract stainless steel fiber enhance the strength of concrete?

- Melt extract stainless steel fiber enhances the strength of concrete by providing reinforcement and improving its structural integrity. The fibers act as a secondary reinforcement, distributing the load more evenly throughout the concrete matrix. This reduces cracking and enhances the flexural and impact resistance of the concrete. Additionally, the high strength and corrosion resistance of stainless steel fibers ensure the durability and long-term performance of the concrete.

- Q: How does melt extract stainless steel fiber improve the resistance of concrete to impact loads?

- The impact resistance of concrete is improved by the addition of melt extract stainless steel fiber in various ways. Firstly, the tensile strength and ductility of the concrete are significantly enhanced by the inclusion of stainless steel fibers. Acting as reinforcement, these fibers distribute the applied load more evenly throughout the concrete and reduce the concentration of stress points, thus preventing crack formation and propagation and increasing the overall impact resistance of the concrete. Furthermore, the unique properties of stainless steel, including high strength, corrosion resistance, and durability, contribute to the improved impact resistance of the concrete. The stainless steel fibers are extremely tough and can withstand high impact forces without breaking or deforming. This toughness allows them to effectively absorb and dissipate energy during impact, preventing catastrophic failure. In addition, the small size and high aspect ratio of the melt extract stainless steel fibers promote better bonding with the concrete matrix. This strong bond ensures that the fibers remain securely anchored within the concrete, even under high impact loads. Consequently, the overall strength and integrity of the concrete are increased, making it more resistant to damage caused by impacts. Moreover, the addition of stainless steel fibers can also enhance the behavior of concrete after cracking. In the event of cracks occurring due to impact loads, the fibers help to hold the cracked sections together, preventing further separation and limiting the extent of damage. This post-cracking behavior further contributes to the overall improvement in the impact resistance of the concrete. To summarize, melt extract stainless steel fiber improves the impact resistance of concrete by enhancing its tensile strength, ductility, and toughness. The fibers ensure a more uniform distribution of applied loads, prevent crack formation and propagation, and provide a strong bond with the concrete matrix. Additionally, they are capable of absorbing and dissipating energy during impact and contribute to the post-cracking behavior of the concrete.

- Q: Does melt extract stainless steel fiber improve the ductility of concrete?

- Yes, melt extract stainless steel fiber does improve the ductility of concrete.

- Q: How much is the steel fiber bridge diversion dam using the model and specifications?

- Combined with the construction of the diversion tunnel on the left bank of the power station, the utilization principle, mix proportion design, construction technology, construction quality control and management of the wet sprayed steel fiber concrete are introduced.

- Q: Can melt extract stainless steel fiber be used in high-rise building construction?

- Yes, melt extract stainless steel fiber can be used in high-rise building construction. Stainless steel fibers are commonly used in concrete to improve its mechanical properties, including tensile strength, crack resistance, and impact resistance. In high-rise buildings, where structural integrity and durability are of utmost importance, the use of stainless steel fiber-reinforced concrete can provide several benefits. Firstly, stainless steel fibers enhance the ductility of concrete, making it more resistant to cracking under high loads or seismic activity. This is crucial in high-rise buildings, as any cracks in the structure could compromise its stability and safety. Secondly, stainless steel fibers also improve the concrete's resistance to corrosion. High-rise buildings are often exposed to harsh environmental conditions, such as humidity, saltwater, and pollutants, which can accelerate the corrosion of the reinforcement within the concrete. By incorporating stainless steel fibers, the concrete becomes more resistant to corrosion, thus increasing the lifespan of the building. Additionally, stainless steel fibers can improve the fire resistance of concrete. In the event of a fire, the fibers can help to control the spread of flames and reduce the structural damage caused by high temperatures. This is particularly important in high-rise buildings, where fire safety is a top priority. Overall, the use of melt extract stainless steel fiber in high-rise building construction can enhance the structural integrity, durability, and fire resistance of the concrete. It offers a reliable solution for reinforcing the concrete and ensuring the safety and longevity of the building.

- Q: What are the different types of melt extract stainless steel fibers available in the market?

- There are several different types of melt extract stainless steel fibers available in the market. Some of the most common types include: 1. Type 304 Stainless Steel Fibers: These fibers are made from a combination of iron, chromium, and nickel. They offer excellent corrosion resistance and are often used in applications where exposure to chemicals or moisture is a concern. 2. Type 316 Stainless Steel Fibers: These fibers are similar to Type 304, but they contain a higher amount of molybdenum, which provides even greater corrosion resistance. They are often used in more demanding environments, such as marine applications or in areas with high chloride concentrations. 3. Type 430 Stainless Steel Fibers: These fibers contain a higher amount of chromium and are known for their good resistance to oxidation and heat. They are often used in high-temperature applications, such as in furnaces or automotive exhaust systems. 4. Type 410 Stainless Steel Fibers: These fibers contain a higher amount of carbon, which gives them excellent wear resistance. They are often used in applications where abrasion or wear is a concern, such as in concrete reinforcement or in industrial equipment. 5. Type 420 Stainless Steel Fibers: These fibers contain a higher amount of carbon and are often heat treated to increase their hardness. They are commonly used in applications where high strength and wear resistance are required, such as in cutting tools or in high-load bearing structures. It is important to note that the availability of these different types of melt extract stainless steel fibers may vary depending on the supplier and the specific requirements of the application. It is recommended to consult with a knowledgeable supplier or engineer to determine the most suitable type for a particular project.

- Q: How does melt extract stainless steel fiber improve the durability of nuclear power plant concrete?

- Enhancing the durability of nuclear power plant concrete is an essential function of melt extract stainless steel fiber. These fibers are specifically designed to withstand the harsh conditions present in nuclear power plants, including exposure to radiation, extreme temperatures, and high levels of moisture. One way in which melt extract stainless steel fiber improves the durability of nuclear power plant concrete is by reinforcing its structural integrity. By adding these fibers, the tensile strength of the concrete is increased, making it more resistant to cracking and spalling. This is particularly important in nuclear power plants, as any damage to the concrete can have severe consequences for the facility's safety and operation. Additionally, the unique properties of stainless steel fibers make them highly resistant to corrosion. Nuclear power plants are exposed to corrosive elements, such as chemicals and moisture, which can gradually deteriorate the concrete. Incorporating melt extract stainless steel fiber into the concrete mix significantly reduces the risk of corrosion, ensuring the long-term durability of the structure. Another advantage of melt extract stainless steel fiber is its ability to enhance the concrete's resistance to thermal stress. As nuclear power plants operate at high temperatures, the concrete structures must be able to withstand expansion and contraction. By adding these fibers, thermal stresses are distributed more evenly, preventing cracks and maintaining the overall integrity of the concrete. Furthermore, melt extract stainless steel fiber effectively mitigates the effects of radiation on nuclear power plant concrete. The fibers act as a radiation shield, absorbing and dispersing harmful radiation that can penetrate the concrete. This not only protects the structural integrity of the concrete but also maintains the safety of plant personnel and the surrounding environment. In conclusion, melt extract stainless steel fiber is crucial in improving the durability of nuclear power plant concrete. By reinforcing structural integrity, resisting corrosion, enhancing resistance to thermal stress, and mitigating the effects of radiation, these fibers ensure the long-term performance and safety of the concrete structures in nuclear power plants.

- Q: What is the effect of melt extract stainless steel fiber on the plastic shrinkage of concrete?

- The use of melt extract stainless steel fiber in concrete has a positive effect on mitigating plastic shrinkage. Plastic shrinkage refers to the volume reduction of concrete during the early stages of curing, often caused by evaporation of water from the surface. When melt extract stainless steel fibers are added to concrete, they provide reinforcement and increase the tensile strength of the material. This reinforcement helps to reduce the formation of cracks and shrinkage in the concrete, as the fibers act as a network that holds the concrete together. The stainless steel fibers also improve the overall durability and resistance of the concrete to external factors such as temperature changes, chemical exposure, and mechanical stress. This enhanced durability further reduces the potential for plastic shrinkage, as the concrete is less prone to cracking and deformation. Additionally, the melt extract stainless steel fibers improve the overall workability and flowability of the concrete mix. This improved workability allows for better compaction and reduces the risk of segregation, which can contribute to plastic shrinkage. Overall, the incorporation of melt extract stainless steel fiber in concrete helps to mitigate plastic shrinkage by providing reinforcement, improving durability, and enhancing workability. This results in a more robust and resilient concrete structure with reduced shrinkage and cracking.

- Q: Can melt extract stainless steel fiber improve the resistance of concrete to fire?

- Yes, melt extract stainless steel fiber can improve the resistance of concrete to fire. Stainless steel fibers are known for their high melting point and excellent heat resistance properties. When added to concrete, they can enhance its ability to withstand high temperatures and prevent spalling, cracking, and structural failure during a fire. The fibers act as reinforcement, improving the overall fire resistance of the concrete and extending its durability under extreme heat conditions.

- Q: What is the effect of melt extract stainless steel fiber on the flexural toughness of shotcrete?

- The effect of melt extract stainless steel fiber on the flexural toughness of shotcrete is an increase in the overall toughness and crack resistance of the material. The stainless steel fibers reinforce the shotcrete, preventing the propagation of cracks and enhancing its ability to withstand bending and flexural stresses. This results in improved durability and structural integrity of the shotcrete, making it more suitable for applications where flexural toughness is important, such as tunnel linings or retaining walls.

Send your message to us

Melt Extract Stainless Steel Fiber - Straight Type Steel Fiber from CNBM China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords