Melt Extract Stainless Steel Fiber Concrete Steel Fiber from CNBM China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

Place of Origin: Tianjin, China (Mainland)

Model Number: 0.5

Material: Steel

Production Process: Cold drawn

Lengh: 30

Type: 1

Compressive Strength: >1200MPa

Aspect ratio: 60

Standard: ASTM A820M-11

Section Shape: Circular

Application: Concrete Reinforcement

Packaging & Delivery

| Packaging Details: | 20 kg/Bag,50 bags/Pallet or 1,000kg/ Bulk Bag |

|---|---|

| Delivery Detail: | 1 Month |

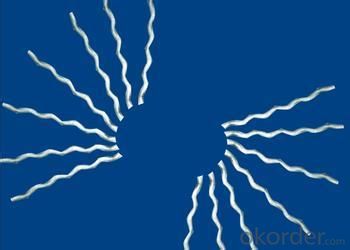

Product Description

| Diameter | 0.75 mm | ||

| Length | 60 mm | ||

| Aspect Ratio | 80 | ||

| Tensile strength | 1200 MPa | ||

| Type | Cold drawn Steel Fiber | ||

| End | Hooked-end Steel Fiber | ||

| Glued/Loose | Glued Steel Fiber | ||

| Bending Angle | 45°(min.30°) | ||

| Usage & Performance | Floor:Trafficked areas and Industrial floors | ||

| Shotcrete :Slope stabilization and Final lining | |||

| Precast concrete:Pipe and Railway sleepers | |||

| Packing | Standard Export Pallet Packing | Bag Packing | 20 kg/Bag,50 bags/Pallet |

| Bulk Packing | 1,000kg/ Bulk Bag | ||

| Loading Quantity | 20’GP | 20-25 Tonne/Tonnes | |

| 40’GP | 25-27 Tonne/Tonnes | ||

| 40’HQ | 25-27 Tonne/Tonnes | ||

| MOQ | 1 kg for trial order | ||

| Supply Ability | 10,000 Tonne/Tonnes per Year | ||

| Payment Terms | T/T or L/C at sight | ||

| Delivery Time | Within 15 days after receiving deposit or original L/C at sight | ||

| Certification | ISO9001:2000, CE, | ||

| Product | Diameter (mm) | Length (mm) | Aspect Ratio | Type | Packing |

| G-6030 | 0.5 | 30 | 60 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6535 | 0.55 | 35 | 65 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6035 | 0.6 | 35 | 60 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-8060 | 0.75 | 60 | 80 | Glued | 20 kg/Bag, 50 bags/Pallet |

| G-6060 | 0.9 | 60 | 60 | Glued | 20 kg/Bag, 50 bags/Pallet |

| G-6030 | 0.5 | 30 | 60 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6535 | 0.55 | 35 | 65 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6035 | 0.6 | 35 | 60 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-8060 | 0.75 | 60 | 80 | Loose | 20 kg/Bag, 50 bags/Pallet |

| G-6060 | 0.9 | 60 | 60 | Loose | 20 kg/Bag, 50 bags/Pallet |

- Q: Does melt extract stainless steel fiber improve the resistance to freeze-thaw cycles of concrete?

- Concrete's resistance to freeze-thaw cycles is indeed improved by melt extract stainless steel fiber. By incorporating stainless steel fibers into the concrete, its durability and performance are enhanced as the detrimental effects of freeze-thaw cycles are minimized. When water freezes within the concrete, it expands and applies pressure on the surrounding matrix, leading to cracks and eventual deterioration of the structure. Nonetheless, the inclusion of melt extract stainless steel fibers helps address these issues. These fibers serve as reinforcement within the concrete, imparting additional strength and preventing crack propagation. This reinforcement effectively boosts the concrete's resistance to the damaging effects of freeze-thaw cycles. Moreover, melt extract stainless steel fibers possess exceptional corrosion resistance properties, further contributing to the concrete's improved durability. Unlike other fiber types, stainless steel fibers do not corrode or degrade over time, ensuring their long-term effectiveness in enhancing freeze-thaw resistance. In summary, the addition of melt extract stainless steel fiber significantly enhances concrete's resistance to freeze-thaw cycles, preventing cracks and extending the structure's lifespan.

- Q: How does melt extract stainless steel fiber improve the freeze-thaw resistance of concrete?

- An innovative material known as melt extract stainless steel fiber greatly improves the freeze-thaw resistance of concrete. This particular fiber is obtained from stainless steel using a specialized extraction process that guarantees its purity and high-quality characteristics. When concrete is subjected to freezing and thawing cycles in cold weather conditions, its ability to withstand these cycles is referred to as freeze-thaw resistance. Freezing water within the concrete expands, exerting pressure on the surrounding material. Over time, this pressure can lead to cracks, spalling, and other forms of deterioration in the concrete structure. By incorporating melt extract stainless steel fibers into the concrete mix, several mechanisms work together to enhance its freeze-thaw resistance. Firstly, these fibers act as reinforcement within the concrete matrix, providing additional tensile strength and reducing the formation and spread of cracks. As a result, the overall structural integrity of the concrete is preserved even when exposed to freeze-thaw cycles. Furthermore, the stainless steel composition of these fibers offers excellent resistance to corrosion. Concrete is often exposed to various environmental factors, including chloride ions from de-icing salts, which can accelerate the corrosion process. However, the use of stainless steel fibers prevents the corrosion of embedded reinforcing steel, thereby maintaining the durability and freeze-thaw resistance of the concrete. Moreover, the presence of melt extract stainless steel fibers improves the overall durability of the concrete. These fibers enhance the cohesion and bond between the aggregate and cement paste, resulting in a denser and less permeable concrete matrix. This reduces the entry of water and other harmful substances, such as chloride ions, into the concrete, further protecting it against freeze-thaw damage. In conclusion, melt extract stainless steel fiber plays a vital role in enhancing the freeze-thaw resistance of concrete. Through reinforcement, corrosion resistance, and improved durability, these fibers effectively mitigate the negative effects of freeze-thaw cycles on concrete structures, ensuring their longevity and integrity.

- Q: What is the effect of melt extract stainless steel fiber on the modulus of creep of concrete?

- Including melt extract stainless steel fibers in concrete has a favorable impact on the material's creep modulus. Stainless steel fibers are renowned for their excellent tensile strength, resistance to corrosion, and durability. When integrated into concrete, these fibers serve as reinforcement, thereby enhancing its mechanical characteristics. The creep modulus denotes the material's capacity to withstand deformation over a prolonged period under a consistent load. By incorporating stainless steel fibers, the concrete's resistance to creep is enhanced as the fibers aid in load distribution and reduction of internal stresses within the material. Consequently, the rate of creep diminishes and the creep modulus increases. Furthermore, the presence of melt extract stainless steel fibers also enhances the concrete's overall ductility. This implies that the material can endure greater deformation before experiencing failure, leading to improved structural stability and performance. This is particularly advantageous in situations where the concrete is subjected to sustained loads or temperature fluctuations, as it mitigates the risk of long-term deformation and potential structural failure. In conclusion, the inclusion of melt extract stainless steel fibers has a positive effect on the concrete's creep modulus. Their addition improves the material's resistance to deformation over time, enhances its mechanical properties, and augments its overall durability.

- Q: How does melt extract stainless steel fiber improve the resistance to fatigue in shotcrete?

- The resistance to fatigue in shotcrete is enhanced by melt extract stainless steel fiber, which adds extra reinforcement to the concrete matrix. Shotcrete, commonly used in construction projects that require high strength and durability, is prone to fatigue and cracking due to repeated loading and cyclic stresses. By including melt extract stainless steel fibers in the shotcrete mix, the overall fatigue resistance of the material is significantly improved. These fibers act as discrete reinforcement, distributing the applied stresses more evenly throughout the concrete. This helps prevent the formation and spreading of cracks, thereby enhancing the overall durability and lifespan of the shotcrete structure. The effectiveness of melt extract stainless steel fibers in enhancing fatigue resistance is due to their unique properties. These fibers are made from high-quality stainless steel, which possesses excellent tensile strength and corrosion resistance. Additionally, the manufacturing process ensures that the fibers have a smooth surface and uniform geometry, allowing for better bonding with the concrete matrix. Moreover, the addition of melt extract stainless steel fibers can also enhance the flexural strength of shotcrete, making it more resistant to bending and flexing stresses. This is particularly crucial in applications such as tunnel linings, underground structures, and retaining walls, where shotcrete is subjected to significant cyclic loading. To summarize, melt extract stainless steel fiber improves the resistance to fatigue in shotcrete by providing additional reinforcement, distributing stresses more evenly, and reducing the formation and propagation of cracks. As a result, shotcrete structures become more durable and long-lasting, capable of withstanding cyclic loading and maintaining their structural integrity over time.

- Q: Does melt extract stainless steel fiber improve the resistance to sulfate attack of concrete?

- Yes, melt extract stainless steel fiber can improve the resistance to sulfate attack of concrete. Sulfate attack is a chemical reaction between sulfate ions and the materials present in the concrete, which can lead to deterioration and decreased durability. By adding stainless steel fibers, the concrete becomes more resistant to sulfate attack due to the corrosion-resistant properties of stainless steel. The fibers act as a reinforcement, enhancing the overall strength and durability of the concrete and reducing the potential for sulfate attack. Additionally, the stainless steel fibers can help prevent cracks from forming, which further reduces the likelihood of sulfate ions penetrating the concrete and causing damage. Overall, the addition of melt extract stainless steel fibers can significantly improve the resistance to sulfate attack in concrete structures.

- Q: What is the effect of melt extract stainless steel fiber on the fire resistance of concrete?

- The use of melt extract stainless steel fiber in concrete significantly enhances its fire resistance. The fiber acts as reinforcement, improving the concrete's structural integrity and preventing cracking or spalling under high temperatures. It also helps to disperse heat more evenly throughout the concrete, reducing the risk of localized hotspots. Additionally, the stainless steel fiber provides a barrier against the penetration of flames and gases, further enhancing the fire resistance of the concrete. Overall, incorporating melt extract stainless steel fiber in concrete greatly improves its ability to withstand and resist fire.

- Q: What are the advantages of using melt extract stainless steel fiber?

- The advantages of using melt extract stainless steel fiber include increased strength and durability, improved resistance to corrosion and high temperatures, enhanced crack resistance and impact resistance, and the ability to reinforce and stabilize concrete and other materials. Additionally, stainless steel fiber offers excellent electrical conductivity and electromagnetic shielding properties, making it suitable for various industrial applications.

- Q: How does melt extract stainless steel fiber enhance the flexural strength of concrete?

- The flexural strength of concrete is enhanced by the inclusion of melt extract stainless steel fiber, which reinforces the material throughout. When mixed into the concrete, the stainless steel fibers disperse evenly within the matrix, creating a network of reinforcement in three dimensions. These fibers play a crucial role in increasing the tensile strength of the concrete, which is especially important in applications involving bending and cracking forces. Similar to miniature reinforcement bars, the fibers prevent cracks from spreading and enhance the concrete's resistance to bending. Furthermore, the stainless steel fibers improve the bond between the concrete matrix and any aggregates or other reinforcement elements present. This strengthened bond facilitates the efficient transfer of stress and load, further improving the flexural strength of the concrete. The unique properties of stainless steel, including its high tensile strength, corrosion resistance, and ductility, make it an ideal material for enhancing the flexural strength of concrete. These fibers effectively bridge micro-cracks that may occur during the drying and hardening process, preventing them from developing into larger cracks under load. In summary, melt extract stainless steel fiber reinforces the concrete matrix, bolstering its ability to withstand bending and cracking forces. This improvement in flexural strength enables the construction of more durable and resilient concrete structures, particularly in applications where flexibility and crack resistance are vital, such as beams, slabs, and other structural elements.

- Q: How does melt extract stainless steel fiber affect the thermal conductivity of concrete?

- Melt extract stainless steel fiber can significantly affect the thermal conductivity of concrete. The addition of these fibers to concrete increases its thermal conductivity, meaning that heat can be conducted more efficiently through the material. This is mainly due to the high thermal conductivity of stainless steel, which is much higher than that of concrete. When melt extract stainless steel fibers are mixed into concrete, they act as conductive pathways for heat to travel through the material. As a result, the overall thermal conductivity of the concrete increases, allowing for better heat transfer and distribution. This enhanced thermal conductivity can have various benefits in concrete applications. For instance, in structures where thermal management is critical, such as in high-rise buildings or infrastructure exposed to extreme temperatures, the addition of stainless steel fibers can help regulate and dissipate heat more effectively. This can help prevent the build-up of excessive heat, reducing the risk of thermal expansion and potential structural damage. Furthermore, the improved thermal conductivity of concrete with stainless steel fibers can also enhance the efficiency of heating or cooling systems in buildings. By facilitating better heat transfer, the concrete can act as a more effective thermal mass, absorbing and releasing heat more efficiently, thereby reducing energy consumption and enhancing comfort levels. However, it is important to note that the impact of melt extract stainless steel fibers on thermal conductivity may vary depending on factors such as fiber content, fiber length, and fiber distribution within the concrete mix. Proper design and testing are essential to ensure the desired thermal performance is achieved.

- Q: How does melt extract stainless steel fiber improve the durability of concrete?

- Melt extract stainless steel fiber improves the durability of concrete in several ways. Firstly, the addition of stainless steel fibers to concrete enhances its tensile strength and flexural properties. This means that the concrete becomes more resistant to cracking and can withstand higher levels of stress and load. The fibers act as reinforcement within the concrete matrix, effectively bridging any cracks that may occur and preventing them from propagating further. Moreover, stainless steel fibers also improve the impact resistance of concrete. The fibers absorb and distribute the impact energy, reducing the likelihood of surface spalling or fragmentation. This makes the concrete more durable and able to withstand heavy impacts or dynamic loading conditions. Additionally, stainless steel fibers enhance the resistance of concrete to corrosion. These fibers are made from stainless steel, which is highly resistant to rust and other forms of corrosion. By incorporating stainless steel fibers into the concrete mix, it creates a protective barrier against aggressive chemicals, moisture, and other environmental factors that can cause corrosion and deterioration. This significantly extends the lifespan of the concrete structure and reduces the need for costly repairs or replacements. In summary, melt extract stainless steel fiber improves the durability of concrete by enhancing its tensile strength, flexural properties, impact resistance, and corrosion resistance. This ultimately leads to a longer-lasting and more resilient concrete structure that can withstand harsh conditions and heavy use.

Send your message to us

Melt Extract Stainless Steel Fiber Concrete Steel Fiber from CNBM China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords