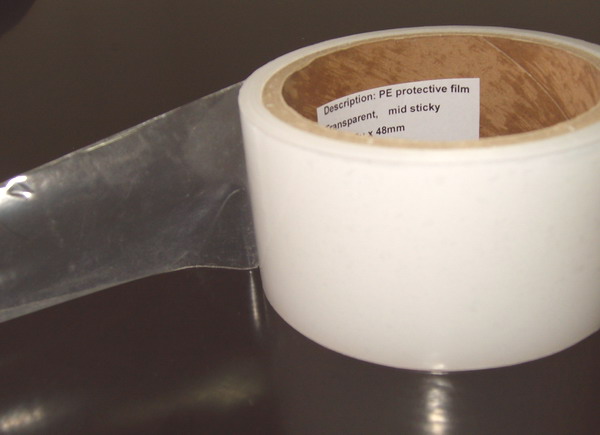

Medium Tack PE protective flim HN-80

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Construction: LDPE film + water based acrylic

Total Thickness (adhesives + carrier):80+10%micron

Colour: Black & White

Density 0.95g /cm3

Tensile Strength (Long): >18N/25mm

Tensile Strength (Trasv): >13N/25mm

Adhesion (to stainless steel):150g/25mm

Elongation at break-MD: >200%

Elogation at break-CD: > 350%

Static Shear 23 DC: >48 hours

Storage: 35 DC

Humidity: 80%

Shelf: 6 months

- Q: What's the meaning of 3.0 H in anti-scratch protective film 3.0H?

- It's similar to pencil 3.0 H, meaning hardness degree is 3.0.

- Q: I am a beauty shop, into a number of forming universal car door, bowl, protective film, but how all paste is not good, not wrinkled, that is, there are bubbles can not get out, what is a good way to paste it?

- You won't first ask an expert to come over and stick to it once. If you learn it once more, don't you OK?

- Q: Generally, what processes are needed when producing finished protective films? ?

- According to materials, protective films can be classified into PET film, PE film, PVC film, PP film (including OPP and CPP films), etc. This is common way used in industry. Apart from this, some also classify the films according to things like adhesion, thickness, colors as well as the ways of use. As for their use, protective films are used during production, processing and packaging of the finished products. The key point is to see what the clients use these films for. It's determined by the processing of the clients. All in all, the clients use the films to protect their products from scratches, dirt and moisture and to impove the quality and competitiveness of their products.

- Q: How do you keep the film on the refrigerator for a long time?

- I do the refrigerator, and I tell you a professional way. First, buy a roll of sticky adhesive tape

- Q: How can the protective film on the outer layer of the stainless steel thermos cup be removed?

- 5. With hand cream. First, the surface of the printed products tear off, and then put some hand cream on the top, slowly rub with your thumb, rub for a while, you can rub the stainless steel protective film on the residual gum are rubbed down. Just slow down. Hand cream is a kind of grease, which is not compatible with gum. Remove glue is to use this characteristic.

- Q: Mobile phone protection film paste, and then ripped off, but also paste it? How should I post it?

- Methods / steps1 first package with a small cloth to clean the dust on the surface of the screen, wipe when, in order to from side to side do not wipe, wipe back and forth; note: first removed a small cloth on the small grain or lint cloth and then wipe.2, the general screen has three layers of film, choose the right size of the film, remove the bottom layer, (really useful is the middle layer), and then stick to the mobile phone screen, carefully stick down.

- Q: What does the pl mean in Protective film pl - 1255 - s pl?

- Pl is the name of manufacturer. Its meaning is similar to KM film.

- Q: How to deal with the stains on mobile phone protective film?

- I usually apply something like alcohol, gasoline or liquid detergent to the protective film using a cotton ball and then wipe the liquid up with a cotton swab.

- Q: How to remove the protective film on PCM plate in a quick way?

- PCM plate can be coated with film using machine. But you can only tear off the film by hands. There is no such machine that can remove the film for you.

Send your message to us

Medium Tack PE protective flim HN-80

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords