China BOPP Packaging Tape Masking Film for Car Painting SGS and ISO

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 30000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

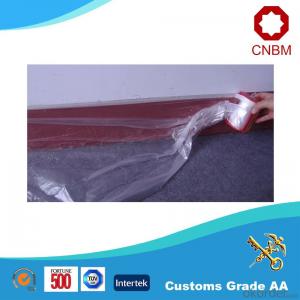

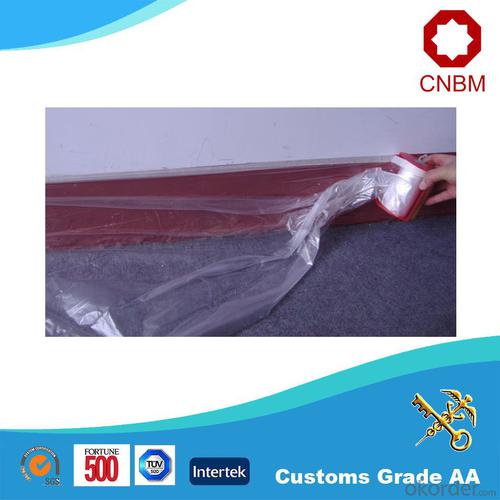

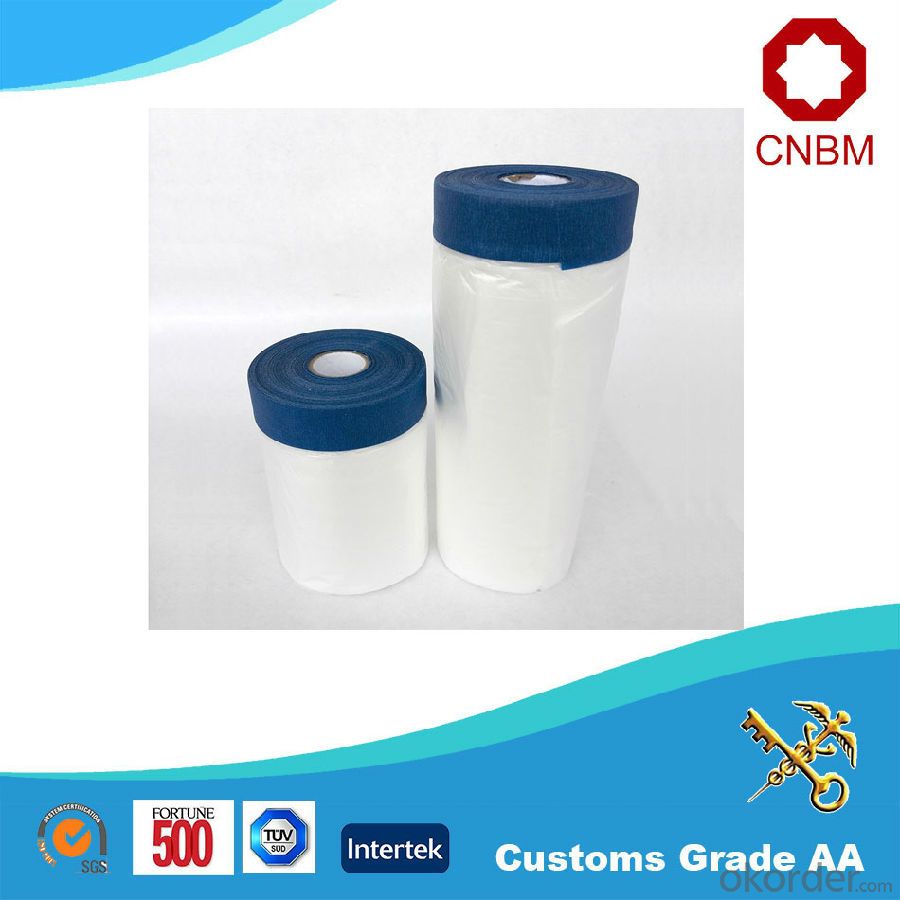

Masking Film For Car Painting SGS and ISO

1. Structure of Masking Film Description

Masking Film is of HDPE film and masking tape. Pretaped with Masking Tape, which is sunlight stable and gives the user 7-day clean removal. A convenient, pretaped plastic film which unfolds to cover and protect various surfaces while painting. Specially treated film clings to surfaces and is easy to clean up.

2. Main Features of Masking Film

Multi-Folded easy to use;

Strong and Flexible;

Competitive price

Sunlight stable even on glass

Indoor/outdoor painting

3. Masking Film Images

4. Masking Film Specification

Tape Size | Rolls/Carton | Weight/Roll(kg) | Jointing Material | Temperature Resistance |

330mm*30M | 20 | 0.12 | Crepe parer | -5—60°C |

550mm*30M | 50 | 0.17 | Crepe parer | -5—60°C |

1100mm*30M | 25 | 0.30 | Crepe parer | -5—60°C |

1400mm*30M | 10 | 0.39 | Crepe parer | -5—60°C |

5. FAQ

Q1. What is our company?

CNBM International Corporation is a state-owned company. As World Top 500 Company, we have clients from over 120 countries and overseas branches in 5 countries. We specialized in adhesive tape for over 20 years, with SGS and ISO9001 certified and Grade AA for Export.

Q2. Packing and shipping

It is wraped by hot shrink POF film with adhesive lable. 50 rolls or 25rolls packing in to one carton.

After receiving the deposite, it will take around 20 days before shippment.

Q3. Why choose us?

20 Years Experience USD1.6 billion yearly sales

World Top 500 Enterprise

OEM service, supported by strong R&D team

A short lead time

Quality guarantee with third party certification

One-step service: transportation, capital etc.

- Q: What is the difference between acrylic and hot melt adhesive for packaging tape?

- Packaging tape commonly utilizes two types of adhesives: acrylic and hot melt. These adhesives possess distinct characteristics that set them apart. A significant disparity lies in their bonding strength. Hot melt adhesive boasts exceptional bonding strength, making it ideal for heavy-duty applications. It creates a robust and durable bond that can withstand rigorous handling and varying temperatures. Conversely, acrylic adhesive typically offers a lower level of bonding strength in comparison. While still suitable for most general packaging requirements, it may not be the best choice for heavy or bulky items. Another distinction can be found in the application process. Hot melt adhesive is applied in a molten state and solidifies once cooled. Typically, it is dispensed using a hot melt glue gun or applicator. The quick setting time of hot melt adhesive allows for swift packaging operations, making it popular in high-volume settings. On the other hand, acrylic adhesive is applied in a liquid form and requires some time to cure and establish a strong bond. It can be applied using a hand dispenser or tape gun, and optimal adhesion often necessitates some pressure. Moreover, hot melt adhesive demonstrates excellent adhesion to a wide array of surfaces, including cardboard, plastics, and metals. Its versatility allows for usage with various packaging materials. While acrylic adhesive also adheres well to different surfaces, it may not exhibit the same level of compatibility with certain low-energy surfaces, such as polyethylene or polypropylene. Furthermore, temperature resistance is an essential factor to consider. Hot melt adhesive performs admirably in both high and low temperatures, maintaining its bonding strength. It can endure freezing temperatures and heat without compromising its adhesive properties. Acrylic adhesive, while generally offering good temperature resistance, may not be as effective in extreme conditions, particularly at very high or low temperatures. In conclusion, the primary disparities between acrylic and hot melt adhesives for packaging tape lie in bonding strength, the application process, surface compatibility, and temperature resistance. While hot melt adhesive provides superior bonding strength, rapid setting time, and excellent temperature resistance, acrylic adhesive offers versatility, ease of application, and good adhesion to most surfaces. The choice between the two depends on specific packaging needs, materials used, and environmental conditions.

- Q: Can packaging tape be used for sealing retail or product packaging?

- Yes, packaging tape can be used for sealing retail or product packaging.

- Q: Can packaging tape be used for sealing perishable food items?

- Using packaging tape to seal perishable food items is not recommended. This is because packaging tape is typically made of materials like polypropylene or PVC, which are not suitable for food safety and may contaminate the food. Additionally, packaging tape is not designed to create an airtight seal, which is essential for preserving the freshness and preventing spoilage of perishable food items. To ensure the safety and quality of perishable food items, it is advisable to use appropriate food-safe sealing methods such as ziplock bags, airtight containers, or food-grade cling wrap.

- Q: Can packaging tape be used for sealing plastic food containers?

- Yes, packaging tape can be used for sealing plastic food containers. However, it is important to note that using food-grade adhesive tapes specifically designed for sealing food containers is recommended to ensure safety and maintain the quality of the food.

- Q: Can packaging tape be used for sealing metal boxes?

- Yes, packaging tape can be used for sealing metal boxes. Packaging tape is designed to provide a secure and durable seal on various surfaces, including metal. It offers a strong adhesive that can effectively stick to metal surfaces, ensuring that the box remains sealed during transportation or storage. However, it is important to choose a packaging tape that is suitable for heavy-duty applications and can withstand the weight and pressure that may be exerted on the metal box. Additionally, it is recommended to clean the metal surface before applying the tape to ensure proper adhesion.

- Q: Can packaging tape be used for sealing furniture or home goods?

- Yes, packaging tape can be used for sealing furniture or home goods. Packaging tape is designed to provide a secure and strong seal, making it suitable for various purposes including sealing boxes and packages. When used on furniture or home goods, packaging tape can help keep the item protected during transportation or storage. It is important to ensure that the tape is applied properly and that it does not damage the surface or leave any residue. Additionally, depending on the weight and size of the item, it might be more appropriate to use specialized tapes or techniques for sealing furniture or home goods to ensure maximum protection.

- Q: I'd like to know the specifications of the sealing tape. How do you see it? (the following two examples) product name: sealing tape product type: 2.5 inch product specifications: 57mm*80 code (8.5mm thick) weight: about 0.145KG the price for volume: Specifications: code number 48mm*150 meters *40u flesh 20mm here refers to what? I know that 40U means stickiness, so how do I see that?

- 48mm refers to the width of the tape, 150 meters /80 yards, refers to the length of plastic bags (one yard =0.9144 meters)

- Q: How does packaging tape perform on rough or uneven surfaces?

- Packaging tape typically does well on rough or uneven surfaces, thanks to its adhesive properties that allow it to stick firmly to most surfaces, even those that aren't perfectly smooth. The tape is designed to mold itself to the shape of the surface, ensuring a tight seal and preventing any possible lifting or peeling. However, it's important to note that the effectiveness of packaging tape on rough or uneven surfaces can vary depending on the specific type and quality of the tape being used. Some tapes may have stronger adhesion or more flexible backing materials, which can further improve their performance on rough or uneven surfaces. In certain situations, it may be necessary to apply more pressure or use multiple layers of tape to ensure a secure bond. Moreover, it's worth considering alternative packaging materials, like stretch film or strapping, for particularly rough or irregular surfaces, as they may offer a more dependable solution.

- Q: How do I prevent packaging tape from tearing during application?

- To prevent tearing of packaging tape during application, there are several measures that can be taken: 1. Opt for the appropriate type of packaging tape: It is essential to select a high-quality packaging tape that is specifically designed for heavy-duty applications. Look for tapes that are explicitly labeled as tear-resistant or reinforced. 2. Prepare the surface adequately: Before applying the tape, ensure that the surface is thoroughly cleaned, dried, and devoid of any dust or debris. A dirty or uneven surface can easily cause the tape to tear. 3. Employ the correct technique: When applying the tape, hold the roll at a slight angle in relation to the surface rather than perpendicular. Applying it at an angle will minimize friction between the tape and the surface, thus reducing the likelihood of tearing. 4. Apply gentle pressure: Apply the tape smoothly and evenly, exerting gentle pressure. Avoid pulling or tugging excessively, as it can strain the tape and increase the risk of tearing. 5. Steer clear of extreme temperatures: Extreme temperatures can have an impact on the adhesive properties of the tape, rendering it more susceptible to tearing. If possible, store the tape in a controlled environment and refrain from using it in excessively hot or cold conditions. 6. Consider utilizing a tape dispenser: Employing a tape dispenser can facilitate smoother and more even application of the tape, thereby minimizing the chances of tearing. It also offers improved control and reduces strain on the tape. 7. Cut the tape precisely: When cutting the tape, employ a sharp blade or scissors to ensure a clean cut. A jagged or uneven cut can weaken the tape and make tearing more likely. By adhering to these suggestions, the likelihood of packaging tape tearing during application can be significantly reduced, guaranteeing a secure and dependable seal for your packages.

- Q: Is packaging tape safe to use on leather?

- Packaging tape is not recommended for use on leather. While it may temporarily hold leather pieces together, using packaging tape can cause damage to the leather over time. The adhesive on packaging tape can leave behind residue that is difficult to remove and can stain or discolor the leather. Additionally, the strong adhesive can weaken the leather, leading to tears or permanent damage. It is best to use leather-specific adhesives or methods when working with leather to ensure its longevity and preservation.

Send your message to us

China BOPP Packaging Tape Masking Film for Car Painting SGS and ISO

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 30000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords