Painting Packaging Tape - BOPP Tape 50 Micron Blue Colour SGS Certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 600 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

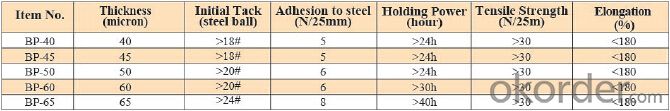

Typical Physical Reports of Masking Tape

Description

The Bopp Tape is of Bopp film as the carrier, coating with water based acrylic adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

The thickness of the tape can be customized.

Application

General purpose of Bopp Tape: widely used for carton sealing and packaging, light duty packaging, bounding, holding and other office and household use.

Packaging & Delivery

Packaging Detail:

Log Roll: Width1280mm; length according to customers’ requirements

Cut Roll: As per customer’s requirements

Delivery Detail: within 10-12 working days after receiving your deposit

Service

Sample of Bopp Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service

Well-trained & experienced sales representative are ready to answer you.

About us

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Welcome to contact us and visit the factory!

- Q: What are the considerations for using packaging tape on delicate surfaces?

- When using packaging tape on delicate surfaces, there are several considerations to keep in mind. Firstly, it is important to choose the right type of tape. Opt for a tape specifically designed for delicate surfaces, such as low-tack or painter's tape. These tapes are typically less sticky and have a gentler adhesive that won't damage or leave residue on sensitive materials like paper, fabric, or painted surfaces. Secondly, before applying the tape, ensure that the surface is clean and free from any dust, dirt, or moisture. This will prevent any particles or contaminants from getting trapped under the tape and potentially causing damage. When applying the tape, be cautious and gentle. Avoid pressing down too hard or stretching the tape excessively, as this can increase the risk of tearing or damaging the delicate surface. Take your time and carefully smooth out any wrinkles or air bubbles to ensure proper adhesion. Additionally, it is advisable to test the tape on a small, inconspicuous area of the delicate surface before fully committing to using it. This will help you assess its compatibility and whether it causes any adverse effects or damage. Lastly, when removing the tape, do so slowly and carefully. Pull the tape back at a low angle, parallel to the surface, to minimize the risk of tearing or leaving any residue behind. If any residue does remain, use a gentle adhesive remover or warm soapy water to clean the surface. By considering these factors, you can effectively use packaging tape on delicate surfaces without causing any harm or leaving unwanted marks or residue.

- Q: Is packaging tape safe to use on plastic shower curtains?

- Yes, packaging tape is generally safe to use on plastic shower curtains. It is designed to adhere to a variety of surfaces, including plastic. However, it is important to consider the specific type of plastic used in your shower curtain and the condition of the tape. If the plastic is sensitive or easily damaged, it is advisable to test a small area first to ensure that the tape does not cause any discoloration or damage. Additionally, if the shower curtain is regularly exposed to water or moisture, it is recommended to use a waterproof or water-resistant tape to prevent any potential issues. Overall, as long as the plastic is not easily damaged and the tape is in good condition, packaging tape can be a safe and effective option for temporarily securing or repairing plastic shower curtains.

- Q: How does the tape used for packing the finished product in the workshop be accounted for?

- Adhesive tape for packaging of finished goods in workshopBorrow: recycled material - packagingTaxes payable - VAT payable - VAT

- Q: Can packaging tape be used for sealing plastic flower pots?

- Yes, packaging tape can be used for sealing plastic flower pots. It provides a strong adhesive bond that can effectively seal any gaps or cracks in the pot, ensuring that the soil and water stay securely within the pot. However, it is important to note that using a more suitable adhesive, such as waterproof silicone or specialized pot sealants, would be a better long-term solution for sealing plastic flower pots.

- Q: Is packaging tape safe to use on photographs?

- Packaging tape can be safely used on photographs when applied correctly and handled with care. Nevertheless, it is not advisable to use packaging tape on valuable or irreplaceable photographs. This is due to the potential risks of leaving residue or adhesive marks on the photos, which could lead to damage or deterioration of the image over time. It is recommended to opt for archival-quality materials that are specifically designed for preserving photographs, like acid-free photo corners or photo-safe adhesive. These alternatives guarantee the long-term safety and preservation of the photographs without causing any harm.

- Q: Can packaging tape be used for sealing plastic or poly bags?

- Yes, packaging tape can be used for sealing plastic or poly bags. Packaging tape is specifically designed to provide a strong and secure seal on various surfaces, including plastic and poly bags. It has an adhesive backing that adheres well to the plastic material, ensuring that the bag remains tightly sealed. However, it is important to note that there are different types of packaging tape available, so it is recommended to choose a tape specifically designed for sealing plastic or poly bags to ensure optimal performance and long-lasting seal.

- Q: Can packaging tape be used for sealing wooden furniture?

- Yes, packaging tape can be used for sealing wooden furniture, but it is not the most suitable option. Packaging tape is not specifically designed for sealing wood and may not provide a long-lasting or aesthetically pleasing seal. It is recommended to use appropriate wood sealants or adhesives specifically made for wooden surfaces for better results.

- Q: What are the alternatives to packaging tape for sealing packages?

- There are several alternatives to packaging tape for sealing packages. Here are a few options: 1. Gummed tape: Gummed tape, also known as water-activated tape, is a popular alternative. It is made of paper or reinforced material and requires water to activate the adhesive. Gummed tape forms a strong bond with the package and provides a tamper-evident seal. 2. Strapping: Strapping is commonly used for securing heavy or bulky packages. It involves using plastic or metal straps to hold the package tightly together. Strapping can be more secure than tape, especially for larger or irregularly shaped items. 3. Shrink wrap: Shrink wrap is a plastic film that can be wrapped around the package and sealed using heat. As the film shrinks, it tightly conforms to the shape of the package, providing a secure seal. Shrink wrap is commonly used for wrapping pallets or bundling multiple items together. 4. Adhesive labels: Adhesive labels can be used as an alternative to tape for sealing packages. These labels have a strong adhesive backing that sticks to the package, providing a secure seal. They are especially useful for small or lightweight items. 5. Twine or string: For lighter packages, twine or string can be used to secure the contents. Simply wrap the string around the package multiple times and tie it securely. While this method may not be as strong as tape, it can be a cost-effective and eco-friendly option. Ultimately, the choice of alternative to packaging tape depends on the size, weight, and nature of the package. Each option has its own advantages and disadvantages, so it's important to consider the specific requirements of the shipment before making a decision.

- Q: Can packaging tape be used for sealing envelopes?

- Yes, packaging tape can be used for sealing envelopes. Packaging tape is designed to provide a secure seal on boxes and packages, but it can also be used effectively to seal envelopes. It offers strong adhesive properties, ensuring that the envelope remains sealed during transit. However, it is important to note that packaging tape may not be the most aesthetically pleasing choice for sealing envelopes, as it is typically wider and less transparent than traditional envelope-sealing options such as glue sticks or clear tape.

- Q: How does packaging tape perform in high humidity environments?

- Packaging tape tends to work effectively in environments with high humidity, although its performance depends on the specific type and quality of the tape. Most packaging tapes are designed to withstand moisture and humidity to some degree, as they are commonly used in various climates and conditions. However, extended exposure to high humidity can weaken the adhesive properties of the tape, causing it to lose its effectiveness in sealing packages. In environments with high humidity, the moisture in the air can have an impact on the tape's ability to securely adhere. The adhesive on the tape may become less sticky or fail completely, resulting in the tape peeling off or losing its grip on the packaging. This can lead to packages becoming unsealed, potentially resulting in damage or loss of contents during transportation or storage. To minimize the effects of high humidity, it is advisable to use packaging tapes specifically designed for such conditions. There are tapes available that have been specifically formulated with adhesives resistant to moisture or have been reinforced with additional layers to enhance their strength and durability in humid environments. These tapes are capable of maintaining their adhesive properties even when faced with high levels of humidity. It is also important to store packaging tapes properly in a controlled environment with low humidity when they are not being used. Exposure to excessive moisture or humidity can negatively impact the tape's performance even before it is applied to packages. Storing the tape in a cool and dry place can help preserve its integrity and ensure it remains effective when needed. In conclusion, although packaging tape generally performs well in high humidity environments, it is essential to consider the quality and type of tape being used. Opting for moisture-resistant or reinforced tapes and storing them appropriately can help maintain their effectiveness in sealing packages, even in challenging humidity conditions.

Send your message to us

Painting Packaging Tape - BOPP Tape 50 Micron Blue Colour SGS Certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 600 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords