Marine Grade 3003 H14 Aluminum Coil with High Quality 5083 Aluminum Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Marine Grade Aluminum Plate 5083 Description:

We can produce aluminum sheet,color aluminum sheet and plastic composite panel base material. They are widely used in construction and decoration, hardware and electric appliances manufacture, automobile manufacture and other industrial and civil purposes, such as electronic capacitor, rice cooker, refrigerator, computer casting, lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc.

2.Main Features of Marine Grade Aluminum Plate 5083 :

Anodised aluminium sheet

Mirror finish aluminium sheet

Stucco aluminium sheet

Competitive Price

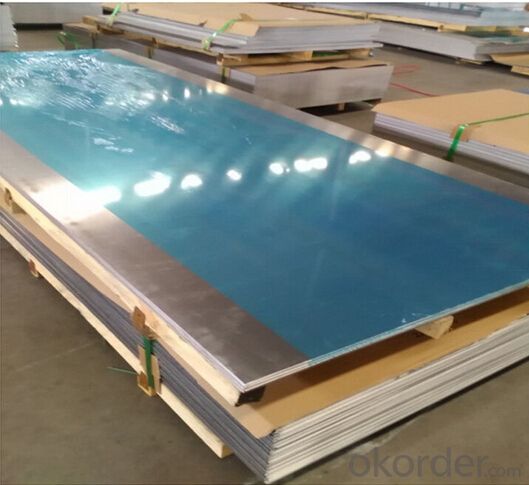

3. Marine Grade Aluminum Plate 5083 Images:

4. Marine Grade Aluminum Plate 5083 Specification:

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: What is the shelf life of aluminum coils?

- The shelf life of aluminum coils can vary depending on various factors such as storage conditions, handling, and the specific alloy used. Generally, aluminum coils can have a shelf life of several years if stored properly. It is recommended to store them in a dry and clean environment, away from moisture, extreme temperatures, and corrosive substances. Additionally, handling should be done with care to prevent any damage or contamination that may reduce the shelf life. Regular inspection and maintenance are also important to ensure the integrity and longevity of aluminum coils. Ultimately, consulting the manufacturer's guidelines or contacting a professional in the industry can provide more accurate information on the specific shelf life of aluminum coils.

- Q: Can aluminum coils be used for marine applications?

- Yes, aluminum coils can be used for marine applications. Aluminum has excellent corrosion resistance properties, making it suitable for marine environments. It is lightweight, durable, and can withstand exposure to saltwater, making it a popular choice for boats, ships, and other marine structures.

- Q: Can aluminum coils be used in the production of aluminum louvers?

- Yes, aluminum coils can be used in the production of aluminum louvers. Aluminum coils are typically used as a raw material in various manufacturing processes, including the production of aluminum louvers. They can be easily formed and shaped into the desired louver design, offering durability and corrosion resistance.

- Q: Can aluminum coils be customized or fabricated into specific shapes?

- Indeed, it is possible to customize or fabricate aluminum coils into desired shapes. Aluminum possesses remarkable formability and can be effortlessly shaped through diverse fabrication techniques such as rolling, bending, stamping, and extrusion. By employing these processes, aluminum coils can be converted into specific forms like sheets, plates, tubes, and profiles to cater to the unique demands of different applications. Moreover, aluminum can also be welded, joined, or cut to further tailor its shape and dimensions. The adaptability of aluminum coils in terms of customization renders them highly favored across various industries, including automotive, aerospace, construction, and manufacturing.

- Q: Can aluminum coils be recycled multiple times without losing their properties?

- Yes, aluminum coils can be recycled multiple times without losing their properties. Aluminum is a highly recyclable material and can be melted down and reused indefinitely without any significant degradation in its properties. This makes aluminum coils a sustainable and environmentally friendly choice for various applications.

- Q: How do aluminum coils compare to copper coils in terms of conductivity?

- The conductivity properties of aluminum coils and copper coils differ. Copper is renowned for its exceptional electrical conductivity, making it the preferred option for applications where maximum efficiency is vital, like electrical wiring and motor windings. In comparison, copper coils possess a considerably higher electrical conductivity than aluminum coils. Consequently, copper coils can transmit electricity more efficiently, resulting in decreased power losses and enhanced overall performance. Conversely, aluminum coils exhibit lower electrical conductivity when compared to copper coils. Although aluminum is still a capable conductor of electricity, it is not as efficient as copper. This implies that aluminum coils may experience increased power losses and reduced efficiency in contrast to their copper counterparts. Nevertheless, aluminum coils possess their own advantages in certain applications, such as being lighter and more cost-effective. Ultimately, the choice between aluminum and copper coils hinges on the specific requirements of the application, with copper being favored for its superior conductivity properties.

- Q: An they say aluminum can cause breast cancer in some.

- You bet it does......its a compound called aluminum chlorhydrate. Its made by reacting aluminum with hydrochloric acid. Actually they use aluminum hydroxide to prevent a potential explosion hazard during the manufacturing process. Aluminium-based complexes (chlorhydrates) react with the electrolytes in the sweat to form a gel plug in the duct of the sweat gland. The plugs prevent the gland from excreting liquid and are removed over time by the natural sloughing of the skin. The aluminum salts interact with the keratin fibrils in the sweat ducts and form a physical plug that prevents sweat from reaching the skin’s surface. Aluminum salts also have a slight astringent affect on the pores; causing them to contract, further preventing sweat from reaching the surface of the skin. The blockage of a large number of sweat glands reduces the amount of sweat produced in the underarms, though this may vary from person to person. Aluminum is considered a heavy metal and has been shown (in its elemental form only) to alter the physiology of the blood-brain barrier. Antiperspirants are considered drugs by the FDA and no test yet performed shows a link between Aluminum chlorhydrate and breast cancer, brain cancer or any other cancer for that matter. Hey, you asked......

- Q: What are the different surface finishes for pre-painted aluminum coils?

- The different surface finishes for pre-painted aluminum coils include smooth, textured, embossed, brushed, and metallic finishes.

- Q: What are the elements and compounds that make up aluminum coils?

- <p>Aluminum coils are primarily composed of the element aluminum (Al), which is a lightweight, silvery-white, and ductile metal. Pure aluminum is relatively soft, so it is often alloyed with other elements to improve its strength and durability. Common alloying elements include copper, magnesium, manganese, silicon, and zinc. These elements can enhance properties like strength, formability, and resistance to corrosion. The specific composition of an aluminum coil can vary depending on the alloy type and the intended application, but the primary component will always be aluminum.</p>

- Q: Hi i need to know what will happen to the impact strength of aluminum 2024 reinforced with Silicon carbide is treated to cryogenic temperature (nearly -200C). Will impact strength increase or decrease. Also will the impact strength vary with respect to the percentage of Silicon carbide.

- Aluminum 2024 doesn't have a transition temperature, it absorbs about 18n-m impact strength (via charpy tests I ran three weeks ago at my College course). This was constant between -150?C to +150°C (liquid nitrogen to a furnace). This excerpt from wiki: Cutting tools In 1982 at the Oak Ridge National Laboratories, George Wei, Terry Tiegs, and Paul Becher discovered a composite of aluminium oxide and silicon carbide whiskers. This material proved to be exceptionally strong. Development of this laboratory-produced composite to a commercial product took only three years. In 1985, the first commercial cutting tools made from this alumina and silicon carbide whisker-reinforced composite were introduced by the Advanced Composite Materials Corporation (ACMC) and Greenleaf Corporation. Leads me to believe it depends on how you mix the material in would make a difference. Silicon Carbide and aluminum make very strong tools, but would make it more brittle. The ceramic in a metallic crystal lattice (metal is a crystalline structure) would allow more voids to coalesce leading to a brittle fracture, but the initial strength would be improved because of substitution dislocations in the crystal structure (it would be more rigid, stronger, but more prone to sudden failure). Silicon carbide has low thermal expansion coefficient compared to aluminum also so when it gets really cold the aluminum would contract around the particles increasing the strength, but again, reducing ductility and causing fractures to occur more rapidly. Anyways, very interesting, you should do a bit of research on your own after this as I gave you some good places to work from (and I'm sure plenty of words to look up ;D )

Send your message to us

Marine Grade 3003 H14 Aluminum Coil with High Quality 5083 Aluminum Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords