Manhole Covers Ductile Iron EN124 GGG40 B125 On Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Cast Iron Manhole Cover Description :

A manhole cover is a removable plate forming the lid over the opening of a manhole, to prevent anyone or anything from falling in, and to keep out unauthorized persons and material.

Manhole covers are often made out of cast iron, concrete or a combination of the two. This makes them inexpensive, strong, and heavy, usually weighing more than 50 kilograms (110 lb). The weight helps to keep them in place when traffic passes over them, and makes it difficult for unauthorised people not having suitable tools to remove them.

2.Main Features of the Ductile Iron Manhole Cover:

1) Product information:

Manhole Covers are manufactured for construction and public use. Manhole Covers shall be smooth and free from sand holes, blow holes, distortion or any other defects

2) Material

a) Ductile Iron GGG500-7 & 400-12

b) Grey Iron GG20

3) Designs .

a) EN124 A15, B125, C250, D400, E600 and F900

b) A60005 for casting design

c) Major standards designs available

d) As per customers' drawings or samples

4) Process

c) Molding boards

d) Green sand with hand molding

5) Coating

a) Cold applied black bitumen

b) Without coating

c) Coating as per customers' requirement

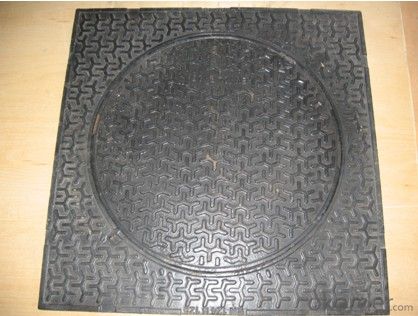

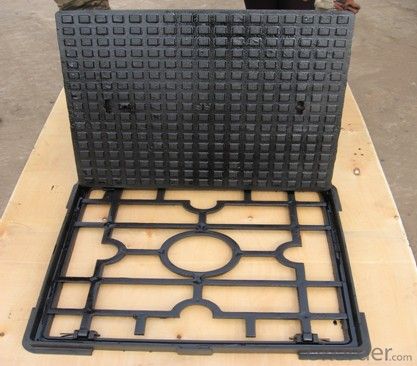

3.Manhole Cover Images:

4.Manhole Cover Specifications:

Manhole cover are manufactured for construction and public use. Manhole cover shall be smooth and free sand holes, blow holes, distortion or any other defects

A) Ductile iron GGG50

B) Grey iron GG20

A) EN124 Class B125 C250 D400 F 900, with different size and grammage, or as customers' requirement.

B) as per customers' drawing or samples

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

Q. Can I fit a square manhole cover into a round chamber?

A. Yes, there are a select few manhole covers which are square-to-round, meaning they will fit square or round chambers.

Q. I have a heavy traffic manhole cover but it has been broken by a forklift, why?

A. Forklifts have solid wheels which apply pressure differently to standard pneumatics and therefore covers must be specially adapted to suit this.

Q. I’ve measured my clear opening size but none of your covers match it, can you offer anything?

A. It’s likely that your cover is quite old and in imperial measurements which are no longer manufactured. However, we can offer bespoke solutions with manhole covers made to the specification you require.

Q. The project I’m working on requires a manhole cover with a quality finish, what’s available?

A. Naturally, galvanised steel of black polypropylene aren’t always ideal, and so we offer brass or stainless steel edging, as well as complete stainless steel covers.

- Q: How is the silicon sol precision casting part priced? What is the price per ton of casting? Such as 304 material.

- The material is usually steel material price plus the cost (per ton of 2.5-3 million, plus profit).In the Yangtze River Delta region, generally 304 casting price of about 5-5.5 million / ton.The price will be higher if the parts are complex, or a piece weighs less than 100 grams.

- Q: Why do cheap cars like stamping parts instead of casting parts?

- Separation process is also called blanking, the purpose is to make the stamping parts along a certain contour line from the sheet metal separation, at the same time guarantee the quality requirements of the separation section. Stamping is a highly efficient production methods, the use of compound die, especially the multi station progressive die stamping process can be completed in a multi machine, realized by belt uncoiling, leveling, punching, forming and finishing automatic production. High production efficiency, good working conditions, low production costs, can produce hundreds of parts per minute. The purpose of forming processes is to allow the sheet to undergo plastic deformation without breaking the billet and to make the desired shape and size. In actual production, a variety of processes are often applied to a workpiece. Blanking, bending, shearing, drawing, bulging, spinning, and straightening are the main types of stamping machines.

- Q: What is the reason for 304 stainless steel precision casting parts to be changed?

- 304 stainless steel is easier to change than ordinary steel. Because the 304 heat conductivity is lower than that of the low doped steel, the temperature is even more uneven, and 20% of the non ferrous elements also make the distribution of internal and external elements more uneven, hard and soft inside. Each of these two produces greater internal stresses, resulting in a variant.

- Q: What's the density of the cast iron? The density is thin and the density is thin

- There is a hot knot in the thick area, which easily causes microscopic shrinkage and makes the casting not dense. A riser may be added for shrinkage relief.

- Q: What are the causes of pitting on the surface of a precision casting?

- There is a bump on the mold. Or casting cooling fast.

- Q: We are small castings, the need for surface treatment of shot blasting machine, about how much?

- according to the comprehensive consideration of factors such as yield, size of workpiece commonly used on the market the crawler shot blasting machine has Q324, Q326, Q328, Q3210, and each time the amount of their treatment were 125KG, 200KG, 400KG, 600KG, the specific use of what types also need to be determined according to the actual situation

- Q: When there is no flaw detection for large casting parts, is there any crack inside?

- According to the industry standards, within the scope of the standard requirements to determine whether the product is qualified

- Q: Is 316 casting better than 304 casting?

- The degree of difficulty in the process of casting depends mainly on the structure, precision requirements, and hardness of the casting.

- Q: How to solve casting defect casting?

- Different defects, different solutions, some shortcomings, the current domestic level can not be resolved

- Q: What's the cause of the choking of the casting?,

- 3. when casting the environment is humid, sand mold has not removed the moisture, when the casting, the moisture instantaneous transforms into the steam, causes the blowhole

Send your message to us

Manhole Covers Ductile Iron EN124 GGG40 B125 On Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords