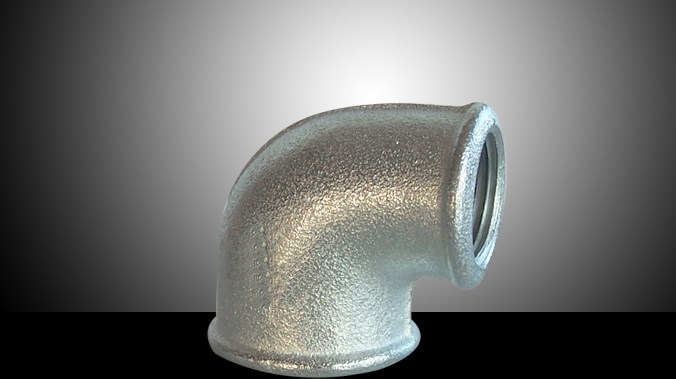

Malleable Iron Pipe Fitting Hot Dipped Galvanized on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. hydraulic hose crimping machine in Electrical equipment&supplies

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelt,and chemical industry.

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

2. Antiflaming,fire-resistance rubber hose assembly

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer and laye

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelts,and chemical industry

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

3. hydraulic hose Universal Wire-braided DN6

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

· Model Number: GB/T3683-92

Packaging & Delivery

Packaging Details: | hydraulic hose is wrapped with fabrics |

Delivery Detail: | 80000meters/30days |

Specifications

Universal Wire-braided Hydraulic Hose, Q/FLT01-AStandard GB/T3683-92, Temperature range: -40 to +100

Universal Wire-braided Hydraulic Hose

Q/FLT01-AStandard GB/T3683-92

Tube: oil resistant synthetic rubber

Reinforcement: 1 W/B (one high tensile steel wire braid)

Cover: abrasion and weather resistant synthetic rubber

Temperature range: -40 to +100.

4. Drilling Rubber Hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Drilling hose

DN |

Hose I.D | Wire O.D |

Hose O.D |

Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | Length | |||

inch | mm | mm |

mm | MPa | psi | MPa | psi | mm | kg/m | metres | |

5 | 3/16 | 4.8 | 9.5 | 11.8 | 25.0 | 3630 | 100.0 | 14280 | 89 | 0.19 | 50/100 |

6 | 1/4 | 6.4 | 11.1 | 13.4 | 22.5 | 3270 | 90.0 | 12840 | 102 | 0.21 | 50/100 |

8 | 5/16 | 7.9 | 12.7 | 15.0 | 21.5 | 3120 | 85.0 | 12280 | 114 | 0.24 | 50/100 |

10 | 3/8 | 9.5 | 15.1 | 17.4 | 18.0 | 2615 | 72.0 | 10280 | 127 | 0.33 | 50/100 |

13 | 1/2 | 12.7 | 18.3 | 20.6 | 16.0 | 2320 | 64.0 | 9180 | 178 | 0.41 | 50/100 |

16 | 5/8 | 15.9 | 21.4 | 23.7 | 13.0 | 1890 | 52.0 | 7420 | 203 | 0.45 | 50/100 |

19 | 3/4 | 19.0 | 25.4 | 27.7 | 10.5 | 1530 | 42.0 | 6000 | 241 | 0.58 | 50/100 |

25 | 1 | 25.4 | 33.3 | 35.6 | 8.8 | 1280 | 35.0 | 5020 | 305 | 0.88 | 50 |

32 | 11/4 | 31.8 | 40.5 | 43.5 | 6.3 | 920 | 25.0 | 3600 | 419 | 1.23 | 20/40 |

38 | 11/2 | 38.1 | 46.8 | 50.6 | 5.0 | 730 | 20.0 | 2860 | 508 | 1.51 | 20/40 |

51 | 2 | 50.8 | 60.2 | 64.0 | 4.0 | 580 | 16.0 | 2280 | |||

5. Concrete pump rubber hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Specifications

High Quality Concrete Pump Delivery Rubber Hose

1.high quality

2.ISO9001:2008

3.reasonable price

1. Material: Black NR and BR synthetic rubber .

2.Reinforcement:Spiral textile/steel wire.

3. Widely application: Schwing PM SANY Zoomlion and other brand concrete pump trucks.

4.Cover:Abrasion resistantant,heat and ozone resistant.

5.Inside diameter:50-152mm

6.Working pressure:8.5 MPA.

7.Detailed specification:

No | Description | ID | OD | Plies | Working Pressure | Burst Pressure | Weight |

1 | 2 inch | 50mm | 70mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 3.5kgs |

2 | 2.5 inch | 63mm | 88mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 4.9kgs |

3 | 3 inch | 76mm | 102mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 6.5kgs |

4 | 4 inch | 100mm | 130mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 9.3kgs |

5 | 5 inch | 125mm | 155mm | 2 or 4 | 8.5MPA 1200PSI | 20MPA 3000PSI | 10.9kgs |

6 | 6 inch | 152mm | 184mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 13.3kgs |

- Q: Can ductile iron pipes be used for bridge piers?

- Yes, ductile iron pipes can be used for bridge piers. Ductile iron pipes are known for their high strength and durability, making them suitable for various applications, including bridge construction. They have excellent resistance to corrosion and can withstand heavy loads, making them a reliable choice for supporting bridge piers. Additionally, ductile iron pipes offer ease of installation and maintenance, which can be advantageous in bridge construction projects. However, it is important to consider the specific requirements and design specifications of the bridge before selecting ductile iron pipes as the material for bridge piers. Proper engineering evaluation and consideration of factors such as load capacity, soil conditions, and environmental factors are essential to ensure the suitability and safety of using ductile iron pipes for bridge piers.

- Q: Are ductile iron pipes suitable for bridge crossings or crossings under roadways?

- Bridge crossings or crossings under roadways can be easily accommodated with ductile iron pipes. These pipes possess remarkable strength, durability, and resistance against external forces like heavy traffic loads and bridge movements. With their high tensile strength, they can endure the stress and strain caused by vehicles passing over them. Furthermore, ductile iron pipes exhibit exceptional corrosion resistance, rendering them suitable for underground installations that may come into contact with water or other corrosive elements. Additionally, their long lifespan and minimal maintenance requirements make them a dependable choice for bridge crossings or crossings under roadways. Consequently, ductile iron pipes offer a cost-effective and efficient solution for such infrastructure projects.

- Q: Can ductile iron pipe be used for high-pressure gas systems?

- Ductile iron pipe is a viable option for high-pressure gas systems due to its remarkable strength and durability. Its ability to withstand high pressures makes it suitable for applications requiring such systems. It possesses outstanding mechanical properties, including high tensile strength, yield strength, and impact resistance. These properties enable it to endure the pressures associated with gas transmission. Additionally, its resistance to corrosion ensures its reliability for long-term use in high-pressure gas systems. However, to ensure optimal safety and performance, it is crucial to consider the specific requirements and regulations of the gas system and seek guidance from industry professionals for correct installation and maintenance of the ductile iron pipe.

- Q: What is the acceptance of cast iron pipe material?

- A cast pipe made of cast iron. Cast iron pipes are used for water supply, drainage and gas transmission lines. They include cast iron pipes and pipe fittings. Labor intensity is small.

- Q: What is the expected pressure rating for ductile iron pipes?

- The expected pressure rating for ductile iron pipes can vary depending on various factors such as the pipe diameter, wall thickness, and the specific application it is being used for. However, generally speaking, ductile iron pipes are designed and manufactured to withstand high-pressure conditions. They are commonly used in water and wastewater systems, where they can typically handle pressures ranging from 150 psi (pounds per square inch) up to 350 psi or even higher. It is important to consult the manufacturer's specifications or relevant industry standards for specific pressure ratings based on the pipe's size and application to ensure safe and reliable operation.

- Q: Ductile iron pipe connection mode

- Main points of installation: (1) clean the pipe mouth: clean all the sundries in the mouth. Second, clean aprons, aprons on the adhesive material on the apron: clean up, put the ring bending "plum blossom" or "8" shaped into a socket groove, and hand along the entire ring press again, or with a rubber hammer, to ensure that each part of the warping apron is not twisted, evenly the card in the slot.

- Q: How does ductile iron pipe compare to PVC pipe in terms of strength?

- Generally, ductile iron pipe is considered stronger than PVC pipe due to its composition of iron and carbon, which provides it with high tensile strength and resistance to breakage. It is commonly utilized in heavy-duty applications like water mains, sewer lines, and industrial piping due to its ability to withstand high pressures. On the flip side, PVC pipe is manufactured using a plastic material known as polyvinyl chloride. While PVC pipe is lightweight and easy to handle, it lacks the strength of ductile iron pipe. It is typically used in low-pressure applications such as household plumbing, irrigation systems, and drainage pipes. When comparing the strength of ductile iron pipe to PVC pipe, the former has a greater capacity to handle heavy loads, endure ground movement, and resist damage from external factors like rocks or tree roots. Additionally, ductile iron pipe is more durable and has a longer lifespan in comparison to PVC pipe. However, it is important to consider that the choice between ductile iron pipe and PVC pipe ultimately depends on the specific requirements of the project. Factors such as cost, environmental conditions, ease of installation, and desired longevity should all be taken into account when determining the appropriate type of pipe to utilize.

- Q: How does ductile iron pipe perform in areas with high seismic activity?

- Ductile iron pipe possesses exceptional strength and durability, making it an ideal choice for areas with high seismic activity. Seismic events, such as earthquakes, can exert significant stress and strain on pipelines, leading to rupture or failure. However, ductile iron pipe's unique material properties enable it to withstand these dynamic forces. One of the main advantages of ductile iron pipe in seismic regions is its remarkable flexibility. Unlike rigid materials like cast iron or steel, ductile iron exhibits a higher degree of elasticity. This allows it to deform and absorb energy during seismic events, dissipating the seismic forces and reducing the risk of pipe failure. Consequently, damage to the overall pipeline system is minimized. Furthermore, ductile iron pipe is manufactured with a high level of ductility, meaning it can undergo substantial deformation without fracturing. This characteristic is particularly crucial in seismic zones as it enables the pipe to endure ground movements and seismic waves without compromising its structural integrity. Additionally, the ability of ductile iron to absorb and redistribute stress helps prevent localized failures, ensuring the pipeline system's overall stability and reliability. Additionally, ductile iron pipe possesses excellent corrosion resistance, which is especially vital in high seismic areas where ground movement and subsequent water leaks can compromise the pipe's integrity. The corrosion resistance of ductile iron ensures the longevity and reliability of the pipeline system, minimizing the risk of leaks or failures during seismic events. In conclusion, ductile iron pipe performs exceptionally well in areas with high seismic activity due to its superior flexibility, high ductility, and corrosion resistance. These properties allow the pipe to withstand the dynamic forces generated during seismic events, providing a reliable and long-lasting solution for fluid transportation and ensuring the safety of communities in earthquake-prone regions.

- Q: Are ductile iron pipes resistant to UV radiation?

- Ductile iron pipes do not possess resistance against UV radiation. The exposure to UV radiation can lead to the deterioration and weakening of the material as time goes by. In order to safeguard ductile iron pipes from UV radiation, they must be covered or enveloped with a UV-resistant substance or coated with an appropriate protective layer. Furthermore, it is essential to conduct regular inspections and maintain the pipes adequately to identify and rectify any indications of UV damage.

- Q: What is the difference between cast iron pipe and seamless steel pipe and galvanized steel pipe?

- Galvanized steel pipe: divided into cold galvanized steel pipe, hot galvanized steel pipe, cold galvanized steel pipe has been banned, and the latter is also advocated by the state for the time being. In 60s and 70s, developed countries began to develop new types of pipes, and galvanized pipes were banned. China's Ministry of construction and other four ministries also issued a civilization, indeed from two, 000 years since the galvanized pipe as a water supply pipe, the New District cold water pipe has rarely used galvanized pipe, and some of the hot water pipe is galvanized pipe. Hot dip galvanized steel pipe is widely used in fire, power and highway.

Send your message to us

Malleable Iron Pipe Fitting Hot Dipped Galvanized on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords