magnesium oxide board heat prevention material incorporated

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

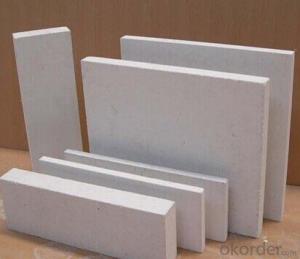

Fireproof Mgo board Perlite Panel

1.2400*1200mmSize

2.Density:950-1100kg/m3

3.light weight

4.Fireproof and moistureproof

DESCRIPTION

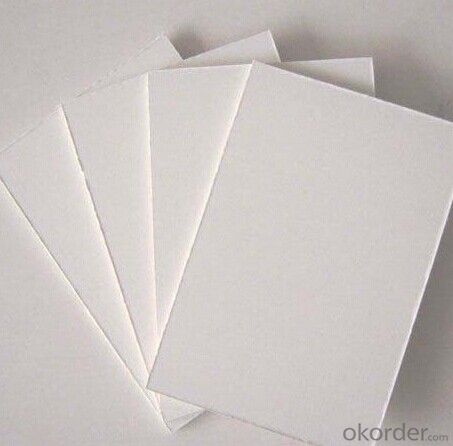

MgO board is made from Magnesium Oxide(MgO), Magnesium Chloride(Mgcl2), fiberglass mesh, sawdust, perlite etc.,using highly purified active MgO as the main fireproof material of board, high-quality MgCl2 as the main cementing material to solidify other materials, alkali-resistance fiberglass mesh to ensure the high strength of board, soft sawdust and light non-combustible perlite as filling materials.

It is a kind of Eco-friendly fireproof board widely used in construction and decoration.

(Pave slurry on the surface of MGO board to reduce the holes, make the surface more smoothness and less holes. Slurry paved board is a kind building material to further process.Suit to stick thin decorative material or paint on the board.)

APPLICATION

Partition and ceiling in the room, office building, hotel, hospital, airport, subway, gymnasium, library, museum, theater, factory building, computer laboratory, indoor natatorium. It is also used as the backing-lining, fireproof door and other wallboard, outdoor bill-board; base plate of various kinds of plaques; outside board of the ventilation shaft and the steel construction; roof boarding; electric wire and cable wraps up and applies etc.

FEATURE

1. Fireproof

It was tested by the National Center for Quality Supervision and Testing of Fire Building Materials (NFTC). Its fireproof level is rated level A (nonflammable level)

2. Dam proof

It is excellent in moisture-resistance. Dry bending strength is 15Mpa. Bending strength under absorbed moisture is 22Mpa.

3. Heat insulation

It has heat prevention material incorporated, it has great feature of heat prevention. Thermal resistance is 1.14m2k/w.

4. Soundproof

It is proved to have good noise insulation property after inspected by the National Center for Quality Supervision and Testing of Fire Building Materials (NFTC), The noise insulation factor of the wall can reach 44dB and 47dB. It has the best noise insulation constitution in China, especially the 95mm wall comprised by the 10mm board.It is light, it can save time, space, weight and expense. It is a new and high efficient wall.

5. Compact resistance

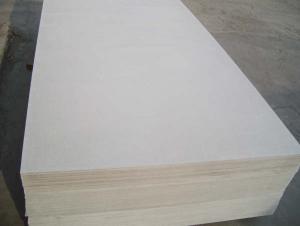

It is a light board. Its density is less than 1000kg/m3. At the same time its bending strength and impact resistance is excellent. Also, it will maintain its' quality during construction.

SPECIFICATION

1. Size: 1200*2400mm 1220*2440mm 1200*3000mm

2. Thickness: 3mm to 20mm

3. Notes:other specifications is available.

TECHNICAL DATA

Density | 0.95-1.15g/cm³ |

Bending strength | 19.5MPa |

Typical moisture content | 6% |

Drying shrinkage | 0.26% |

Moisture movement | 0.50% |

Impact strength | 6.2KJ/m² |

Pull put force of Screw | 37.1N/mm |

Non combustible performance | According to GB8624-1997, Combustibility is A1 Class. |

Fire rating limited | 6mm:>2Hours; 12mm:>4Hours; |

Thermal Coefficient | 0.109W/(m.k) |

- Q: Now I have to come up with a E1 level test report, but I want to buy E0 level, but the staff of Loulan Ya said that there is no E0 level of this concept. Is this true? Please industry experts to answer the next

- Of course, with the use of non-formaldehyde glue (such as EPI PVAc) production of the plate, the material must also be low with formaldehyde species. Can only meet the requirements of E0 sheet. But the domestic requirements and poor supervision, such a good PB (particleboard), MDF (medium density fiberboard), Veneer (plywood) is basically used for export. Domestic E0 you use pure wood it, this is the real E0 board.

- Q: What are the PCBs

- Flame Retardant Copper Foil Phenolic Paper Laminate. IPC4101 detailed specification number 02; Tg N / A;

- Q: Willow eucalyptus wood and pine which is good

- Many businessmen will use cheap wood eucalyptus, Malacca (another produced from Southeast Asia fast-growing cheap wood) core wood blockboard beautification into a "solid wood ecological board", attempt and solid wood detached, confuse, mislead consumers, but its essence Is still the use of cheap wood man-made sheet. The price is there. Pine, especially New Zealand pine widely used in the production of a variety of pine wood furniture, there are many specialized in the production of pine furniture brand, is also widely used in children's furniture and other fields. In addition, we must use a lot of glue and increase the risk of formaldehyde release. The plate will also increase the release of formaldehyde during the cutting process, and the same conditions do not have these problems. Of course, the use of blockboard can save a lot of cost, so for decoration, props production, especially public commercial space project is still very meaningful. So in general, a kind of wood is not dare to show his face, a large square is made of solid wood furniture wood. Combined with the actual value of the two woods in reality, and their application effects. Pine should be excellent and willow eucalyptus wood, Malacca.

- Q: Plate furniture formaldehyde release national standard is

- 0.08 bar. Furniture, what is more or less taste, so the distribution of formaldehyde will be more, this is also normal. Select the time to try to choose the sample, the placement of a long time there is no, or you can buy more time to smell, if you have bought back, put it, conditionally with some herbs to break down formaldehyde, Is no secondary pollution, no harm.

- Q: Malacca and the big board, fir board which is more suitable for the cabinet? Experienced to talk about it

- Currently on the market there is a board core for the fir Glulam, the surface of melamine finishes the board, the overall is also good, should gradually replace Malacca, the price is higher. Now we are talking about environmental protection, any kind of board are graded, there are good and bad. We can under the plate price, different levels of board price difference is quite large, and the other furniture production of the overall process and accessories for environmental protection will also have an impact, like the decorative plate furniture, edge technology, solid wood furniture, paint environmental Type, etc., when we buy the price is on the one hand, their actual needs and cost is king

- Q: Why is the PTFE sheet so slippery?

- In the plastic commonly known as "plastic king" of the PTFE plate, with excellent chemical resistance, corrosion resistance, aging resistance, self-sealing, non-stick, non-scaling and other excellent performance. Applicable equipment: the reactor, storage tanks, valves and containers lining, gaskets and so on.

- Q: What is the difference between a sunglasses or a sheet of plastic?

- Remove the sunglasses lens quality factors, the greatest impact on the price of sunglasses should be brand value-added and material caused by the different costs. Brand value added here is not discussed, this thing in the selection of sunglasses when the wise, can not tell a right and wrong. Then we talk about the material of the sunglasses frame. Compared to other materials, the use of sheet and plastic sunglasses frame on the surface is not see the difference. First of all, the plate frame is a memory function, if you buy the sunglasses mirror legs for you too tight or too loose, then you can adjust the mirror legs, straighten the bend is not a problem, but also inside and outside the bending Adjustment. If it is a plastic material sunglasses frame, a small adjustment does not work, it will automatically change back to the prototype, if a substantial adjustment - it will not change back to the prototype, because it has been broken ... Secondly, from the details, the frame of the frame to wear more comfortable, the basic will not appear discomfort. The plastic frame in addition to the overall structure is relatively stiff, is not conducive to the adjustment, the external paint may also be processed, there will be irritating smell. Finally, the frame of the frame will have steel (think of reinforced concrete, there are wood), durable. Plastic frame it, in addition to plastic or plastic, can be used to know how long days. So look at the appearance, you can not find the difference between these sunglasses.

- Q: Comparison of fire and water of the plate

- Solid wood is the best, the most upscale

- Q: Home decoration need to do wardrobe, what plate is the most environmentally friendly?

- Recommend you go to OKorder Long crystal, where the home decoration is very good, especially in the environmental awareness of today's popular people welcome!

- Q: What is cold rolled plate ah? Cold rolled plate is a plate of no

- Yes, the cold-rolled plate is a kind of plate, cold-rolled steel plate is a common carbon structural steel cold-rolled plate referred to, also known as cold-rolled plate, commonly known as cold plate, sometimes mistakenly written into cold rolling plate. For details, please contact the steel E station, where there are many cold-rolled plate introduction

Send your message to us

magnesium oxide board heat prevention material incorporated

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords