Supply magnesium oxide board,fireproof mgo board,magnesium board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Magnesium Oxide Board

Magnesium Oxide Fireproof Board (usually called magnesium oxide board) is the building

material widely used in the construction area. The stable magnesium colloid is reinforced by

middle alkali glass fiber net and stuffed by light material then becomes new frameless

decorative material. 100% no Asbestos Contained and no radioactivity.

Main Characteristic

1. Fireproof, non-combustible Class A1

2. Waterproof, moisture-proof, anti-corrosion, acid and alkali resistance

3. Heat insulation, and sound insulation.

4. Low shrinkage rate, light weight, and high strength, overall low density.

5. Smooth surface, can be painted, pasted tile, pasted wallpaper and other decorative materials.

6. Excellent fire resistance performance.Using 12mm thickness plate can be made

partition, it can reach 4 hours of fire resistance.

7. Construction cost of low, and can be cut, saw,nail,and bent.

Composition:

MGO Board is also called magnesium oxide board, fireproof board, magnesium board, magnesia board, mag board and so on. It is popular and warmly welcomed by clients from all over the world.

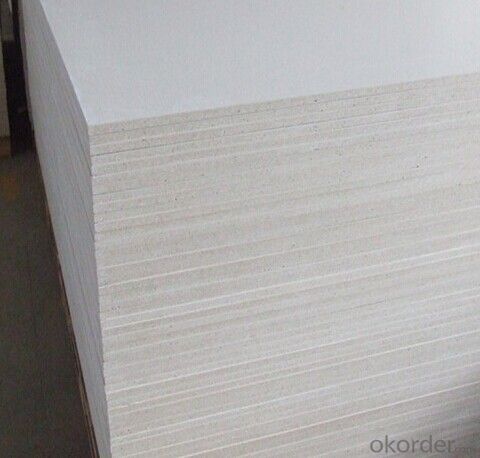

Raw Material: Magnesium oxide(MGO), magnesium chloride, perlite, Wood dust, fiberglass mesh, non-woven cloth etc.

Usage: Partition wall, fireproof, heat resistant

We have many years experiance in building materials fields and related machines, we know many core supplier very well and we also have our own factory for some of the building materials and machines, we are professional and honest to our customer, please inquiry if you have any questions and give us a chance to show our professional;

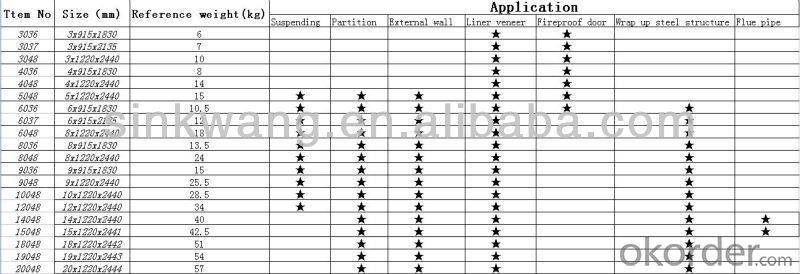

More details:

MGO fireproof sheet is a kind of environmental-friendly fireproof board widely used in construction and decoration. It's made from magnesium oxide, magnesium chloride, fiberglass mesh, sawdust, perlite etc. We use, highly-purified active MGO as the main fireproof material of board, high-quality MgCl2 as the main cementing material to solidify other materials, alkali-resistance fiberglass mesh to ensure the high strength of board, soft sawdust and light non-combustible perlite as filling materials.

MGO fireproof sheet enjoys strong points in more fields compared with the plasterboard and the traditional partition board, either in the decoration for modern construction or the fire resistent division for the industrial workshops

Features of the products :

1. Strong fireproofing capability: All the specifications of this product has reached the requirement of GB8624 fireproof level A and JC688-2006.

2. Good shockproof capability: This product is designed with many layers of high-strength fiber webs, which can effectively absorb part of the energy from the earthquake to avoid the instantaneous collapse of the isolation wall.

3. Smooth and scratchproof face: Advanced European and American production technology and recipes is introduced for this product, thus the turned-out board material is of smooth face and high hardness, collision and impacting will not result in depressions and scratches.

4. Good safety performance: This product is 100% free of asbestos and radiation, nor will it create the organic substance harmful to human bodies.

5. Superior performance in sound insulation and heat insulation: When used as the partition, this product can be filled inside to absorb sound, whose performance in sound insulation is better than the single brick wall meanwhile the cold and green house effect is raised, which saves energy and increases the economic benefit.

6. Damp-proof and non-reaction with halogen: The advanced and special production technology and recipes is introduced to cause the board material not to expand, peel off layer after layer, go moldy or react with the halogen like the plasterboard, silicic acid board or the common glassboard because of the damp environment, thus it can be widely used in the damper places such as bath-rooms, toilets and so on.

7. Wide applicable scope: Can be painted, jointed with wall-paper and sculpted or colored as the second processing.

8. Bend-proof: The structure of the board material is processed specially, thus the board material is flexible and elastic.

Applications:

- Q: The normal size of the solid wood board

- Long 243.84 cm wide 121.92 cm from the British standard 8 feet long 4 feet wide.

- Q: Bunny plate prices and Moganshan plate which is of good quality, expensive?

- The two almost, but I tend to king coconut plate, although he is also the top ten brands of plates, but the king coconut of the paint plate is the national standard drafting unit

- Q: What is the difference between steel sheet and coil?

- The plate is finished after the roll processing

- Q: Density board and Orson board difference

- MDF is made of wood and wood is not pressed by the degree of high temperature density is not Austrian loose board density

- Q: How to do the corn stalks

- Process Technology Line: 1. Straw density plate: Air dry straw → impurity removal → cut off → wind selection (blown out of the heart) → cans → high pressure steam → spray → fine → spray → drying → pavement → preload → hot pressing → edge → cutting → packaging → finished product 2. Straw crushed plate (particleboard) Drying Straw → Cutting → Wind Selection → Recovering → Drying → Screening → (Surface Layer, Dust, Core Material) → Mixing → Pavement → Preloading → Hot Press → Edge → Cutting → Inspection → Packaging 3. Straw composite board Straw → Cutting → Steam Blasting → Mixing → Paving → Wood Veneer → Glue → Preloading, Hot Press → Side → Varnish → Sanding → Finished 4. New wall materials: Corn stover high grain straw → election → leaves → cut → pavement → irrigation → do the surface layer → veneer → sanding → finished In addition to the above processing, the straw can also be used for pulp making after steam blasting, which is about a third less expensive than traditional pulping methods and only one third of the traditional method. It is helpful to solve the problem of pulp gap caused by the forced cessation of small papermaking by the state. Fourth, the main technical key and expected to achieve the technical and economic indicators: 1. Main technical key: ① developed as low as possible, environmentally friendly, waterproof superior, infiltration of a good name of the glue. ② design and improvement of grading pavement. ③ steam blasting equipment selection and the determination of the main process parameters. ④ hot pressing and cold pressing process parameters adjustment. 2. Expected technical and economic indicators: ① adhesive; solid content: 60% -65% ??????????Free formaldehyde content: 0.2% or less ??????????Viscosity: coated with 4 cups: 30 ℃ 10-20 seconds (fiberboard) ?????????????????????????????????50-65 seconds (particle board)

- Q: Which master please teach about aluminum alloy doors and windows under the material calculation method? Flattened; push-pull can be the best example. Thank you!

- General cut the formula is the total width of the outer frame minus 4 cm is equal to the extent of the frame up and down the slide; the total width of the shell minus 4 cents minus the two light business minus a hook enterprise divided by 2 equal to the upper and lower horizontal degree. This thing to find some information to learn. The The Find some content on the Internet about cutting down.

- Q: What is FR4 sheet

- FR-4 is a glass fiber epoxy resin CCL, a circuit board in the substrate, in fact, you should have seen, such as the kind of small game machine to open, inside the green board is FR-4 to do circuit board.

- Q: What is the sheet inside that?

- Do some of the board of the board is the board, solid wood. Be a very good plate. Again is the blockboard, the middle of the board, both sides posted deck, there is not how environmentally friendly particleboard. Density board. Chen goods of the furniture or office furniture, a little more.

- Q: How to degrease the wood

- Vacuum drying method The vacuum drying method is a method in which wood is piled up in a closed container and dried at a lower pressure than atmospheric pressure to remove part of the resin, and vacuum drying is suitable for wood having good air permeability. Vacuum drying method, can not achieve the desired effect. Vacuum drying is mainly characterized by drying faster than other methods, compared with other drying methods, drying time can be shortened about 25 ~ 1 2. Japan's Naito Truth [4] Drying of Douglas fir wood by high-frequency vacuum drying is considered to be effective for degreasing and mainly in the early stages of drying, since the moisture removal in the wood is in the early stages of drying, so its degreasing action is also in the early stages of drying. ] And other larch wood for cooking, vacuum and artificial drying, that cooking, vacuum degreasing effect is good, because the cooking to increase the permeability of wood.If the cooking, vacuum drying after artificial drying degreasing effect is better, because the vacuum drying Shorten the drying time.But the vacuum drying equipment is complex, the investment is high, there are vacuum drying machine manufacturers can use this method.To generally improve the degreasing effect, often using two or more degreasing method combination, such as Liquid immersion plus steam drying, pharmacy impregnation vacuum, steam vacuum pressure vacuum and other methods. The manufacturer can be based on the actual situation of the factory, choose the appropriate method for their own.

- Q: At present, in addition to solid wood, the most environmentally friendly sheet is E0 level?

- The current domestic plate to the EU standard as a certification standard, less than 0.5mg / L E0 level is the EU's highest standards. At present, there is no aldehyde grade sheet, formaldehyde content is less than 0.1mg / L, the test report is ND, no formaldehyde is detected, in fact, the instrument can not detect the corresponding value. Water-based science and technology to develop a strict standard days, the environmental requirements higher than the EU standards, is the most stringent home improvement, furniture materials product standards. Ke Tian established China's first home harmful chemical substances testing center, focusing on home improvement, furniture and other harmful chemicals, one-stop analysis and testing, can detect more than 100 kinds of harmful chemical substances.

Send your message to us

Supply magnesium oxide board,fireproof mgo board,magnesium board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords