Magnesium Alloy Plate AZ31B with Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Application of Magnesium Alloy Plate AZ31B with Low Price:

Sheet and plate in AZ31B find application in medium strength service at temperatures below 150°C. Diverse uses including aerospace, aircraft, concrete tools, 3C (cell phone / camera / computer), speaker cones and textile machinery can all benefit from light weight AZ31B.

2.Advantage of Magnesium Alloy Plate AZ31B with Low Price:

Superplastic forming of AZ31B sheet at elevated temperatures allows production of a wide variety of intricate parts for automotive uses. Monocoque construction utilizing formed sheet can be adapted to many commercial applications.

3.Mechanical Property of Magnesium Alloy Plate AZ31B with Low Price:

Table1 Squareness Tolerances

Ordered Thickness Inches | Allowable Difference in Length of Diagonals,Inches | |||||

Length Thru 18 Ins | Over 18 Thru 48 Ins | Over 48 Thru 120 Ins | Over 120 Thru 144 Ins | Over 144 Thru 180 Ins | Over 180 Thru 240 Ins | |

| 0.250-0.500 ...... | 3/8 | 3/8 | 3/8 | 3/8 | 7/16 | 9/16 |

| 0.501-1.00 ...... | 1/2 | 1/2 | 1/2 | 1/2 | 9/16 | 5/8 |

| 1.001-3.000 ...... | 5/8 | 5/8 | 5/8 | 5/8 | 3/4 | 3/4 |

| 3.001-3.500 ...... | 1 | 1 | 1 | 1 | 1 | 1 |

Table2 Flatness Tolerances

| Thickness, Inches | Deviation from Flat (Inches) | |

| In Any 1 Foot | In Any 6 Feet | |

| 0.250-1.000 ...... | 0.005 | 0.015 |

| 1.001-3.500 ...... | 0.010 | 0.020 |

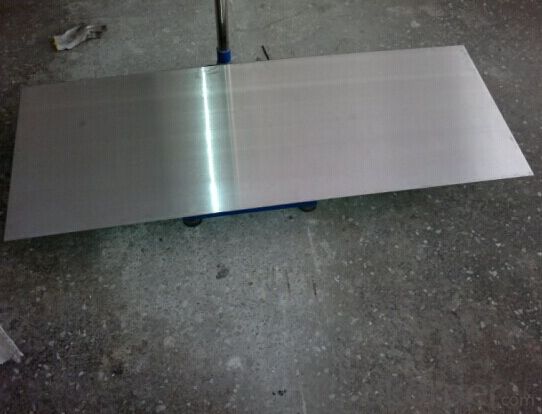

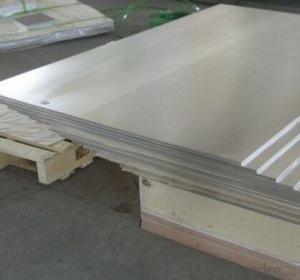

4.Picture of Magnesium Alloy Plate AZ31B with Low Price:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What is called cemented carbide?

- In addition to carbon atoms, a nitrogen atom and void boron atoms can enter the metal lattice, formed interstitial solid solution. With the properties of mesenchymal type carbide. They are similar to electrical and thermal conductivity, high melting point, high hardness, brittleness and is also large.The matrix of cemented carbide consists of two parts: one is a hardening phase, and the other is bonded metalIs the hardening phase transition metal carbides in the periodic table of elements, such as tungsten carbide, titanium carbide, tantalum carbide, their hardness is very high, the melting point of 2000 DEG C, and some even more than 4000 degrees. In addition, nitrides, borides, silicides of transition metals have similar characteristics, can also act as a hardening in hard alloy the phase hardening phase due to the existence of alloy with high hardness and wear resistance.Bonding metals are generally iron based metals, and cobalt and nickel are commonly usedManufacture of hard alloy, the size of raw powder in 1 ~ 2 microns, and high purity. Raw materials according to the provisions of the proportion of added alcohol or other medium in the wet ball mill in wet grinding, making them fully mixing, crushing, drying, sieving after adding wax or gel forming agent of a class then, after drying and sieving to prepare a mixture. Then, the mixture granulation, pressure type, heated to the melting point of the metal bond (1300 to 1500 DEG C) when hardening phase and bonding metal to form eutectic alloy. After cooling, the hardening phase distribution in grid bonded metal composition in each other closely together, form a firm whole. The hardness of the hard alloy depends on the hardening phase content and grain size, the hardening phase content is higher, more fine grain, hardness is greater. The toughness of cemented carbide by bonding metal bonded gold decision. The higher the content, the greater the flexural strength

- Q: Welding hard alloy cutter, hard alloy cutter, high speed steel, ceramic knife head head are what are the advantages and shortcomings?

- The advantages of carbide drill can drill more hard material, the disadvantage is to be good grinding, grinding is not good, easy to break the edge, two main cutting edge height and angle equivalent, it is best to use the grinding machine.

- Q: Hello, what's your company? What do you do with carbide? Thank you in advance

- Our company is the manufacturer of woodworking knives, made of carbide alloy circular saw blades and forming tools.

- Q: What is steel bonded carbide? What are its characteristics?

- Good physical and mechanical properties of steel bonded carbide in a hardened state has very high Hardness. Because it contains a lot of dispersed high hardness of hard phase, the wear resistance can be close to the high cobalt hard alloy. Compared with high alloy die steel, has high elastic modulus, wear resistance, compressive strength and flexural strength. Compared with the hard alloy, with good toughness. It has good chemical stability and self lubrication resistance, low friction coefficient and excellent.

- Q: Carbide saw blades, plain and alternating teeth. What do you mean? That good?

- .1., about the most widely used teeth, cutting speed, grinding relatively simple. Suitable for cutting and crosscut various soft and hard wood materials and MDF, plywood, particleboard etc.. Equipped with anti elastic protection around the tooth is tooth plate for dovetail, longitudinal cutting of various degree; with negative rake angle of tooth saw blade sharp, serrated cutting because of good quality, usually used for veneer cutting.2. flat tooth saw is rough, cutting speed is slow, grinding is the most simple. Mainly used for sawing ordinary wood, the cost is lower, more used for smaller diameter aluminum saw blade, in order to maintain cutting to reduce adhesion, or used for grooving saw blade, to keep the groove bottom leveling.

- Q: Carbide coated drill bit. Do you have one there?

- 1. carbide drills are generally worn in the back. Then it has little influence on service life.2., the high strength of the workpiece material, easy to cause the front of the drill (spiral groove) wear, bit life impact.

- Q: The milling of hard cutting workpiece hard alloy cutter knife edge collapse and Countermeasures of reason

- The cutter model is wrong, the milling can not move the material, the resistance is big, then the knife breaks. Use 75 degrees to make the plane

- Q: What is the difference between the production process of ferrous powder metallurgy and cemented carbide?

- After the Second World War, the rapid development of powder metallurgy technology, new production technology and technical equipment, new materials and products continue to emerge, develop some special materials manufacturing field, has become an important part in modern industry.

- Q: Can YG813 carbide cutters be used for cutting stainless steel intermittently? How much is the cutting speed?

- YG type alloy has good impact resistance, can be used to cut stainless steel, cutting speed 80m/min, heightening the concentration of emulsion about 8%, of course, if there is YW alloy better, wear-resistant, heat hardness and hardness are higher

- Q: What are the differences in performance between cemented carbide cutting tools and PCD cutters (polycrystalline diamond)?

- PCD has a very high hardness, but its toughness is not as good as carbide, much lower than high-speed steel, therefore, the main failure form of PCD cutting tool is cutting edge.PCD cutters can effectively process non-ferrous metal materials and non-metallic materials. Such as copper, tungsten and other non-ferrous metals and their alloys, ceramics, hard alloy, various fiber and particle reinforced composite materials, plastics, rubber, graphite, glass and wood, but the diamond is not suitable for cutting steel and other iron materials.

Send your message to us

Magnesium Alloy Plate AZ31B with Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords