Magnesium Alloy Plate AZ31 AZ31b AZ61High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Application of Magnesium Alloy Plate AZ31 AZ31b AZ61High Quality :

- Aerospace, defense and satellite applications where weight reduction is critical

- Electronic components where shock absorbing qualities are crucial

- Automotive/Motor sports applications where weight reduction and strength are required

- Mechanical vibration shakers for test fixtures

2.Advantage of Magnesium Alloy Plate AZ31 AZ31b AZ61High Quality :

- Magnesium is the lightest industrial metal in the world

- One third lighter than aluminum

- Magnesium is as strong as aluminum

- Magnesium is shock absorbing and dampens vibrations

- Magnesium is very machinable

3.Mechanical Property of Magnesium Alloy Plate AZ31 AZ31b AZ61High Quality :

Magnesium Alloy | |||||||||||

Type | Chemical element (%) | ||||||||||

Mg

| Al

| Zn

| Mn

| Si

| Fe

| Cu

| Ni

| Be

| Other Metallic impurities Max each | Other impurities Max

| |

AZ91D | Balance | 8.5--9.5 | 0.45-- 0.9 | 0.27-- 0.40 | 0.08 max | 0.004 | 0.025 | 0.001 | 0.0005- 0.0015 | 0.01 | --------- |

AM60B | Balance | 5.6--6.4 | 0.20 max | 0.26-- 0.50 | 0.08 max | 0.004 | 0.008 | 0.001 | 0.0005- 0.0015 | 0.01 | --------- |

AM50A | Balance | 4.5--5.3 | 0.20 max | 0.28-- 0.50 | 0.08 max | 0.004 | 0.008 | 0.001 | 0.0005- 0.0015 | 0.01 | --------- |

AZ63A | Balance | 5.5--6.5 | 0.27-- 3.3 | 0.15-- 0.35 | 0.20 | 0.00035 | 0.20 | 0.010 | 0.01 | ------- | --------- |

AS41B | Balance | 3.7--4.8 | 0.10 max | 0.36-- 0.6 | 0.60-- 1.4 | 0.00035 | 0.015 | 0.001 | 0.0005- 0.0015 | 0.01 | ---------- |

AZ91A | Balance | 8.5--9.5 | 0.45- 0.9 | 0.15-- 0.40 | 0.20 max | ------ | 0.08 | 0.01 | ------- | -------- | ----------- |

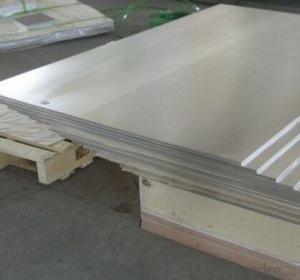

4.Picture of Magnesium Alloy Plate AZ31 AZ31b AZ61High Quality:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What is hard alloy steel?

- Modern ultra hard alloys are produced by sintering of carbides of tungsten carbide and some other elements. It is the hard metal (tungsten, tantalum, titanium, molybdenum, etc.) carbide carbide particles, with one or several iron elements (cobalt, nickel or iron) powder mixed, pressed molding, and then made by sintering.

- Q: One can write on the hard alloy on the pencil, what's the name ah, who knows.

- What pen is this?Chasing the answer230 yuan each. You can contact me any time you like.

- Q: Japan steel tungsten carbide which is good

- Japan steel tungsten carbide recommended Kunshan aloi precision mould Co. Ltd, Japan Istanbul technology research of copper tungsten alloy used for professional sales of Japanese steel tungsten carbide and discharge EDM, silver tungsten alloy, copper alloy; discharge EDM tungsten copper, copper thread electrode; non-standard thread electrode, thread grinding machining

- Q: What are the parameters of the wear resistance of cemented carbides in addition to their hardness?

- The wear resistance of cemented carbide is related to the proportion of titanium carbide and cobalt carbide contained in it. It contains more titanium carbide, less cobalt content, higher hardness and better wear resistance. But brittleness also increases, easy to break the edge, so it is suitable for finishing.

- Q: We'll drill on the stainless steel column. Which bit is better?

- High cutting force and high cutting temperatureThis kind of material has high strength, large tangential stress and large plastic deformation during cutting, so it has great cutting force. In addition, the material has a poor thermal conductivity, which results in the increase of cutting temperature, and the high temperature often concentrates in the long and narrow area near the cutting edge of the tool, thus speeding up the tool wear.Serious work hardeningAustenitic stainless steel and some high alloy stainless steel is austenite, high work hardening tendency when cutting, usually plain carbon steel several times, the tool in hardening region cutting, shortening tool life.Easy to stick the knifeBoth austenitic stainless steel and martensitic stainless steel exist in the process of chip toughness, cutting temperature is very high. When the tough chip flows through the rake face, the bonding, welding and other sticking phenomena will occur, which will affect the surface roughness of the machined parts. ??Tool wear acceleratedThe materials generally contain high melting point elements, large plasticity, high cutting temperature, so that the tool wear faster, sharpening and changing knives frequently, thus affecting the production efficiency and improving the tool cost.Mainly to reduce the cutting line speed, feed. With special processing stainless steel or high temperature alloy cutting tools, drilling, tapping the best internal cooling

- Q: Can ceramic tools process cemented carbides?

- No, ceramic cutters are usually used to process cast iron (high speed machining) and high hardness steel (Cui Huogang).Generally, the hardness of ceramic tools reaches HRA91-95, while the hard alloy can reach HRA93.The main components of ceramic tool materials are Al2O3 with high hardness and melting point. Si3N4 and other oxides and nitrides, and then added a small amount of metal carbide, oxide or pure metal additives, formed by pressing, sintering, and then a tool material. Its hardness can reach HRA91 ~ 95, and the hardness of HRA80 can still be kept at the cutting temperature of 1200 DEG C. In addition, the chemical inertia is large, the friction coefficient is small, and the wear resistance is good, and the service life of the processed steel pieces is 10~12 times of that of the hard alloy.Its major disadvantages are brittleness, low bending strength and low impact toughness. Therefore, it is mainly used for semi finishing and finishing, high hardness, high strength steel and chilled cast iron and other materials. Commonly used ceramic cutting tools are alumina ceramics, composite alumina ceramics and composite silica ceramics.Taiwan is hard gold metal carbide with high heat resistance and high wear resistance (WC tungsten carbide, titanium carbide, tantalum niobium carbide TiC TaC, NbC etc.) and metal binder (cobalt, nickel and molybdenum) powder metallurgy products under high temperature sintering. The hardness of HRA8 9 ~ 93, 850 ~ 1000 DEG C high temperature resistant, has good abrasion resistance, allowing the use of the cutting speed can reach 100 ~ 300m / min, can be a variety of materials including machining hardened steel, therefore it is widely available.

- Q: The milling of hard cutting workpiece hard alloy cutter knife edge collapse and Countermeasures of reason

- The cutter model is wrong, the milling can not move the material, the resistance is big, then the knife breaks. Use 75 degrees to make the plane

- Q: How are cemented carbides sintered?

- After cooling, the hardened phases are distributed in a grid of bonded metals that are closely related to each other and form a solid whole. The hardness of cemented carbide depends on the content of the hardened phase and grain size. The higher the content of the hardened phase and the finer the grain, the greater the hardness. The toughness of cemented carbide is determined by bonding metal. The higher the bonding metal content is, the greater the bending strength is.

- Q: Import all carbide drill bit, mainly those brands

- Domestic is so cheap, why use foreign diamond brand is very good?

- Q: Printing requirements for cemented carbide

- Because of its superior properties such as high strength, hardness, excellent wear resistance and oxidation resistance, carbide is widely used in mechanical processing, petroleum mining, mold forming and structural wear-resistant parts and other fields. In the production of cemented carbide, sintering is the most important process. Even if the compacts are the same, different sintering processes have different effects on the properties of the sintered products. For a long time, many researchers have gradually formed a variety of sintering methods in actual production, including vacuum sintering, hot isostatic pressing sintering, vacuum follow-up hot isostatic pressing, sintering, hot isostatic pressing, etc..

Send your message to us

Magnesium Alloy Plate AZ31 AZ31b AZ61High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords