Low Price Baggage winding machine made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

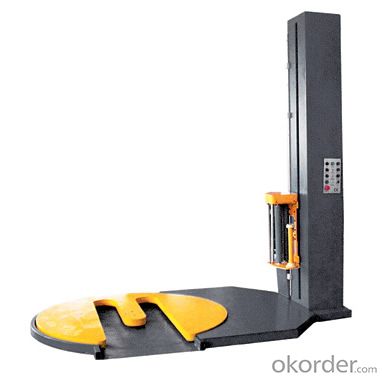

Low Price Baggage winding machine made in China

Description of Low Price Baggage winding machine made in China

The airport baggage wrapping machine is designed for airport packing luggage. It can prevent baggage from being damaged and exchanged, which protects the baggage during transportation. The equipment can be moved and the equipment is automatically packed. The general luggage bag (3 to 5) layers can be used! After packaging, the operator manually cuts the film and removes the luggage! The luggage packed by the luggage wrapping machine is safe, beautiful, and tidy, effectively solving the inconvenience of the traffic department and passengers.

Main Features of Low Price Baggage winding machine made in China

1, Program-controlled unit machine

2, Sutomatically sense the height of the goods

3, Reinforcement winding function, can be a special part of the protection

4, Turntable frequency modulation 0~12rpm adjustable;

5, Inverter parameter download function, easy to restore the factory settings.

6. Integral rotary sprocket, star six-wheel auxiliary support, turntable automatic reset

7, Equipped with a forklift slot at the bottom of the turntable

8. Membrane pre-tensioning mechanism, pre-stretch up to 250%; automatic diagnosis and suspension processing when the membrane is broken

9, Double chain drive structure, stable and reliable

10, Membrane frame rise, fall, film feeding speed can be adjusted;

11. The top and bottom winding numbers are separately controlled;

12, Film system follow-up agencies, a pull can be;

13, User-friendly intelligent parameter settings, the operation is more simple and convenient

14, Interface display can be set directly, the control panel clean and beautiful

15. Man-machine dialogue is realized, and the display screen shows the operation of the equipment at any time

16, Using integrated communication, frequency conversion speed is more significant;

17. Digitally set the starting point and the end point of package height freely, and realize flexible packaging methods

18, Fewer wiring control methods, the failure rate is reduced to a minimum

19, Powerful fault diagnosis and pause processing function

Specifications of Low Price Baggage winding machine made in China

| Power supply | 1P AC220V 50HZ 1KW |

| Turntable speed | 0-20r/min |

| Film stretching device | Film tension unit can be adjusted Frequency adjustment (pre-stretch) |

| Package weight | The maximum package weight 60kg |

| Effective package size | L(250-1200)xW(200-400)xH(250-1200)mm |

| Machine size | L1600xW600xH1740mm |

| Machine weight | 150kg |

| Noise | ≤75DB |

| Surroundings | Humidity ≤98%, temperature 10°C~40°C |

| Lubricant materials | General purpose grease lubrication material |

Applications of Low Price Baggage winding machine made in China

The airport baggage wrapping machine is designed for airport packing luggage. Therefore, it plays a role of protection during baggage transportation to prevent damage. Prevent baggage from being exchanged! The operator puts the baggage on the turntable and adjusts the vertical bar according to the size of the baggage so that the baggage can be placed on the turntable smoothly. Then the operator presses the start button on the operation panel, and the equipment is automatically packaged. The general luggage bag can be 3 to 5 layers! After packaging, the operator manually cuts the film and removes the luggage.

Images of Low Price Baggage winding machine made in China

FAQ

Q1. Does your machine fit for different volumes?

A: Yes, one machine can fill different volumes, which is based on your product information.

Q2. Can your machine reach different production?

A: Yeah, we can make machines with different of filling nozzles, and the nozzle numbers based on your production. You can adjust different filling speed within the range.

- Q: Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- If you have your own website here, through the optimization and promotion, to promote their products out, the customer concern, love content search, when people search through GG to see your home site, you may consult. There are many ways

- Q: What are the main functions of packaging machinery?

- In order to meet the requirements of many customers, our company has learned from all aspects of the role of packaging machinery and equipment, so that we need customers for reference

- Q: Color code positioning of packaging machinery

- The main products are: packaging machinery series of quantitative packing machine, vacuum packaging machine, packing machine, strapping machine, sealing machine, bag machine, carton forming machine, packing machine, winding machine, labeling machine, stacking machine, and the design of various transmission lines; at the same time, the production and sale of packing tape, stretch film and other packaging material.

- Q: What's the best place to use the pillow type packing machine?

- In the early communication can be reflected, and sometimes non-standard customized to see the level of Technology

- Q: What is the name of the paper used in packing machine parts and yellow?

- Rust preventive action, commonly used for steel vapor rust preventive paper, but also for a variety of metals.

- Q: Food packaging process is not standardized, there is no responsibility?! For example, after the production of candy, because there is no corresponding packaging equipment, the need for artificial packaging

- You can send me a picture of your product and the process, so that I can answer your question exactly. More than 70% of the candies on the market are now automatically packed.

- Q: What is a packaging machine?

- Packaging machinery refers to the machinery that can complete all or part of the product and commodity packaging process. The packaging process includes filling, wrapping, sealing and other main processes

- Q: Energy saving reform of packaging machine

- A) the main control circuit is composed of man-machine interface (text display), frequency converter and programmable logic controller (PLC), which constitute the control core;B) the temperature control circuit is composed of an intelligent temperature control meter, a solid state relay and a thermocouple element. The temperature control is accurate, the display is intuitive, and the setting is convenient;C) multi point tracking and detection by photoelectric switches and electromagnetic proximity sensors; 2) fully automatic pillow type working principle:With the improvement of automation, the operation, maintenance and routine maintenance of the packing machine are more convenient and simple, and the professional skill requirements of the operators are reduced. The quality of the product packaging is directly related to the temperature system, the speed accuracy of the main engine and the stability of the tracking system.

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- This standard specifies the terms and definitions, models, types and basic parameters, technical requirements, test methods, inspection rules and signs, packaging, transportation and storage requirements of the three-dimensional packaging machine for transparent film.

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- Mechanical sales are nothing more than two points: first, equipment aging, need to update; two, equipment efficiency is low, need to improve. You don't know anything about the customer. Come up and sell the product. If you are a customer, I don't think you have the patience to listen

Send your message to us

Low Price Baggage winding machine made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords