Low Price Automatic conveyor made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Low Price Automatic conveyor made in China

Description of Low Price Automatic conveyor made in China

The roller dragging the work plane transmission movement is used to achieve the purpose of the production process. The assembly line assembly mode is adopted in the assembly line, and the number of stations and the distance between the rollers can be set according to the process requirements.

Main Features of Low Price Automatic conveyor made in China

Structural form:From the driving form, there are power, no power, and electric roller. According to the layout, it is divided into horizontal conveying, inclined conveying and turning conveying.

Size specifications:The width of the roller conveyor is specified by the customer and can be made according to customer's requirements. The standard turning inner radius of turning roller line is 300, 600, 900, 1200mm, etc. Other special specifications can also be used according to customer's requirements. The drum diameter used in the straight section drum is 38, 50, 60, 76, 89mm and so on. The taper of the turning drum is designed based on the weight, size, and line speed of the conveyed object.

Rack material:carbon steel spray, stainless steel, aluminum profiles.

Power mode: gear motor drive, electric roller drive and other forms.

Transmission mode: single sprocket, double sprocket, O-belt, plane friction transmission belt, timing belt and so on.

Speed control method: frequency control, stepless speed change, etc.

Equipment characteristics: easy to connect between the drum line filter, can use a number of roller lines and other conveyor equipment or special machine to form a complex logistics delivery system and diversion confluence system, to complete a variety of process needs. Accumulation drum can be used to achieve the accumulation of materials. Roller line structure is simple, high reliability, easy to use and maintenance, power roller line considering the tensile strength of the chain, the longest single line length generally does not exceed 10 meters.

Specifications of Low Price Automatic conveyor made in China

| Line length | According to customer's process needs |

| Line width | According to customer's process needs |

| Roller spacing | According to customer's process needs |

| Face width | 750±25mm (selected value) |

| Recommended speed | Mechanical fixed type, electromagnetic control type, frequency conversion type |

| Operation mode | Continuous, beat |

| Scope of application | Electromechanical, home appliance product assembly, transportation, packaging |

Structure type:According to the driving mode, it can be divided into power roller line and non-power roller line, and can be divided into horizontal conveying roller line, inclined conveying roller line and turning roller line according to the arrangement form. Can also be specially designed according to customer requirements to meet the requirements of various types of customers. The standard gauge drum line width is 200, 300, 400, 500, 1200mm and so on. Other special specifications can also be used according to customer requirements. The standard turning inner radius of the turning drum line is 600, 900, 1200mm, etc. Other special specifications can also be used according to customer requirements. The drum diameter used in the straight section drum is 38, 50, 60, 76, 89mm and so on.

Applications of Low Price Automatic conveyor made in China

For mineral water, juice, beverage, liquor, beer, infusion bottles and other product development, speciality, stable performance, product packaging, fastening, beautiful.

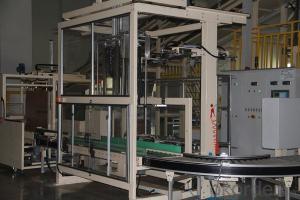

Images of Low Price Automatic conveyor made in China

FAQ

Q1. Does your machine fit for different volumes?

A: Yes, one machine can fill different volumes, which is based on your product information.

Q2. Can your machine reach different production?

A: Yeah, we can make machines with different of filling nozzles, and the nozzle numbers based on your production. You can adjust different filling speed within the range.

- Q: What is the general packing cost of beer beverage packaging?

- A privately owned enterprise production and processing, wholesale distribution, production of various types of complete packing machine, sealing machine, packing machine, vacuum machine, sealing machine, electromagnetic machine, packing machine, mushrooms should be material, full automatic filling machine, cuff type packing machine, sending spot

- Q: Vacuum packing machine for cooked food: can whole chicken, whole goose and whole duck be packed?

- Well, yesBut the vacuum packaging machines used for different product sizes are different

- Q: Predecessors please point out: what is the future of packaging machinery industry?

- Hello, in recent years, Chinese packaging industry, although the annual growth rate ranked in the traditional industry for the first time, but in line with the international market, to accelerate the development of packaging technology, make its development to the economic, efficient, multi-functional direction. According to the development plan of Chinese national economy and to realize well-off life level, this year a few years for the packaging industry, the food industry to provide equipment for 100 billion yuan to 200 billion yuan, 80 billion yuan to 100 billion yuan to provide equipment for the "vegetable basket", this is a good opportunity for development of enterprises. At the same time, I learned from the relevant ministries, "95" period, will invest 10 billion yuan in the packaging industry to support and transform large and medium-sized packaging enterprises.

- Q: What are the main plastic forming processes?

- Plastic processing is a complex process, generally divided into the following processing methods:In order to improve the quality of the product and improve the molding efficiency, the pre pressing is used to press the powder or fibrous molding material into a certain shape in advance.Preheating, in order to improve the processing performance and shorten the molding cycle of molding plastics, the molding plastics are heated prior to molding.Molding in the mold to add the required amount of plastic, closed mold and exhaust, at the mold temperature and pressure to maintain a period of time, and then release mold cleaning operations

- Q: What are the packing machines?

- Glass glue category of automatic and manual soft packing machine, chemical, I do not know what you are talking about? You can go and have a look.

- Q: Working principle of packing machine

- In the first step, the wrapping paper is pulled down by a bag pulling motor, and then the paper part is supplied with paper according to the signal of the paper feeding sensor, and the wrapping paper is formed through the forming part of the shaper

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packaging machine packaging production, simple operation and high degree of automation, high efficiency, low packing cost, save labor, reduce the damage and the characteristics of two pollution, by tableware shrink packaging is widely used in all kinds of, is a very mature model

- Q: How is the production and characteristics of ceramic wall tiles different from the size and performance of molding?

- What is the size of the parison forming pressure and the performance of the ceramic wall and floor tile products?Ceramic wall and floor tiles are usually formed by pressing. Domestic made for 30 tons, imported equipment has tons of suppression, 200 tons and 500 tons. In order to smooth accurate size, excellent products, must pay attention to the effect of powder properties and compression of products. That is to say, the quality of the floor tiles, billets, methods of preparation, and the quality of products and production scale and way of pressing machinery. As for pressing pressure, as the molding pressure decreases, the sintering shrinkage becomes smaller and the water absorption rate becomes smaller, the durability of the product should be improved. It should be noted that the pressure should not be too high. Excessive pressure, stress, and density increase will cause unnecessary energy consumption, and cause compressed air to expand after pressure is canceled and cause excessive spalling.

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Now the standard of living has improved, basically the vacuum bag. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- Ha ha, as you say, TV factories are closed down, every household has a TV, but every day there will be a lot of people buy tv.

Send your message to us

Low Price Automatic conveyor made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords