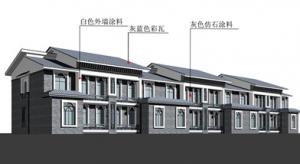

Light Steel Villa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000㎡ m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

This product belongs to Ligth Steel Frame Structure.

This structure is formed by the dense light steel studs and compound envelop and with all kinds of supprior physical qualities.

Advantages:

1. Flexible combination

2. Easy transportation

3. Fast construction

4. Cost saving

5. Removable & recycle

6. Thermal Insulation

7. Seismic and wind resistance

8. Roof Load-bearing

Packing:

light steel packing: light gauge steel in bulk, decorate panel material in pallet, other fittings all in boxes, loaded into 40' GP and 20' GP on container.

- Q: Volkswagen Lanyi door did not lock the hole no electricity how to do

- Hello, it is recommended to drag the repair shop or 4s shop, the roof up and then the lower shield removed, with a wrench or hook can be hooked to the cover pull, pull the lid (looking for a battery) to the battery head Can be removed on the up, the car has a problem, ask the car master. 4S shop professional technician, 10 minutes to solve. To

- Q: I need to replace the black thing that you push the buttons on to open the door and trunck. I replaced the battery and it still doesnt work where do I find a new one??

- Ask for the programming instructions just in case.

- Q: How does steel frame formwork contribute to the overall sound insulation of a concrete structure?

- Steel frame formwork does not directly contribute to the sound insulation of a concrete structure. The primary purpose of steel frame formwork is to provide support and shape to the fresh concrete during the construction process. The sound insulation of a concrete structure is typically determined by other factors such as the thickness and density of the concrete, the presence of insulation materials, and the sealing of any gaps or joints.

- Q: Composite foam cement insulation board, composite foam insulation board What is the level of fire insulation materials?

- Class A. Poor thermal conductivity

- Q: I have a very outdated bathroom with pink tile covering just about every wall. I love to do DIY projects but can‘t afford to replace the tile. I can however afford to paint it. I read up on it and found the paint directions but don‘t want the end result to look tacky. Has anyone done this and liked the results?

- have seen it after was completed came up reasonable you have to clean the tiles then apply a special primer then the tile paint there are pens around that can redo the grout lines. you must get the correct materials and follow everything as recomended the paints are not cheap. they might not have those paints in the. U.S.

- Q: How do geomembranes contribute to the preservation of water resources?

- Geomembranes contribute to the preservation of water resources by providing an effective barrier that helps prevent contamination, leakage, and seepage of liquids, thus safeguarding water quality. They are widely used in various applications such as lining of reservoirs, ponds, and landfills, as well as in wastewater treatment facilities, ensuring the protection and conservation of valuable water supplies.

- Q: Can steel tube couplers be used for temporary access or support structures outside of scaffolding?

- Certainly, steel tube couplers can be utilized for temporary access or support structures outdoors, apart from scaffolding. They find extensive usage in various construction and engineering projects that necessitate a temporary structure. Steel tube couplers facilitate a robust and secure connection between steel tubes, enabling the creation of sturdy and dependable structures. They are commonly employed in applications such as temporary walkways, bridges, platforms, and supports. These couplers possess versatility and can be easily assembled and disassembled, making them well-suited for temporary structures. Moreover, steel tube couplers are specifically designed to endure substantial loads and adverse weather conditions, ensuring the safety and stability of the temporary structure.

- Q: How is the bathroom too small?

- Use the corner frame bathroom space can be used to use corner space to install the corner of the rack or wall nail triangular laminates board using bathroom supplies, cleaning supplies, changing clothes ... ... layer placed easy to solve the space in the narrow problem to remind the bathroom space Placed in the wet bathroom board or shelves wooden or iron frame by the moisture-proof treatment or use more pressure-prone material bar

- Q: I live in a condo, and ive notived theres some kind of pvc piping slightly protruding from above the ceiling in the shower. this pipe occasionaly drips water. not alot, but definitly enough for me to see it and hear it, and take notice. Is this a problem with the above neighbors living above me? what exactly is the purpose of that piping? sorry for the vague description, but i dont know how else to describe it. help is appreciated.

- 1. you should not see exposed pvc pipe in your condo. If you own the condo, I would report this to the association. 2. The leak could be sweat from the pipe, not likely though. 3. It would hard to fix because right now you haven't a clue who the pipe belongs to.

- Q: What is the quality of b grade laminate flooring? Does it scratch if a piece of paper touches it?

- While not specific to laminate flooring, grade 'b' flooring in general is a step down from the top of the line, generally exhibits subtle flaws on the surface but maintains an even coating surface (that is to say, you don't have to fill extra space). With most hardwoods this translates to a rating of #1 or #2 common floors. With Laminate floors I would guess that there would be mild warping, and slight unevenness in the surface. Perhaps a lower quality laminate used, but mostly a lower grade particle board backing, which would lend itself to being cracked along the seems easier.

Send your message to us

Light Steel Villa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000㎡ m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords