large roof wall color steel composite and modified phenolic fireproofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

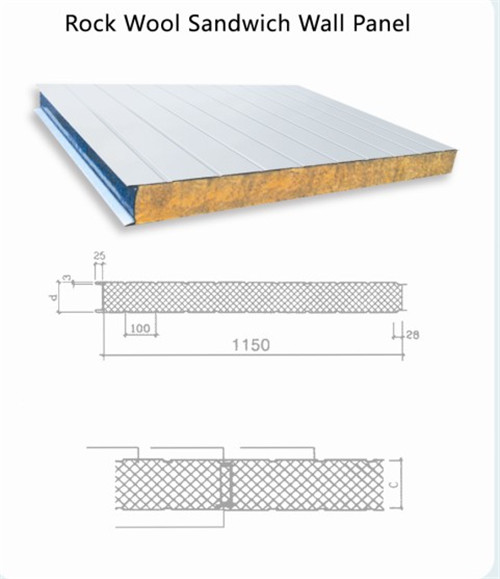

| Place of Origin: | Hebei China (Mainland) | Brand Name: | wzh | Model Number: | 950/1150mm for wall or ceiling or 950mm as roof |

| Panel Material: | Metal | Type: | Rock Wool Sandwich Panels | Thickness: | 50/75/100/125/150/200 mm |

| Color: | Many color are available, but white grey, sea blue and bright red | Materials: | Rockwool, EPS, PU sandwich and two sides are oosteel sheet | Certification: | ISO9001&ISO14001 |

| Name: | sandwich panel; coposite panel;steel plastic composite pannel | Length: | as your require | Effective width: | 950/1150mm for wall or ceiling or 950mm as roof |

| Utilisation: | prefabricated house, container house,cold room | Kinds: | roof panels; wall panels | Charastic: | heat perservation; waterproof |

Packaging & Delivery

| Packaging Detail: | standard export pallet,with protective corner guard and film on the four sides |

| Delivery Detail: | 15 days after recieved despoit |

Specifications

EPS composite board rockwood composite board glassfiber composite board

Light weight

High intensity Sound proof Easy installat

EPS composite board rockwood composite board glassfiber composite board

The usual sandwich panels include rock wool Sandwich panel, EPS sandwich panels, PU Sandwich Panel, glass fiber sandwich pannels. The up & down surface of this panel is Galvanized & Prepainted steel sheets, core material is rock rood, EPS, PU, and glass fiber. It is formed by heating, foaming & laminating. It is the best material for temperature keeping and sound insulation. It is widely used as the wall or roof for cold storage, industrial workshop, public building etc.

Specifications

(1)Core Material: Rock Wool, EPS, PU; Surface Materials: Galvanized Steel sheets or Prepainted Steel sheets.

(2)Wall Thickness: 40, 50, 60, 80,100,120,150,180,200,250mm

(3)Max. Width: 1200mm

(4)Length: according to client's demands, engineering requirements and shipment conditions

(5) Application: for ceiling & wall, partition wall

(6) Widely used in common steel structure and storey adding projects,e.g. adding storey to small steel structure industrid factory building worehouse,suburbon temporary office,residentid quarters,school,hospital,etc.

Characteristics

1) With a light weight, a giraffe fitting and random incise characteristic, the fitting is much simpler, and it can advance the benefit and save the time limit for a project

2) Color coated sandwich panel's surface material and heat preservation material are non-burn or hard-burn materials, entirely satisfy the fireproofing criterion request

3) Manifold disquisition and oversea used approving more than 40 years. By especial coated dispose, the color coated steel panel's guaranty is 10-15 years, and the panel's life express 35 years by painting the antisepsis material after each 10 years

4) Pressing steel panel with the clear line, and many colors for choice, and suit with any different building style materials, achieving the satisfying effects.

5) In common use heat preservation materials are rock-wool, polystyrene,

polyurethane, all with lower thermal conductivity and favorable heat preservation and heat insulation effects

6) Sound insulation intension can be 40-50dB, it is the most effective sound insulation material

7) Pressing steel panel can be arbitrariness incise, it can satisty the especially design demands

8) Use the high strength steel panel for the base metal (contradict open and pull intension 5,600kg/cm2), adding the most advanced design and roll pressing moulding, it gets the best structure character

9) Improves speediness and springiness designs according to clients' requirements.

- Q: I see the tutorial, in Altium, click the design under the layer stack manager, pop-up layer stack manager, double-click the top layer or core or bottom layer can set some parameters, those parameters can not be set?

- This is not set up, only in the proofing requirements. In addition, pcb industry also has line specifications. Usually the board does not have special requirements will do 0.35um.

- Q: F grade sheet and EO-class plate, what is the difference between these two, Guiqiu master answer, buy a furniture to the market a question, really a headache? Which is good?

- In general, if you export to Japan, you must provide F4 star certification. And E0 is our national standard (methanol content ≤ 5mg / 100g). F4 star standard is much higher than the E0 standard.

- Q: Many cabinet manufacturers will use their own plate labeled as "the whole board", the Internet can not find the whole plate in the end what is the essence. I would like to ask you, the whole board is what board?

- Cabinet with the overall plate is the compression plate.

- Q: Does the regular FR4 sheet contain halogen?

- Very likely to contain halogen, but there is a standard, as long as no more than the minimum standards can also meet the European environmental standards.

- Q: With self-tapping or what ,,,, solve, six meters wide and two meters of the door can be installed on the ground in the installation of the door?

- Are generally used self-tapping nails, if relatively heavy or relatively large load, you can use bolts. Aluminum-plastic composite board is a chemically treated coated aluminum sheet for the surface material, with polyethylene plastic as the core material, in the special aluminum-plastic plate production equipment from the processing of composite materials. The unique performance of the aluminum-plastic composite panel itself determines its wide range of uses: it can be used for building facades, curtain wall panels, retrofits of old buildings, interior walls and ceilings, advertising signs, display stands, engineering. Belonging to a new type of building decoration materials.

- Q: Three thousand square plate is good?

- I think you still have to believe that a sub-quality goods, choose the plate, can not just look at the price, but also depends on the quality, reliable quality and stability to deal with home decoration. So I can only say that the home decoration or the need for an environmentally friendly space so I think the election three thousand square or value for money, specifically to see your needs!

- Q: Home decoration do want to do the solid wood doors and cabinets, but also the package side of the package, but it is said that easy to deformation if the use of solid wood inside the panel with solid wood panels, then it will stick with environmental performance as solid wood, but not easy to deform it to see the market with pine materials A lot of everyone is what advice next week on the woodworking undecided ah.

- Do not know you forget no, you go back to buy the material to ask the master to do the door, even the work with the material and you buy the door outside the price are basically the same, but their own door quality can be better, and Made the door is nice, some pattern carpenter he can not do it! Anyway, you choose it yourself. I can only give you a reference, so I am a good decoration, and time to my house to see.

- Q: How much does the ring do the ring?

- Do ten ring certification is mainly to see if you are doing a type of ten rings or two rings, if you do here for the purpose of ten rounds of tender, it is recommended that you can do a type of ring certification. You need to do the EIA, but also to prepare the early data. I was in OKorder million Germany to do the ten ring certification, then in order to bid, so do anxious, a month to get the card

- Q: E0.E1 level is the level of formaldehyde content, the specific number is how much

- The E0 grade of the sheet is the concept of formaldehyde emission limitation in the new national standard GB / T9846.1-9846.8-2004. The standard divides the formaldehyde limit level into three levels, namely: E1 level free formaldehyde release limit ≤5.0mg / L </ FONT> (meet the domestic standard), E1 free formaldehyde release limit ≤ 1.5 mg / L </ FONT> (in line with European standards), E0 level free formaldehyde release limit ≤ 0.5 Mg / L </ FONT> (the world's top standard). ???? E0 grade plate although the environmental standards are higher, but because it does not contain green moisture-proof agent and adhesive, its toughness and moisture resistance is relatively low, easy to tide fracture, generally used as furniture substrate, not suitable for use in the kitchen wet Environment. In addition, due to the higher price of E0 grade plate, consumers are usually unbearable, generally choose E1 grade plate.

Send your message to us

large roof wall color steel composite and modified phenolic fireproofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords