Kraft Paper Laminated with PP or BOPP with Window for Packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

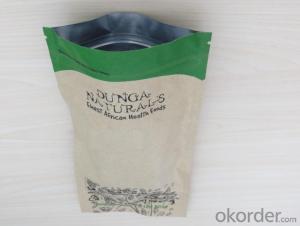

1. Description of Kraft Paper Laminated with PP or BOPP with Window for Packing:

Kraft Paper Laminated with PP or BOPP with Window for Packing are processing with imported materials,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Kraft Paper Laminated with PP or BOPP with Window for Packing mainly used for packing food such as coffee, tea, snack, powder etc.

2. Main Features Kraft Paper Laminated with PP or BOPP with Window for Packing:

Excellent quality control

Experienced facotry produced

SGS passed

3. Kraft Paper Laminated with PP or BOPP with Window for Packing Photos:

4. Kraft Paper Laminated with PP or BOPP with Window for Packing Specification:

1. Material: PE,LDPE,HDPE with Craft paper etc

2.Size:10*10000px or Customized

3.Thickness:10-200um

5.FAQ of Kraft Paper Laminated with PP or BOPP with Window for Packing:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Duck sauce made of pure aluminum foil vacuum packaging bag or transparent plastic?

- PET thin film / foil / nylon //PE thin film, it is best for the duck packaging, the longest period of hedging. Of course, there are some other place form, slightly reduce some costs, such as the PET// //PE aluminum foil film, but the effect was not as good as the former good bag, a bag to reduce the cost of not much, but the effect is significantly reduced, so it is recommended to use the former.

- Q: How are food bags made out?

- The layout of printing: in food packaging printing machine is prepared with coated, and then printing according to the first layer material food company confirmed, as a food packaging bag is usually composed of three layers compounded. Printing requires printing only one layer of the surface. Printed with design renderings have no difference. Dongguan Yu packing is a nine color full automatic computer controlled printing press. The printing effect is comparable to that of the poster.

- Q: What about the use of plastic bags?

- Now all walks of life have the use of plastic packaging bags, only grades, such as the food market is the worst, supermarkets in general, and then to food packaging non-toxic environmentally friendly plastic bags. There are advantages and disadvantages. If it is a new material, the printing ink is also non-toxic. You can use it safely. If you use recycled materials, there is a foul smell. That's bad. What's more, we will bring plastic bags to the cooked food, it is best to buy from the supermarket, come back after the food will be taken out, to avoid food and plastic bags long-term exposure, chemical reaction products. That's bad for your health.

- Q: Do vacuum packing bags have to be vacuum packed?

- Vacuum packaging bags and vacuum packaging machines are related. Vacuum packaging machine not only can complete vacuum extraction, but also can complete heat sealing packaging in vacuum, and ensure vacuum in vacuum bag can meet the requirement.

- Q: What kind of material is the express package on the market now? It's dark in the outer grey.

- The materials used for express bags are generally HD-PE, which can be recycled and can be re packed into bags

- Q: Which kind of transparent vacuum packing bag 16 wire and 24 wire?

- The so-called silk is a unit, a trace of =0.01mm, from this point of view, the bag is thicker, the more difficult to leak, so the 24 wire than the 19 wire better.

- Q: What are the requirements of the gas in the package?

- The higher requirements are modified packaging: oxygen, nitrogen and carbon dioxide are used to fill the package in proportion to the product - respiration - use, to extend the shelf life of the product, and outside

- Q: Printing solvent for food packing bag

- Determine the amount of water in the solvent by means of the principle of a different dissolution effect. Take the most transparent glass cylinder tube with 100ml toluene solution, take a small amount of analyte ester solvent such as toluene, evenly pour. When you just pour in toluene, carefully observe whether there is turbidity (milk white) phenomenon. If there is this phenomenon, the water content of the solvent is seriously exceeded, and the experience shows that when the moisture content exceeds 0.5%, the phenomenon is obvious. The water content test of benzene solvent can be carried out by extracting solvent from the long glass tube to observe whether there is delamination.

- Q: How many kinds of packing bags are there in the packaged foods?

- You ask about food plastic packaging, it is generally packaged with composite bags, composite materials, polyethylene (PE), polypropylene, nylon, polyester. These are the main membranes. The film is made of stretch film and blow film. Dry frozen goods, generally cooked with PET/PE., such as high temperature, it is generally nylon, composite CPP, or other composite, many kinds. I am in Dongguan, Humen, food packaging, such as alcoholic peanuts, bags, red dates bags, mask packaging bags, washing powder bags, areca bags, milk powder bags, small fish bags.

- Q: What's bread packing? Polyethylene film, waterproof cellophane, etc.

- More importantly, the use of aluminum foil / composite or polyethylene composite or aluminum foil / polyethylene composite material. Although this type of packaging is opaque, it protects against loss of vitamin B1 in bread.

Send your message to us

Kraft Paper Laminated with PP or BOPP with Window for Packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches