Craft Paper Laminated with Plastic Film with Round Window for Packing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Craft Paper Laminated with Plastic Film with Round Window for Packing:

Craft Paper Laminated with Plastic Film with Round Window for Packing are processing with imported materials, we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Craft Paper Laminated with Plastic Film with Round Window for Packing mainly used in the manufacture of thin films, containers, pipes, wire, wire and cable, and other daily necessities, and can be used as high frequency television, radar and other insulating material. the best choice for all kinds of products ‘packaging.

2. Main Features of Craft Paper Laminated with Plastic Film with Round Window for Packing:

Bottom Sealed Flat PE Unprinted Bags is Polyethylene odorless, non-toxic, feels like wax, has excellent resistance to low temperature performance (minimum temperature is -70 ~ -100 °C), good chemical stability, erosion resistant to most acids (not resistant to oxidizing acid), at room temperature not soluble in common solvents, water absorption, excellent electrical insulation properties.

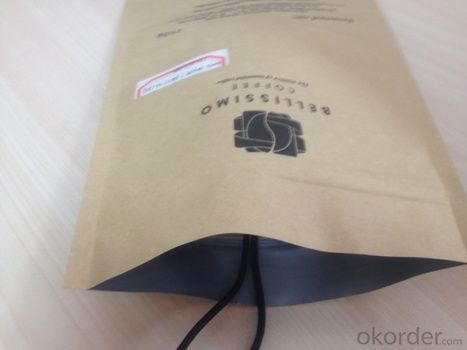

3. Craft Paper Laminated with Plastic Film with Round Window for Packing Images:

4. Craft Paper Laminated with Plastic Film with Round Window for Packing Specification:

1. Material: Laminated material

2.Size:20*750px or Customized

3.Thickness:0.03mm-0.15mm

4.Form:top open bag,ziplock bag, or Unprinted bag

5.FAQ of Craft Paper Laminated with Plastic Film with Round Window for Packing:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q:What is the material for edible fungus stick packing bag?

- High pressure polypropylene bag, the bag has the characteristics of high temperature and high pressure, it can reach 120 degrees and not easily deformed. It is the first choice for factory cultivation.

- Q:What ink is the food packing bag printed on?

- Because of this, benzene soluble chlorinated polypropylene ink has been gradually eliminated, and in Europe and other developed countries have gradually introduced or banned the use of benzene soluble chlorinated polypropylene ink laws and regulations.

- Q:What products need plastic packing bags?

- Need to use plastic bags do not have too much garbage bags, food bags, beverage bags, commodity bags, clothing bags, plastic bags are closely related to human, as long as you want, we can use plastic bags for packaging, plastic just different ingredients. Because plastic bags are convenient to carry and relatively low cost, they are well known to people.

- Q:What material is the vacuum packing bag, please?

- Vacuum packaging is a general term for flexible packaging composite membrane products. If the temperature is different, there will be a lot of division: there is less than 100 bactericidal, and some need 100 degrees of sterilization, and 121 degrees and 135 degrees.

- Q:How can the labels affixed to the bags be removed quickly?

- Use the hair dryer to adjust the hot air to the label. When the label is heated, the glue will melt so that it can be torn off easily. This method is suitable for metal and plastic tools, characterized by quick.

- Q:How to evaluate the quality of a food packaging bag design? From what angle?

- Most importantly, the design of this package has a direct sensory connection to this product. Let's take a simple example, moon cake, which is a more common packing, is packed in a plastic bag and can only buy a few dollars, but it will appreciate a lot more when it is put into the gift box. It's in the bag. Moon cake is just food. In the gift box, it becomes a gift. Before consumers buy, the product is analyzed as a food or a gift, which is the most important message that the mooncake package conveys to the consumer.

- Q:Is the color of cement packing bags related to cement?

- Portland ash cement, fly ash, silicate sleep and composite Portland cement -- black or blue.The cement packing bags shall clearly indicate the standards of implementation, cement varieties, codes, strength levels, producers' names, production licence marks (QS) and serial numbers, serial numbers, date of packing and net contents.

- Q:What does "TM" mean in a food package?

- TM is common in foreign trademarks. It is the abbreviation of "trade mark" in English. "Trade mark" means "commercial mark" in Chinese, so "TM" means "trademark""

- Q:What's the raw material of the cement packing bag?

- The quality of cement packing bags directly affects the shelf life of cement. Bags of cement raw material is polypropylene resin, mainly for foreign production of polyethylene (PE), mainly for the domestic production of polypropylene (PP), then add some additives, after the heating wire drawing, then weaving, printing and so on, the higher the quality of the cement bag inner lining!

- Q:What are the common materials of tea packing bags?

- Metal cans for the advantages of extrusion resistance, good texture, early mainly with PE bag packaging for tea packaging, but because the price is high, and easy to corrosion and rust deformation, has been gradually phased out. The metal cans within the paint smell and cover mouth closed enough should not be used alone.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Craft Paper Laminated with Plastic Film with Round Window for Packing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords