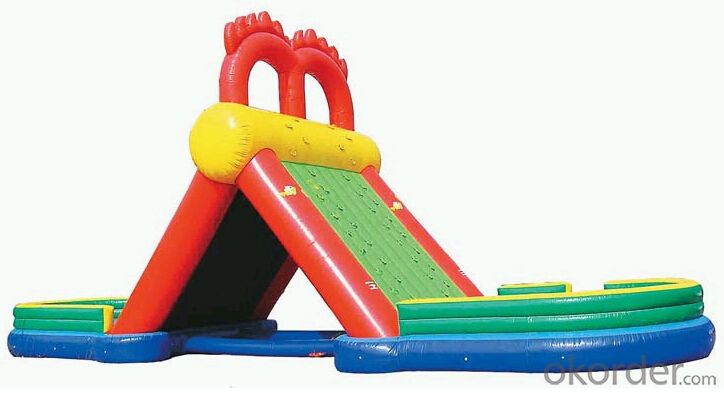

Kids Jumping tall Inflatable Playground Bounce House

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

Inflatable Castle Inflatable bouncy for kids play

0.55mm PVC tarpaulin,thickness heavy-duty, laminated and coated pvc fabric. Our materials are puncture-proof, fire-resistant and comply with SGS& ASTM (American Society for Testing and Materials) toy safety standards.

Specifications

1.Material:0.55 PVC

2.blower:CE/UL/ROHS

3.Warranty: 3 years.

4.MOQ:1PC

5.Shipment:by sea/air

Quality control:

1. Double stitching throughout the unit with triple stitching

2. Quadruple stitching in key areas inside the base. Extra webbing reinforced strip on all the stress points and interior panels

Come with:1. 2 years warranty 2. FREE blower(if customer want to buy the blower) 3. repair kits 4.Safe rule 5.Banner with your phone No/company name

FAQ:

1. How can you clean it?

Just use soap and water. Do not use any kind of solvents.

2. What is the shipping way?

It depands on yours. We usually ship Port of Qingdao Port.

3. Can you design for us?

Yes. We have a professional team having rich experience in greenhouse design and manufacturing. It does not matter if you do not have someone to complete files. Send us high resolution images, your Logo and text and tell us how you would like to arrange them. We will send you finished files for confirmation.

- Q: What are the hazards of plastic oiler

- Fire easily, easily bitten by rats, cold oil solidification also fell out.

- Q: What are the advantages and disadvantages of plastic packaging materials?

- First of all, we must say that the biggest feature of plastic packaging materials is light quality and good mechanical properties. For many goods which require long-distance transportation, it can reduce the weight of transportation and facilitate transportation. This is incomparable to glass and metal materials.

- Q: Can olive nets be used for both mechanical and hand harvesting?

- Yes, olive nets can be used for both mechanical and hand harvesting.

- Q: Do olive nets affect the overall appearance of the olive tree orchard?

- Yes, olive nets do affect the overall appearance of the olive tree orchard. When olive nets are placed over the trees to protect the fruit from birds or to collect falling olives, they can alter the aesthetic appeal of the orchard. The nets create a visible barrier that can be seen from a distance and may obscure the natural shape and foliage of the olive trees.

- Q: Can olive nets be used in different climates?

- Yes, olive nets can be used in different climates. Olive nets are designed to protect olive trees from pests, birds, and wind. They are made from durable materials that can withstand various weather conditions, including hot summers, cold winters, and rainy seasons. Additionally, olive nets are versatile and can be easily adjusted or modified to suit different climate needs, such as adjusting the mesh size or adding additional layers for extra protection.

- Q: How can plastics be cleaned?

- Now there is a good way to break the surface of plastic and remove dirt easily. Just use the tea bag we drank. There are also fried or non edible waste oil. How do you do it? It's simple。 Make sure the tea bags are dried first. Then, immersed in the used oil, wipe gently in the dirt, dirt is melted, a little off, then the plastic stay above a thin layer of oil, then we use a soft cloth to pour a small amount of detergent can clean. Also, no taste

- Q: Can olive nets be used for olive tree wind protection?

- Yes, olive nets can be used for olive tree wind protection. Olive nets are typically used to cover the olive trees and protect them from various external factors such as winds, pests, and birds. They provide a physical barrier that can reduce the impact of strong winds on the olive trees, preventing damage to the branches, leaves, or fruit. Additionally, these nets can also help in maintaining a stable microclimate around the trees, reducing the chances of water loss and maintaining optimum growing conditions.

- Q: What are the grades of plastics from 1 to 7?

- The United States Plastics Industry Association (Society of Plastics Industry, SPI) made use of plastic products of plastic type sign code, is composed of representatives of the circular triangle in the middle of the three arrows mark, plus the numbers, they will recover triangle marking attached to the plastic products, and with the numbers 1 to 7 and English abbreviations to refer to the use of plastic resin type generation. As a result, the identification of plastic varieties has become simple and easy, and the cost of recycling has been substantially reduced. Today, many countries in the world have adopted the SPI logo scheme. China enacted almost identical labeling standards in 1996.

- Q: How do olive nets prevent olive contamination from the ground?

- Olive nets prevent olive contamination from the ground by acting as a physical barrier between the olives and the soil. These nets are spread out underneath the olive trees, catching the olives as they fall from the branches. By keeping the olives off the ground, the nets prevent contact with soil, which may contain dirt, debris, or potential contaminants. This helps maintain the cleanliness and quality of the olives, reducing the risk of contamination and ensuring a higher standard of olive production.

- Q: Are olive nets suitable for both young and mature olive trees?

- Yes, olive nets are suitable for both young and mature olive trees. Olive nets are used to protect the olives from birds and other animals, as well as to collect the olives during harvest. These nets can be easily placed over the tree regardless of its age, making them suitable for both young trees that are still growing and mature trees that are ready for harvest.

Send your message to us

Kids Jumping tall Inflatable Playground Bounce House

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords