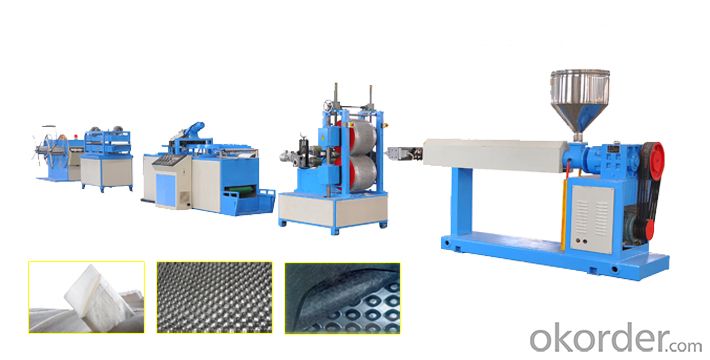

JSM-Automatic Forming Units of PE Drainage Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stracture Features:

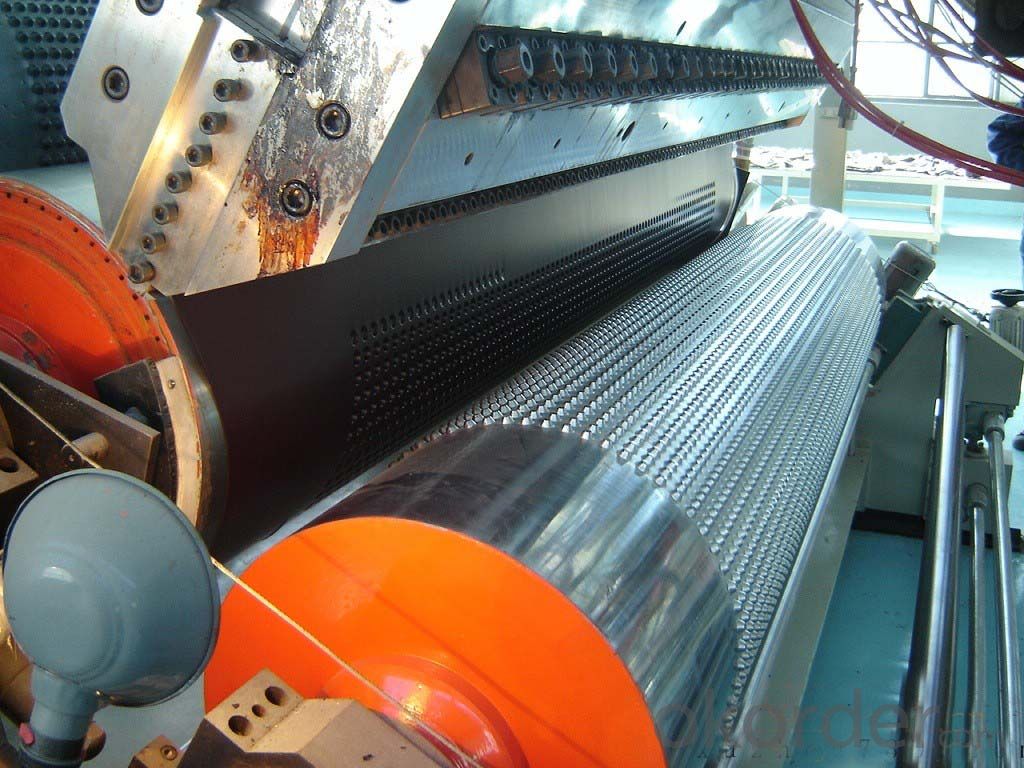

PE Drainage Board Rolling Suction Machine is an innovative machinery in China. Compared with the old-fashioned forming process, this equipment forms a whole continuous sheet of drainage board at one time with high efficiency, low energy consumption. It also solved the problem that the compression strength of old rolling forming drainage sheet is not ideal. After unique mechanics design, the convex wall thickness of the circular convex on the drainage board is well-proportioned. Meanwhile, the compression strength is over 50% higher than similar products which solve the problem that the compression strength of domestic drainage board made of HDPE is not ideal and ensures long-term loaded compression tolerance. Plastic drainage board is a kind of multi-functional membrane coiled materials performing comprehensive protection, professional waterproofing and drainage. Its quality is up to the international advanced level, completely changes the situation that high-quality drainage board can only rely on import. All the equipments, from the calendars, tractor to the rolling machine, are all especially designed and manufactured based on the structure of drainage board. The thickness range of the output board is 0.5mm-5.5mm, width up to 5000mm.

Specification:

1. Raw Materials: High-low pressure PE Mater-batch.

2. Equipment configuration (3000 width).

(1) Master-batch Mixer: Mixed volume:300L, Mixed ability: 500kgs/h, Mixed Power:3Kw.

(2) Automatic Loading Machine: Motor power: 1.1kw, Loading capacity:500kgs/h

(3) Singly Screw Extrusion Machine.

Screw Diameter: 150m; Length – Diameter Ratio: 30:1; Screw Rotate Speed: 0-75rpm

Main Motor Power: 160KW; Frequency Conversion Speed Modulation Method: variable frequency motor, Taiwan frequency converter.

Heating Power: about 80kw; Extrusion alibity: 300-800kg/h

Heating Circle: Multistate-cast-aluminum heating circle; Screw Nut Material: 38CrMoAl Nitriding Treatment.

Nitriding Depth: 0.4-0.7mm Nitriding Rididity: HV720-940

Electric Control Cabinet: Omron Temperature Control, LG Surrenttra Former Contactor.

(4) Handmade Ring Screen or Oil Pressure Screen Exchanger (Optional)

(5) Clothes-rack shape Flat Mould, Chrome-faced treatment.

(6) Forming Roller: available form diameter is about 700-800mm; Length is 3300mm.

(7) Traction: Taiwan frequency converter, Frequency conversion speed modulation.

FAQ:

Where is your factory located:

Our production base is located in Zhejing Province.

Will your side be responsible for installation, is it for free?

We will be in charge of installation, but you have to pay related fee.

What is the advantage of your company?

Our company is the largest building materials and equipment suppplier in China, second in the world, as a state-owned company, we strictly focus on quality management, our production is under the standard of IS0 9001. for the more, we have experienced logistic team, which is responsible for puntual deilivery and cheapes shipping charge.

- Q: when I use armature voltage feedback (host start speed 50, normal can produce 10It is normal to start at 80 or 150 of the speed, but after a few minutes the motor does not turn. 590 alarm (missing pulse alarm). When I change the feedback mode to speed feedback, my host sometimes starts and sometimes fails to start. I hope you help me, how should I adjust?. Thank you。

- You can adjust the proportional gain, and if you don't move, the parameter has this problem, you should check to see if you really lost the pulse

- Q: Why is the connection between the extruder and the switchboard?. The upper and lower three terminals are short circuited

- The action should be to require three simultaneous electricalOr a two way backup

- Q: Why will the extruder frequency shift stop?

- Because the frequency converter is out of order, you can look at the fault record parameters of the inverter.

- Q: What are the common extrusion molding products?

- A plastic pipe, including water supply and drainage pipe, casing and other electrical B plastic doors and windows just C a variety of wire, cable, cable break, also includes a data line, wire headset D PVC ceiling e for plastic guardrail protection f roadside flowers and some decorative strips, temporary thought so much, there are a lot of specific products and you look at the things around you can think of

- Q: Can PC and PP be extruded together with two materials in an extruder?

- No co extrusion, PC polycarbonate, PP polypropylene, two kinds of product structure is not the same, not the same chemical composition, viscosity and liquidity is not the same, processing temperature and processing technology is also very different, and two kinds of products, so not incompatible, CO extrusion.

- Q: Extrusion blow molding machine, storage or continuous type good?

- This is not good or bad, depends on what your product is If the product cycle large volume high capacity is bound to produce a product with storage because of your long,

- Q: Where is the Huangyan extruder machine?

- You want to see what type of mold processing, but Masino comprehensive, injection mold, blow mold, mold and so on can be developed.

- Q: Wire and cable extrusion machine extrusion die how to quickly adjust the core degree, how can I touch it by hand?,

- See section - cross section. Setting adjustment with RPC

- Q: How to adjust the 65 screw gap in the extruder?

- That's the tune.This should be practical learning. The outlet plane of the barrel is about 3 mm in diameter.

- Q: Is the extruder the same as the extruder?

- Extrusion machine, also called extruder, and is mainly used for power line, power cable, coaxial cable, communication cable, transmission cable, BV type civil line, electronic wire, computer wire, building line, data communication cable, RF cable, HDMI cable, cable, all kinds of high temperature silicone Teflon, core line line, network cable, optical fiber, rubber insulated wire cable wire and cable extrusion wire and cable equipment.

Send your message to us

JSM-Automatic Forming Units of PE Drainage Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords