HZS60 Concrete Batching Plant / ISO & CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The product is widely used in key projects like various highways, railroads, high-speed railways, airports, ports, bridges, and hydropower stations, as well as commercial concrete mixing station, real estate, and municipal construction. With constantly increasing investment in technological innovation, the company has achieved great achievements and been recognized as “Provincial Enterprise Technology Center” in 2008. The company has 4 research department respectively specializing in mixing, transportation, conveying, and automation.

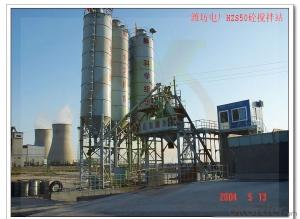

Concrete mixing plant HZS60

Theoretical productivity 60m3/h

Mixer model JS1000

Mixer nomination capacity 1000L

Mixing largest aggregate 80mm

Mixing motor power 2x18.5kw

Aggregate lifting belt motor power 15kw

Aggregate conveying belt width 650mm Side trough belt

Aggregate lifting belt conveying capacity 350t/h

Aggregate batcher PL2400

Aggregate bin capacity 3x12m3

Aggregate batching capacity 2400L

Aggregate types 3

Powder bin capacity 50/100t(Optional)

Screw conveyor 35t/h

Aggregate measuring precision ±2%

Powder measuring precision ±1%

Water measuring precision ±1%

Additive measuring precision ±1%

Discharging height 3.8m

Power 100kw(Without screw conveyor)

Weight 50t(Without screw conveyor and cement bin)

Dimension Depends on the configuration and equipment layout

- Q: What is the concrete of the mixing station?

- What else can you do to sell concrete What is the station

- Q: Cement warehouse introduction, storage reserves?

- This one has a lot of small, see how to configure, usually at 200 tons above each warehouse

- Q: How much concrete is produced per hour by HZS180 concrete mixer?

- HZS180 concrete production line equipment production line equipment per hour theory produces 180 cubic concrete. It depends on the equipment situation. Henan zheng a heavy industrial concrete mixing plant equipment factory

- Q: How to choose a good concrete mixer station?

- Selection is best good survey is supply and demand situation of you and how many mixing station, concrete demand how, don't blindly pursuing big equipment, vehicles and personnel left unused, but it is now generally good, as long as the operation, mixing station not at a loss

- Q: What constitutes the js750 concrete mixing station

- pecific configuration can be cut can be numerous js750 hosts are commonly used to climb a pipe loading, the concrete quality requirement is not high do not need automatic batching only buy a belt bucket host to climb to go, with a tractor modified small forklift about yao to climb add material in the bucket.

- Q: How long does it take to build a concrete mixer station?

- The main idea is that the goods are completely incomplete, and the crane, the manpower, the mechanical tools. If everything is in place, then the pure installation will be two weeks to a month. Of course, also see you buy what type of product, container type is compared commonly faster, smaller and faster, under 3000 type slightly faster, 4000 and 5000 slowly

- Q: What are the facilities of the concrete mixing station

- One. Stir the host The mixing machine is divided into strong mixing and self-falling stirring. The powerful mixer is the mainstream in the domestic and foreign mixers, it can stir the liquid, semi-dry hard and hard and so on. The main mixing liquid concrete of the self-falling mixer is very rarely used in the mixing station. Two. Material transport system The material transport consists of three parts. Aggregate conveying; There are two ways of conveyance and belt conveyance. The advantage of hopper promotion is that the area is small and the structure is simple. The advantage of belt transport is that the transport is large, efficient and low. The belt conveyor mainly applies to the mixing stations that have aggregate storage, thereby increasing the productivity of the mixing stations. Powder conveying; The powder used in concrete is mainly cement, fly ash and mineral powder. The most commonly used powder conveyors are conveyors of screw conveyors, and the large mixing buildings are carried by pneumatic conveyer and scraper. The advantages of screw transport are simple structure, low cost and reliable use. Liquid transport mainly refers to water and liquid admixtures, which are delivered separately by water pumps.

- Q: How much concrete is produced by the js1000 type of the concrete mixing station

- The JS1000 is only the mainframe model and depends on the power of the whole machine and the size of the batching machine. The JS1000 has HZS50, 60, 75, which is in theory, 50, 60 and 75 per hour. The actual operation is certainly less, about 80%

- Q: What is the difference between a concrete mixer and a concrete mixer

- The bone material of the mixing tower is on the top, and the aggregate is measured directly into the mixer. The concrete bin of the commercial concrete station is below, and the bone material is measured and then transported into the mixer after being transported by the inclined belt (which also has some use of the elevator). In a popular way, it is called the building, which is called the second ascent. The steel structure will be larger and the diagonal belt will be relatively longer because of the bone material in the mixing building. But in productivity, the churn is about a fifth higher than the commercial concrete station. In operation, because the inclined belt of the commercial concrete station starts frequently, the energy consumption and the failure rate will increase, and the energy consumption of the mixing building is lower than the failure rate. In the end, because the production capacity of the concrete station is small, the structure is easily disassembled and can be made into a container transfer site, which is suitable for the construction site. The mixing tower is large and high in productivity, and can only be used as a fixed mixer, suitable for the supply of large water projects or large quantities of goods. So customers in the difference between commercial concrete, concrete stand and commodity concrete mixing floor, from aggregate (material), the production efficiency and so on, to choose and buy the right equipment.

- Q: Concrete mixstations belong to no special equipment

- Is not mixing station is places or facilities, equipment, for whether the equipment belongs to the special equipment to check the catalog of special equipment, included in the directory is the special equipment, is not included.

Send your message to us

HZS60 Concrete Batching Plant / ISO & CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords