Hydraulic Jacking Bridge /Construction Hoist /Material Hoist /Industrial Hoist

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

This equipment is used combined with multifunctional hoist in cooling tower construction. It can be attached to the hoist, providing a platform for horizontal transportation of steel bars and concrete.

Features:

1. The bridge body and the level bridge are well shaped structure with good rigiity and precise stress.

2. The hydraulic jacking method ensures safety and convenience during the operation of the bridge

3. The operation scope can be adjusted according to the constuction precedure of the building

4. At the top of the bridge there is a minor downward slew tower crane which is used for the lifting of steel bars and materials.

5. To ensure the safety during the operation, it is installed with sensitive lifting, slewing, range-change, torque limiting mechanisms and front-rear bridge torque alarms.

6. The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions.

7. The system applies the special software for hoists developed by our company, making the operation more safe and reliable.

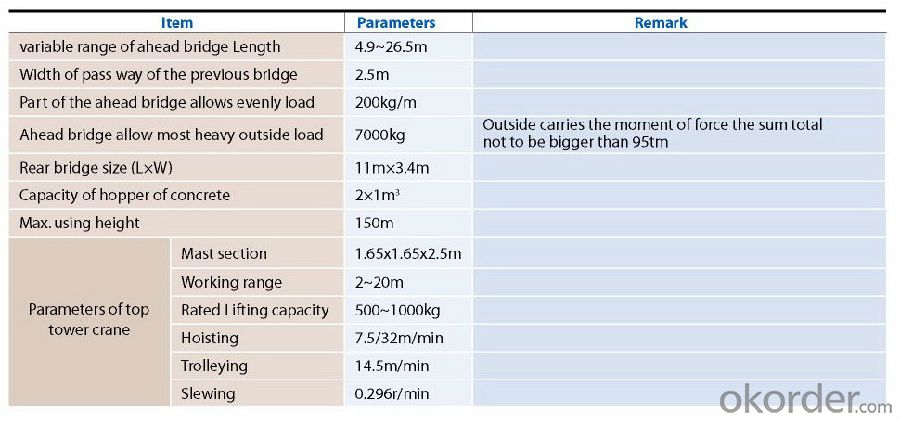

Specifications:

- Q: This question asks for a comparison of the pros and cons of utilizing hydraulic cylinders in the context of building hoists.

- <p>Hydraulic cylinders in building hoists offer several advantages, including high force output, compact size, and precise control. They provide smooth and controlled lifting, which is crucial for heavy construction materials. Additionally, hydraulic systems can generate large amounts of force with relatively small cylinders, making them space-efficient. The disadvantages include potential leaks, which can be hazardous, and the need for regular maintenance to ensure the system's reliability. Hydraulic systems can also be more complex to install and repair compared to electric or manual systems. Furthermore, they require a constant power source, which might not always be readily available on construction sites.</p>

- Q: This question asks about the process of installing a building hoist, a piece of equipment used in construction to lift materials and personnel.

- <p>Installing a building hoist involves several steps: 1) Site preparation, ensuring the area is level and stable. 2) Unpacking and inspection of the hoist components. 3) Assembling the hoist tower, starting with the base and working upwards. 4) Installing the drive mechanism and control panel. 5) Rigging the hoist cables and safety devices. 6) Conducting a thorough inspection and testing the hoist to ensure it operates safely. 7) Obtaining any necessary permits and approvals. 8) Training operators on the safe use of the hoist. Always follow the manufacturer's instructions and local regulations when installing a building hoist.</p>

- Q: What are the benefits and drawbacks of utilizing a building hoist in construction?

- <p>Advantages of using a building hoist include increased efficiency in material transportation, reduced manual labor, and improved safety by minimizing the risk of accidents associated with manual handling. They can also speed up construction timelines by allowing for continuous material flow. Disadvantages include the initial cost of the hoist, the need for regular maintenance, and potential downtime in case of mechanical failure. Additionally, building hoists may have limited capacity and may not be suitable for all types of construction projects, especially those with irregular shapes or limited space for installation.</p>

- Q: What steps are necessary to guarantee the safety and reliability of a building hoist?

- <p>To ensure a building hoist is safe and reliable for use, follow these steps: Conduct regular inspections and maintenance by qualified personnel. Check all mechanical and electrical components for wear and tear. Ensure all safety features, such as emergency stop buttons and limit switches, are functioning correctly. Verify that the hoist is properly secured to the building and that all load-bearing elements are capable of handling the weight. Adhere to the manufacturer's guidelines and specifications for operation. Train operators on the proper use of the hoist and emergency procedures. Regularly test the hoist's load capacity and stability. Keep records of all inspections, maintenance, and any incidents for future reference.</p>

- Q: How many kw is the sc construction elevator

- A double cage, the three-drive is 11 * 3 * 2KW and the two drives are 12 * 2 * 2KW

- Q: This question asks about the typical issues that can arise with building hoists, which are mechanical devices used in construction to lift materials and workers.

- <p>Common problems with building hoists include mechanical failures such as broken cables or chains, malfunctioning brakes, and worn-out gears. Electrical issues like short circuits or damaged control panels can also occur. Safety hazards may arise from improper installation or maintenance, leading to accidents. Overloading the hoist can cause structural damage and failure. Environmental factors like extreme weather conditions can affect performance and longevity. Regular inspections and maintenance are crucial to prevent these problems and ensure the safe operation of building hoists.</p>

- Q: How many meters or how many layers should the construction elevator be installed?

- In the guangdong area, the first installation and acceptance of the equipment will be below 7 levels, and more than 7 floors will be charged for the inspection. Another 9 meters per wall, the most suitable installation time is a building at least 12 meters, which can be installed at 21 meters in the evening.

- Q: This question asks for the safety precautions that should be taken when operating electric-hydraulic construction hoists.

- <p>Safety measures for using electric-hydraulic building hoists include regular maintenance and inspection to ensure all components are in good working order. Operators must be trained and certified, following all safety protocols. Never exceed the hoist's load capacity. Ensure that safety hooks and chains are in place and secure. Keep the hoist area clear of debris and unauthorized personnel. Use proper lifting techniques and avoid sudden starts or stops. Always inspect the load before lifting to ensure it is stable and secure. Emergency stop switches should be easily accessible. Ensure that all safety guards are in place and functioning properly. Adhere to all local regulations and manufacturer's guidelines.</p>

- Q: Explain the key differences between electric and hydraulic lifting equipment, including their power sources, efficiency, and applications.

- <p>Electric lifting equipment is powered by electric motors and typically operates through cables or batteries, making them quieter and more environmentally friendly. They are often used in indoor settings where noise and emissions are a concern. Hydraulic lifting equipment, on the other hand, uses hydraulic fluid and pistons to generate force, providing high power and torque. They are commonly used in heavy-duty applications and outdoors. Electric systems are generally more energy-efficient and have lower maintenance costs, while hydraulic systems offer greater power density and can handle heavier loads.</p>

- Q: Is it possible to employ a building hoist for demolition purposes?

- <p>While a building hoist is primarily designed for construction purposes, such as lifting materials and personnel to different floors, it is not typically recommended for demolition work. Demolition requires specialized equipment that can handle the specific stresses and hazards associated with breaking down structures. Using a building hoist for demolition could be dangerous and may not comply with safety regulations. It's crucial to use equipment specifically designed for demolition tasks to ensure the safety of workers and the effectiveness of the operation.</p>

Send your message to us

Hydraulic Jacking Bridge /Construction Hoist /Material Hoist /Industrial Hoist

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords