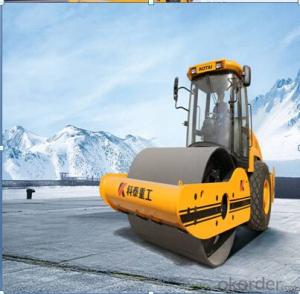

Hydraulic Double Drum Vibratory Rollers HDD630D/640

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 35 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hydraulic double drum vibratory rollers are manufactured according to international advanced technology and by use of imported main components abroad, suitable for compaction of various stabilized soils and bituminous concrete on road surface construction, which are ideal compaction equipments for industrial sites such as highway, municipal road mending, sports ground, garden lawn, etc.

MAIN FEATURES

Reliable and powerful engine of KUBOTA with large power storage, reliable performance, to reach Europe stageⅡemission standard.

Hydrostatic travel and vibration drive in both drums with greater gradeability. Higher vibration frequency with great excited force for better road surface quality.

Hydrostatic center articulated steering, infinitely variable speeds for convenient operation. The emergency stop push button assures safety and dependability of the machine.

The original imported hydraulic components as SAUER-SUNDSTRAND travel pump、POCLAIN travel motor、CENTA shaft coupling guarantees the good performance of the whole machine.

Compact design of small size and beautiful appearance, it is suited for compaction of narrow areas. Completely open engine cover offers the optimal the space of maintaining.

MAIN PERFORMANCE PARAMETERS

HDD630B | HDD640 | ||

Operating mass Static linear load Vibration amplitude Vibration frequency Centrifugal force Travel speed Gradeability Turning radius Drum width Drum diameter Wheelbase Ground clearance Diesel engine model Diesel engine power Overall dimensions | kg N/cm mm Hz kN km/h % mm mm mm mm mm

kW mm | 3000 119/112 0.45 57 30×2 9 30 5000 1300 700 1948 220 D1703 26 2650×1380×2530 | 4000 154/154 前0.7/ 后0.3 前53/ 后55 前40/后30 10 30 3400 1300 700 2093 220 D1703 26 2790×1380×2540 |

Welcome you to visit our factory in China. Anything we can do, please feel free to let us know. We are sure your inquiries will get our prompt attention.

- Q: How much is the BMW roller 26 tons?

- BMW Dalian canal Yici engine, some structure is domestic production; there are great differences between Germany and the quality of BMW! Currently the best brand in the countryBMW rollerBMW is roller imported from Germany BMW;

- Q: How much is the rubber tyred roller?

- Tim can consult the installation of his majesty: Max technology new phonetic spelling

- Q: The width of the road is four meters. The roller runs for half an hour. It can press a large area of road

- Solution: it is known that a roller runs 25 meters per minute and the width of the roller is =4 meters,Get the roller area per minute of the roller= running length per minute * width of road=25 * 4=100 square metersAnd roller drive for half an hour, half an hour =30 minutes,Roller must be driven for half an hour= pressing area per minute * road time=100 * 30=3000 square metersAnswer: roller run for half an hour, can press 3000 square meters of road.

- Q: The difference between the vibration roller and a roller two is what is the function of a mechanical or different machinery, which is now the site of the

- The concept of two kinds of roller, vibratory roller is carried to the subgrade construction, the steel wheel vibration beating on the construction and pavement compaction, smooth wheel roller is on the road by using its own weight roller (i.e. asphalt pavement or other final compaction machinery).

- Q: How does the municipal asphalt pavement budget do not have a wheeled roller?

- Municipal asphalt pavement construction quota, already contains a roller and paving machine cost,

- Q: How big is the 20 ton bottle?

- 20 tons of roller storage battery should be 2 12V120A, and I hope to be helpful to you.

- Q: Vibratory roller pressure and steel roller compacted what is different

- You should make the cement stabilized layer of double steel wheel vibratory roller, you should first use vibratory roller vibration compaction, and then do not open vibration to smooth surface. Just do not open the vibration pressure several times, the static pressure only to surface dense, but the bottom is still more loose

- Q: Will the Apocalypse Tank be pressurized back?

- but also not explosion damage, the armor is even more powerful, not simply rely on the weight can be crushed,

- Q: Why is the price difference so large? Is there a problem of repeated calculation?

- 2 according to the quota of work content, only in the original soil roadbed rolled or compacted backfill roadbed with good artificial leveling roller.

- Q: The rollers are divided into several types

- The roller from the area can be divided into vibroll (RCC) and static (rolling), road roller vibration roller can be divided into 2 6 8 amplitude amplitude, amplitude, and refinement is based on weight and amplitude, exciting force and other distinguished models.

Send your message to us

Hydraulic Double Drum Vibratory Rollers HDD630D/640

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 35 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords