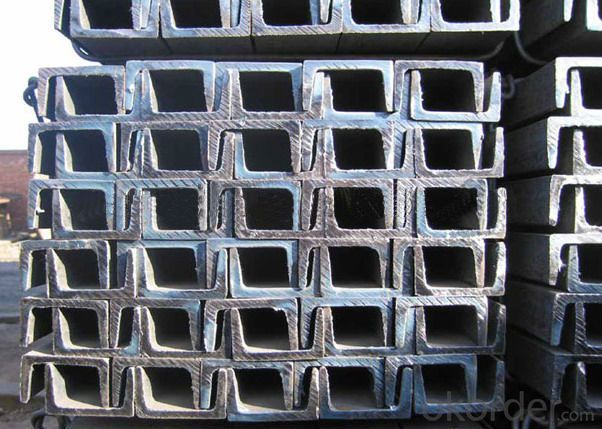

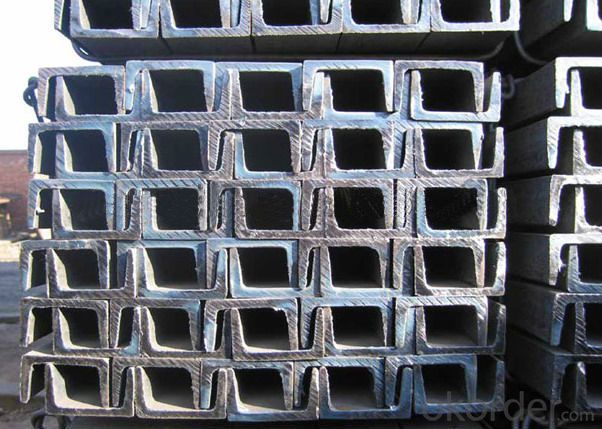

Hot Rolled U Channel Steel Module of SS400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled U Channel Steel Module of SS400 Details

| Standard: | AISI,ASTM,BS, DIN,GB,JIS | Dimensions: | 51*25*3-305*80*13mm | Grade: | Q235 Q345 Q460 SS400 SS540 A36 S235JR/ST37-2 ST52-3/S355JR |

| Place of Origin: | China (Mainland) | Brand Name: | CNBM | Model Number: | 51*25*3-305*80*13mm |

| Shape: | U Channel | Application: | construction, machine, vehicle, engineering | Perforated Or Not: | Not Perforated |

| galvanized: | galvanized or not galvanized |

Packaging & Delivery

| Packaging Detail: | in bundles. |

| Delivery Detail: | 25days after confirming your order |

Hot Rolled U Channel Steel Module of SS400 Specifications

Size:51*25*3-305*80*13mm

Legth:6m, 9m, 12m

Grade:Q235,SS400,ST37-2,S235JR,A36

Material: Q195 Q215 Q235 Q255 Q275 Q345 Q390 Q460 SS400 SS420 SS540 A36 S235JR/ST37- 2 ST52-3/S355JR/S355JRG3 12Mn 16Mn

Standard:

Chinese Standard : 50*37*4.5---400*102*12.5

JIS standard: 50*25*4-200*80*7.5

Standard: ASTM JIS GB DIN

Hot Rolled U Channel Steel Module of SS400 Pictures

- Q: How are steel channels used in the manufacturing of machinery?

- Steel channels are commonly used in the manufacturing of machinery due to their structural strength and versatility. These channels, also known as C-channels or U-channels, are typically made from hot-rolled steel and have a distinct shape resembling the letter "C" or "U". In the manufacturing process, steel channels are used for various purposes. They can be used as structural components to provide support and stability to the machinery. The channels are often used as frames or bases for equipment, providing a solid foundation for the other components to be attached to. Additionally, steel channels can be used as guides or tracks for moving parts within the machinery. By attaching rollers or bearings to the channels, machinery components can easily slide or roll along the track, enabling smooth and precise movements. Steel channels are also used as reinforcement for machinery components. They can be welded or bolted onto parts that require additional strength or rigidity. This reinforcement helps to prevent bending, warping, or distortion of the machinery during operation, ensuring its durability and longevity. Furthermore, steel channels can be used for mounting various accessories or attachments. By attaching brackets, clamps, or other components to the channels, machinery designers can easily customize and configure the equipment to meet specific requirements. Overall, steel channels play a crucial role in the manufacturing of machinery by providing structural support, guiding moving parts, reinforcing components, and facilitating customization. Their strength, versatility, and ease of use make them an ideal choice in the construction of robust and reliable machinery.

- Q: What are the common accessories used with steel channels?

- Some common accessories used with steel channels include brackets, fasteners (such as bolts, screws, and rivets), connectors, clips, and end caps. These accessories are used to secure and connect steel channels to other structural elements, provide additional support, and enhance the overall functionality and stability of the channel system.

- Q: Can steel channels be used for machinery support?

- Yes, steel channels can be used for machinery support. Steel channels are often used in industrial applications as they provide excellent structural support and can withstand heavy loads. They offer stability and durability, making them suitable for supporting machinery and equipment.

- Q: What are the different shapes of steel channels?

- There are a variety of shapes and sizes of steel channels available to meet different structural and construction needs. Some commonly seen steel channel shapes include: 1. C Channel: Also referred to as a C-shaped channel, it features a straight back and two perpendicular legs. This shape offers excellent structural support and is frequently utilized in building frames, supports, and industrial applications. 2. U Channel: Similar to the C channel, the U channel has a straight back and two parallel legs. It is commonly used as a support for building structures, trailers, and vehicles. 3. Hat Channel: This type of steel channel has a wide, flat top that resembles a hat, with two legs extending downward at an angle. Hat channels are often used for roofing and wall framing in residential and commercial construction. 4. Z Channel: The Z channel is shaped like the letter "Z," with one flange extending upward and the other flange extending downward. It is commonly employed for purlins, studs, and construction applications that require enhanced strength and stability. 5. Box Channel: Box channels have a rectangular shape with four sides of equal length. They are frequently used in construction projects that necessitate structural support, such as for beams, frames, and trusses. These examples represent just a few of the various shapes of steel channels that are available. The selection of a particular shape depends on the specific application and structural requirements of the project.

- Q: Are steel channels suitable for use in the construction of machinery frames?

- Yes, steel channels are commonly used in the construction of machinery frames due to their strength, durability, and versatility. Steel channels provide excellent structural support and can withstand heavy loads, making them suitable for supporting the weight and various components of machinery. Additionally, steel channels offer flexibility in design, allowing for customization to meet specific requirements of the machinery frame. They are also resistant to corrosion and can withstand harsh environmental conditions, ensuring long-term functionality and reliability. Overall, steel channels are a reliable choice for constructing machinery frames, providing stability, strength, and longevity.

- Q: What are the different types of connections used for steel channels?

- Various types of connections are utilized for steel channels depending on the specific application and structural needs. Some commonly used connections are as follows: 1. Welded Connections: Welding is a prevalent method for joining steel channels. This process involves melting the channel ends and fusing them together using heat. Welded connections are known for their strength, durability, and excellent load-bearing capacity. 2. Bolted Connections: Bolted connections involve the use of bolts, nuts, and washers to connect steel channels. Holes are drilled in the channels, and bolts are inserted through these holes and tightened with nuts. Bolted connections offer easy installation, flexibility for disassembly, and can be adjusted or replaced if needed. 3. Riveted Connections: Riveting is an older method of connecting steel channels that involves using rivets. Rivets are inserted through pre-drilled holes in the channels and then hammered or pressed to secure them in place. Riveted connections provide strength and stability, although they are less common nowadays due to the labor-intensive installation process. 4. Composite Connections: Composite connections combine different connection methods to enhance overall strength and performance. For instance, a composite connection may utilize a combination of welding and bolting, providing the advantages of both methods. These connections are often preferred for high-load applications or when specific design requirements must be met. 5. Moment Connections: Moment connections are employed to transfer bending moments between steel channels. These connections are designed to withstand rotational forces and provide stability. Moment connections are typically created through welding and require meticulous design and engineering to ensure proper load distribution and structural integrity. It is important to consider factors such as load requirements, structural design, fabrication capabilities, and project specifications when selecting a connection type. Consulting a structural engineer or a professional with expertise in steel channel connections is highly recommended to ensure the appropriate connection type is chosen for a specific application.

- Q: Can steel channels be used for aesthetic purposes in architectural designs?

- Yes, steel channels can certainly be used for aesthetic purposes in architectural designs. Steel channels are versatile structural elements that can be used in various architectural applications, including both functional and decorative purposes. In terms of aesthetics, steel channels offer a sleek and modern appearance that can enhance the overall visual appeal of a building or structure. They can be used to create distinctive and eye-catching designs, as their unique shapes and profiles can add a sense of depth and dimension to architectural elements. Steel channels can be incorporated into architectural designs in a variety of ways. They can be used as exposed structural elements, such as in the construction of bridges or walkways, where their clean lines and geometric shapes can create a visually striking effect. Additionally, steel channels can be used as decorative features, such as in the design of staircases or railings, where their sleek and contemporary look can add a touch of elegance and sophistication to the space. Furthermore, steel channels can be finished in a wide range of colors and textures, allowing for customization to match the desired aesthetic theme of a project. They can be painted, powder-coated, or even left in their natural steel finish, depending on the desired visual effect. Moreover, steel channels offer durability and strength, making them suitable for a wide range of architectural applications. They are resistant to corrosion and weathering, ensuring their longevity and low maintenance requirements. In conclusion, steel channels can definitely be used for aesthetic purposes in architectural designs. Their versatility, sleek appearance, and durability make them a popular choice for architects and designers looking to create visually appealing and contemporary structures. Whether used as exposed structural elements or decorative features, steel channels can add a touch of sophistication and modernity to any architectural design.

- Q: Are steel channels suitable for use in bridges?

- Yes, steel channels are suitable for use in bridges. Steel channels offer several advantages that make them a popular choice for bridge construction. Firstly, steel channels are known for their high strength-to-weight ratio, which allows for the construction of lightweight yet durable bridges. This is particularly important in areas with limitations on the weight that can be supported by the ground or existing infrastructure. Additionally, steel channels provide excellent resistance to corrosion. Bridges are often exposed to harsh environmental conditions, such as rain, snow, and moisture, which can cause deterioration of the materials used. Steel channels are typically made from corrosion-resistant alloys or are coated with protective layers, making them highly durable and ensuring the longevity of the bridge structure. Furthermore, steel channels offer versatility in design and fabrication. They can be easily shaped, cut, and welded to meet specific project requirements, allowing for the creation of intricate bridge designs. Steel channels also provide the flexibility to adapt to different load-bearing capacities, enabling engineers to construct bridges that can accommodate varying traffic volumes and weights. Lastly, steel channels have a long history of successful use in bridge construction. They have been extensively tested and proven to withstand heavy loads, extreme weather conditions, and provide long-term structural integrity. In conclusion, steel channels are a suitable choice for use in bridges due to their high strength-to-weight ratio, resistance to corrosion, versatility in design, and proven track record of performance.

- Q: Use two long five meters of 10# channel steel load-bearing frame, the maximum load is?

- 8 channel steel and 40*60 square steel tube, which is good in bending strength?

- Q: How do steel channels perform under impact loads?

- Steel channels exhibit excellent performance when subjected to impact loads. Their ability to effectively absorb and distribute impact energy, coupled with their structural design and material properties, minimizes the risk of damage or failure. The structural shape of steel channels, featuring flanges and web, contributes to their increased stiffness and rigidity, thereby enhancing their capacity to withstand impact loads. Furthermore, the utilization of high-strength steel in the manufacturing process of steel channels further improves their resistance to impacts. This guarantees that steel channels can resist deformation and maintain their structural integrity even when exposed to significant impact forces. In conclusion, steel channels are a dependable choice for applications where impact loads are a concern as they offer a high level of performance, ensuring the safety and durability of structures or systems.

Send your message to us

Hot Rolled U Channel Steel Module of SS400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords