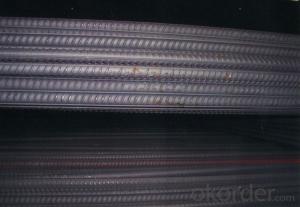

Hot -rolled bar 400MPa

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HRB400 is a kind of name of the new standard of reinforced, as one of the hot rolled ribbed steel bar. The name of the new standard for HRB400 reinforced, tertiary rebar for old said, as one of the hot rolled ribbed steel bar. In the construction industry, tertiary rebar is the last term.

Of the brand by HRB and number of hot rolled ribbed steel bar yield point of the minimum value. H, R, B Hot rolled (Hot rolled) respectively, ribbed (ribbed), steel bar (Bars) the first three words of English letters.

Classification of HRB400 -

Divided into HRB335 hot rolled ribbed bar (Numbers of 20 mnsi), HRB400 (the old number is 20 mnsiv, 20 mnsinb, 20 mnti), HRB500 three grades.

Fine grain hot-rolled reinforced its brands after the abbreviation of hot rolled ribbed steel bar and "Fine" (Fine), the first letter in English. Such as: HRBF335, HRBF400, HRBF500.

Have higher requirements of aseismatic structures for brand is: after the existing brand and E (for example: HRB400E, HRBF400E).

HRB400 - main purposes

Widely used in houses, Bridges, roads and other civil engineering construction.

HRB400 - leading producer

Rebar manufacturers in our country mainly in north and northeast, north China area such as shougang, tangshan, xuanhua, ChengGang, shanxi ZhongYang steel mills, baoding pury steel, northeast Westwood, north Taiwan, stroke, such as steel and so on, the two regions more than about 50% of the total output of rebar.

Rebar and light surface is the difference between a round bar with longitudinal and transverse ribs, usually with 2 longitudinal and cross rib of uniform distribution along the length direction. Belong to small section steel rebar, mainly used for reinforced concrete frame construction. In use requires a certain mechanical strength, bending deformation properties and welding performance. Production of raw materials of rebar steel billet calm smelting process in the carbon structural steel and low alloy structural steel, finished steel for hot rolling forming, is fire or hot rolling state delivery.

HRB400 - reverse bending performance

According to buyer's requirements, the rebar can reverse bending performance test.

Reverse bending test of curved heart diameter than the corresponding increase a rebar diameter bend test. Positively curved 45 degree first, and then reverse bending 23 degrees, reverse bending after 23 degrees. After reverse bend test, rebar bending parts surface shall not crack.

HRB400 - surface quality

Rebar surface permits can not have crack, scarring, and folding.

Rebar surface with convex block is allowed, but must not exceed the height of the horizontal rib, other defect depth and height of the rebar surface shall not be greater than their positions to allow the size deviation.

HRB400 - size, shape, weight, and allowable deviation

1. Nominal diameter range and recommend the diameter

Rebar nominal diameter in the range of 6 ~ 25 mm, standards recommended by the rebar nominal diameter is 6, 8, 10, 12, 16, 20, 25, 32, 40, 50 mm.

2. The ribbed steel plate surface shape and size of allowable deviation

Ribbed rebar cross rib shall meet the following basic requirements:

Axis transverse ribs with steel plate of beta should not be less than 45 degree Angle, when the Angle is not greater than 70 degrees, rebar relative to the direction of the horizontal rib on both sides should instead;

L cross rib and spacing shall not be greater than the rebar nominal diameter of 0.7 times;

Horizontal rib on the side and Angle on the surface of the rebar shall not be less than 45 degrees;

Rebar clearance between relative to the end of cross rib on both sides (including the longitudinal rib width) should not be greater than the sum rebar 20% of nominal circumference;

When the rebar nominal diameter is not more than 12 mm, relative costal area should not be less than 0.055; nominal diameter is 14 mm and 16 mm, relative costal area should not be less than 0.060; Nominal diameter greater than 16 mm, relative costal area should not be less than 0.065.

3. Length and allowable deviation

A, length: rebar usually according to the specified length delivery, specific delivery length should be indicated in the contract; rebar to volume delivery, each dish should be a rebar, allowing each group of 5% plate number (less than two sets can have two sets) consists of two rebar. Its diameter disc weight and plate shall be formulated by the supply and demand both sides talks things over.

B, the length of the allowable deviation: rebar according to scale the length of the delivery of the allowable deviation shall not be greater than + 50 mm.

C, bending and end: straight rebar bending change should not affect the normal use, the total curvature is not more than 40% of the total length of screw thread; Rebar ends should be cut integrity, local deformation shall not influence the use. [1]

HRB400 - need to detect project

Inspection items include: certificate number, rolling furnace number, grade, chemical composition (C, Si, Mn, P, V), tensile strength, yield point, elongation, relaxation rate, sectional area, product name, specification, quantity, delivery date, executive standard, receiving unit, etc. Only after inspection qualified can be for rebar, the acceptance of work.

- Q: Can steel rebars be used in the construction of museums and cultural centers?

- Yes, steel rebars can be used in the construction of museums and cultural centers. Steel rebars provide strength and durability, making them suitable for reinforcing concrete structures.

- Q: Can steel rebars be used in industrial construction?

- Yes, steel rebars are commonly used in industrial construction. They provide strength, durability, and structural support to reinforced concrete structures, making them ideal for heavy-duty applications in industrial settings.

- Q: What is the importance of proper anchoring of steel rebars in concrete?

- Proper anchoring of steel rebars in concrete is of utmost importance as it ensures structural integrity and enhances the overall strength and durability of the concrete structure. The anchoring process securely holds the rebars in place, preventing them from shifting or slipping under various loads and stresses. This, in turn, helps in maintaining the desired design strength, resisting cracking, and providing adequate reinforcement to withstand external forces such as earthquakes, wind, and other dynamic loads. In essence, proper anchoring of steel rebars is critical in ensuring the long-term stability and safety of concrete structures.

- Q: Difference between round bar and threaded steel in use

- Because steel for low alloy steel, its price is higher than that of low carbon steel, or construction units, design units, often on the general civil construction of the "practical" point of view, reduce the quality of the project, and the use of low carbon steel instead of rebar. For large engineering projects, often bribed "project inspector after" to replace "Choulianghuanzhu rib steel bar, reduce the construction cost.

- Q: Can steel rebars be used in the construction of water treatment plants?

- Yes, steel rebars can be used in the construction of water treatment plants. Steel rebars are commonly used in reinforced concrete structures, including water treatment plants, to provide strength and durability to the overall construction. The rebars help to reinforce the concrete and provide structural support, making them suitable for the rigorous demands and environmental conditions of water treatment plants.

- Q: What are the different types of tests conducted on steel rebars for quality assurance?

- There are several types of tests conducted on steel rebars for quality assurance. Some common tests include tensile testing, bend testing, impact testing, hardness testing, and chemical composition analysis. These tests help ensure that the rebars meet the required mechanical properties, dimensional tolerances, and chemical composition standards, ensuring their quality and suitability for various construction applications.

- Q: Can steel rebars be used in structures with high resistance to earthquakes?

- Yes, steel rebars can be used in structures with high resistance to earthquakes. Steel rebars are commonly used in reinforced concrete structures to enhance their strength and durability. In earthquake-prone areas, it is crucial to design and construct buildings that can withstand seismic forces. Steel rebars, when properly incorporated into the structural design, can help enhance the overall seismic performance of a building. Steel rebars provide several advantages in earthquake-resistant structures. Firstly, they increase the tensile strength of concrete, which is otherwise weak in tension. This reinforcement helps to prevent cracking and failure of the concrete during seismic events. Additionally, steel rebars can improve the ductility of the structure, allowing it to absorb and dissipate energy during an earthquake. This ductile behavior helps to minimize structural damage and ensures that the building remains stable and safe. Furthermore, steel rebars can be used in conjunction with other seismic design techniques to enhance the overall performance of the structure. For example, they can be combined with special concrete mixes, such as high-strength or fiber-reinforced concrete, to further improve the seismic resistance. Additionally, advanced structural systems like moment frames or shear walls can be integrated with steel rebars to provide even greater earthquake resistance. However, it is important to note that the earthquake resistance of a structure does not solely rely on the use of steel rebars. Proper design, construction techniques, and adherence to seismic building codes are also crucial factors. Engineers must consider various aspects such as the building's location, soil conditions, and expected seismic loads to ensure the structural integrity and safety of the building. In conclusion, steel rebars can be effectively used in structures with high resistance to earthquakes. Their inclusion in reinforced concrete structures enhances the tensile strength and ductility, enabling the building to withstand seismic forces. However, it is essential to implement comprehensive seismic design strategies and adhere to building codes to ensure the overall safety and performance of the structure.

- Q: How are steel rebars measured?

- Steel rebars are measured using a standardized system known as the "bar size number." This system assigns a numerical value to each rebar size, which corresponds to the diameter of the rebar. The diameter is measured in inches or millimeters, depending on the region or country. In the United States, the bar size number is used, which ranges from #3 to #18. The number indicates the diameter of the rebar in eighths of an inch. For instance, a #3 rebar has a diameter of 3/8 inch, while a #8 rebar has a diameter of 1 inch. Beyond #8, the diameter is measured in quarters of an inch. For example, a #11 rebar has a diameter of 1 1/8 inches, and a #18 rebar has a diameter of 2 1/4 inches. In metric countries, rebars are measured using millimeters. The diameter is typically rounded to the nearest millimeter. For instance, a 10 mm rebar is equivalent to a #3 rebar in the US, and a 25 mm rebar is equivalent to a #8 rebar. To measure the length of a rebar, a tape measure or ruler is used. The length is typically measured in feet or meters. Rebars are commonly available in lengths of 20 or 40 feet (6 or 12 meters), but they can also be cut to custom lengths as per project requirements. It is important to note that the measurement system may vary slightly in different regions or countries, so it is crucial to consult local standards and codes for accurate measurement guidelines.

- Q: How do steel rebars affect the overall strength of concrete structures?

- Steel rebars significantly contribute to the overall strength and durability of concrete structures. They are commonly used as reinforcement in concrete to enhance its tensile strength, which is the ability to withstand pulling or stretching forces. Concrete on its own is strong in compression but weak in tension. When external forces like bending or stretching are applied to the concrete, it tends to crack and fail. This is where steel rebars play a crucial role. By adding rebars to the concrete, the tensile strength of the structure is greatly improved. The rebars act as a strong skeleton within the concrete, providing resistance against tensile forces. When the concrete is subjected to tension, the rebars take up the load and distribute it evenly, preventing cracks from forming and enhancing the overall strength of the structure. This reinforcement also helps to limit the propagation of cracks, ensuring that the structure remains intact and stable even under substantial loads or adverse conditions. Moreover, steel rebars also enhance the structural integrity of concrete structures by improving their resistance to bending, shearing, and torsional forces. They increase the stiffness and stiffness modulus of the concrete, making it more resistant to deformation and enhancing its load carrying capacity. In addition to improving the structural strength, steel rebars also play a vital role in preventing corrosion of the concrete. They are made of corrosion-resistant materials, such as stainless steel or galvanized steel, which protects the concrete from moisture and other corrosive elements. This ensures the longevity and durability of the concrete structure. In conclusion, steel rebars significantly enhance the overall strength and durability of concrete structures by improving their tensile strength, resistance to bending and shearing forces, and preventing corrosion. They provide the necessary reinforcement to make the concrete capable of withstanding external forces, ensuring the safety and longevity of the structure.

- Q: What are the sizes available for steel rebars?

- Different construction needs can be accommodated by steel rebars, which are also known as reinforcing bars. Steel rebars are available in a range of sizes, typically from #3 to #18. Each size is assigned a corresponding number that represents the diameter of the bar in inches. For instance, a #3 rebar has a diameter of 3/8 inch, while a #18 rebar has a diameter of 2 1/4 inches. These sizes are universally standardized and widely utilized in construction projects around the world. The selection of a rebar size depends on various factors, including the structural requirements, load-bearing capacity, and specific engineering specifications of a particular project. The strength and load-bearing capacity of a rebar increase with its diameter. It should be noted that the availability of sizes may differ based on the region or country, as different standards and regulations may be followed. To determine the appropriate size of steel rebars to be used in a construction project, it is always advisable to consult local building codes and seek guidance from engineering professionals.

Send your message to us

Hot -rolled bar 400MPa

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords