Hot dip galvanized steel coil SS GRADE 340 quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 34562 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

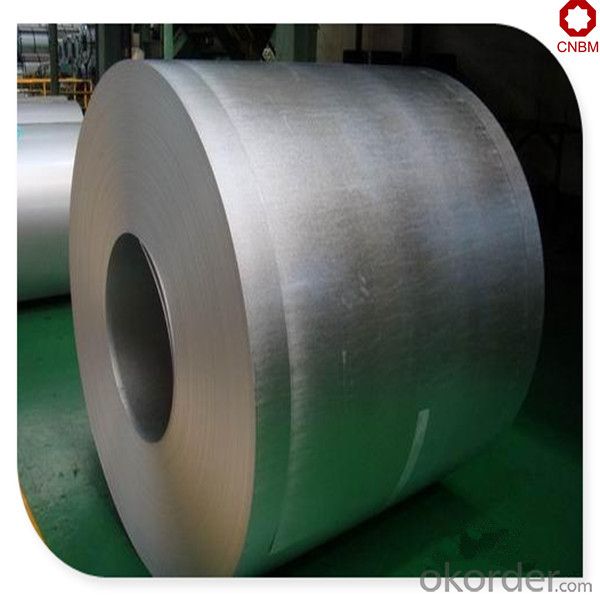

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

Pictures for stainless steel coil :

Standard and Grade :

Hot-dip galvanized steel coils | ||||

ASTM A653M-06a | EN10327:2004/ 10326:2004 | JISG 3302-2010 | AS-NZS 4534-2006 | |

Commercial quality | CS | DX51D+Z | SGCC | G1+Z |

Structure steel | SS GRADE 230 | S220GD+Z | SGC340 | G250+Z |

SS GRADE 255 | S250GD+Z | SGC400 | G330+Z | |

SS GRADE 275 | S280GD+Z | SGC440 | G350+Z | |

SS GRADE 340 | S320GD+Z | SGC490 | G450+Z | |

SS GRADE550 | S350GD+Z | SGC570 | G550+Z | |

S550GD+Z | G550+Z | |||

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: What are the dimensions of steel coils used in the metal furniture industry?

- Steel coils used in the metal furniture industry come in varying dimensions, depending on the specific requirements of each manufacturer. Commonly used dimensions include coil widths that range from 24 to 60 inches (61 to 152 cm) and coil diameters that range from 36 to 72 inches (91 to 183 cm). The thickness of the steel coils can also vary, typically falling between 0.020 and 0.250 inches (0.05 to 0.64 cm). These dimensions enable manufacturers to efficiently produce a variety of metal furniture, such as chairs, tables, and cabinets, by utilizing the steel coils as raw materials in their production processes.

- Q: What is the average turnaround time for processing steel coils?

- The average turnaround time for processing steel coils can vary depending on various factors such as the complexity of the process, size of the coils, and the efficiency of the manufacturing facility. However, in general, the average turnaround time for processing steel coils ranges from a few days to a few weeks.

- Q: How can the outer diameter and weight of steel coil be converted?

- To obtain the outer diameter of the steel coil is calculated according to the density of 7850, according to the density, in general, hot-rolled is 0. 96~0, 98, cold rolled, according to 0. 98~0. Ninety-nine

- Q: How long do steel coils last?

- The lifespan of steel coils can vary depending on various factors such as the quality of the steel, the conditions in which they are stored or used, and the specific application for which they are being used. Generally, high-quality steel coils can last for several years to several decades before showing signs of deterioration or wear. However, it is important to note that steel coils can be susceptible to corrosion if not properly maintained or protected from moisture or harsh environmental conditions. Therefore, regular inspection, maintenance, and appropriate storage or usage practices are crucial in maximizing the lifespan of steel coils.

- Q: What are the different types of welding methods used for steel coils?

- There are several different types of welding methods used for steel coils, including gas metal arc welding (GMAW), flux-cored arc welding (FCAW), shielded metal arc welding (SMAW), and submerged arc welding (SAW). Each method has its own advantages and is used based on the specific requirements of the project.

- Q: I know aluminum is lighter but I'm looking at a 01 bianchi grizzly mountain bike which is steel. I used to ride a specialized stumpjumper m4 which was aluminum. It was quite light so I don't know if I'll like a bit heavier bike but overall what is better from those who have had both?

- I've ridden steel, alum, Ti and carbon. I like 'em all. It all depends of craftsmanship and design IMHO. Really, a light steel frame is only about 1 to 1.5 lbs heavier than other super light frames. Steel has a rep for being heavy and most of that comes from being a heavier duty frame and being spec'ed with heavier parts. With that being said I have 2 alum and 1 carbon framed bikes now. I owned several steel bikes in my day, loved 'em too. I like light and if you're a weight weenie too you may not want a heavier bike regardless of material. The Stumpjumper is a sweet light bike. If the Grizzly is up to your specs give it a go. Thats how you experience life. Try something different. You'll like the feel of steel, as of the bike? Only you will know if you like it or not.

- Q: How do steel coils contribute to the automotive industry?

- Steel coils are a crucial component in the automotive industry as they are used to manufacture various parts of vehicles, including the body frame, doors, hoods, and chassis. The high strength and durability of steel coils make them ideal for enhancing the safety, structural integrity, and overall performance of automobiles. Additionally, steel coils are cost-effective, readily available, and can be easily formed into different shapes and sizes, making them an essential material in the production of cars and trucks.

- Q: for instance Cr-Ni steeldoes this refer to plated steel or a uniform mixture

- stainless steel is an alloy normally iron with additions of C, Mn, Ni, Cr, and Nb - amounts added depend on properties required. Corrosion resistance is due to a very thin but dense layer of chromium oxide which forms at the surface and prevents further attack. Ordinary steel on the other hand becomes coated with a porous layer of iron oxide(rust) through which the atmosphere can pass and cause further corrosion.

- Q: Can you weld copper or brass to steel?

- How To Weld Copper

- Q: What are the different types of coil recoiling machines?

- The different types of coil recoiling machines include manual coil recoilers, semi-automatic coil recoilers, and fully automatic coil recoilers.

Send your message to us

Hot dip galvanized steel coil SS GRADE 340 quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 34562 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords