Hot-Dip Galvanized Steel Coil Prime Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hot-Dip Galvanized Steel Coil Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process.

It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc.

The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust.

It is especially useful for countless outdoor and industrial applications.

2.Main Features of Hot-Dip Galvanized Steel Coil:

• Base material for countless outdoor and industrial applications

• High corrosion resistance

• High strength

• Good formability

• Rust- proof ability

• Good visual effect

3.Hot-Dip Galvanized Steel Coil Images

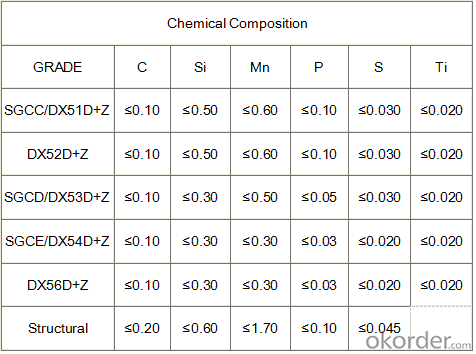

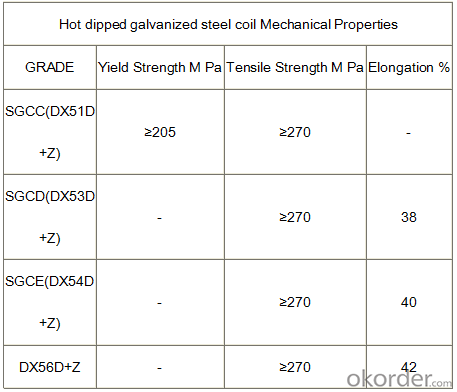

4. Hot-Dip Galvanized Steel Coil Specification

Operate Standard: ASTM A653M-04/JIS G3302/DIN EN10143/GBT 2518-2008

Grade : SGCD,SGCH, Q195,DX51D

Zinc coating :40-180g( as required)

Width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

Coil id:508mm/610mm

Coil weight: 4-10 MT(as required)

Surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

s

5.FAQ of Hot-Dip Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2) What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

3) How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Can a steel at 0.0055 of thickness still be powerful enough to bash skulls? As well as stop handgun cartridges or at least weaken them?You see, i had an idea of making a cylindrical Knuckles made from steel. By my dimensions, 5in diameter, 12 inch h1 and 15 in h2. Half-Sphere: a sphere that is cut in half for the dome at the fist:( [ pi x ( d ^ 3) ] / 6 ) / 2Cylinder

- I don't follow your calculations. It seems to me that the piece you show could be made from .01 steel and still be less than a pound. Also, it is hard to get steel thinner than .015 because anything thinner is not very useful. If you made it out of .015 steel and used a high strength steel, it might be useful. You wouldn't be bashing any skulls, but with some spikes on the end, it could do some damage, and protect against knives or other hand weapons. You also won't get any bullet resistance out of anything that thin. If you want to bash skulls and deflect bullets, you have to get up to at least .10 and several pounds. Any weight on your hands slows down the speed of your punch, but this is compensated for by the increased energy of impact carried by the extra mass. Also, having something hard to protect your hands allows for harder hits and more damage to the opponent. An interesting idea, but it would take some testing to figure out the optimum configuration. One problem I see is that it completely encloses the hand, making it impossible to use the hand for anything else. So you would have to put it on and take it off a lot, and there would be cases where you wouldn't be able to put it on when you needed it. For that reason, I would not wear two at one time. I would make it heavier and wear it on one hand for bashing skulls and deflecting weapons, and keep the other hand free for other things.

- Q: I have a Nike SQ Sumo 21 degree and it is a steel shaft. I hit the ball very high with this club and I lose distance. I don't hit any of my other clubs high it's just this one. Is it because of the steel shaft or is it the club? Help please.

- if you are a good player they say steel shaft is better. more consistent. I prefer graphite its lighter and I can flip my wrists easier.

- Q: How can I tell the wear resistance, strength, ect from the name of the steel?how could I tell the difference between 420 and 440 steel. what does the HC in 420 HC steel mean? what do the numbers and letters in s30v steel mean?

- If your question implies how to tell the differences just by looking at the actual knife then I'd say there is no real way to do that. Just about all high carbon steel's look alike. You should be able to tell the difference between a stainless steel, but which one is anybodies guess, and a carbon steel however.

- Q: What are the advantages of using steel coils over other materials?

- There are several advantages of using steel coils over other materials. Firstly, steel is highly durable and has a long lifespan, making it ideal for various applications. Secondly, steel coils have excellent strength and can withstand heavy loads and extreme weather conditions. Thirdly, steel is recyclable and environmentally friendly, ensuring sustainability. Additionally, steel coils provide superior corrosion resistance, reducing maintenance costs. Lastly, steel offers versatility in terms of customization, allowing for various shapes, sizes, and thicknesses to meet specific requirements.

- Q: Steel or stainless steel

- Steel often has impurities that can generate fumes, which cause a fever identical to smoke inhalation. You always need to be concerned about what you are breathing around hot metal.

- Q: How long can steel coils be stored?

- Steel coils can be stored for an extended period if proper storage conditions are maintained. The duration of storage depends on factors such as coil quality, environmental conditions, and any specific storage requirements determined by the manufacturer.

- Q: Can steel coils be used in structural applications?

- Yes, steel coils can be used in structural applications. Steel coils are often processed into various shapes and forms, such as beams, columns, or plates, to provide structural support and strength in construction projects. The use of steel coils ensures durability, load-bearing capacity, and resistance to deformation, making them suitable for structural applications in buildings, bridges, and other infrastructure projects.

- Q: Obviously this is an easy question for anyone who works with metal. However, I am currently writing a book and had an idea that had to do with these two metals. Is it possible for gold to be folded into steel while it is being forged? Do 3-metal alloys exist? If this is not possible with current metal-working techniques and technology, what would be needed to make it possible? And finally, what exactly would the mixing of these two yield? A weak metal? A brittle metal? How would it compare to iron or gunmetal? If you have no idea, please offer speculations. Thank you!

- Well put it this way you cant gold steel but you can steel gold Kidding but seriously you can but ther would be no point the steel would be weaker and gold is expensive

- Q: How do steel coil manufacturers minimize waste and maximize efficiency?

- Combining advanced technology, process optimization, and waste management practices allows steel coil manufacturers to minimize waste and maximize efficiency. One effective method is to employ advanced automation and control systems during production. These systems can monitor and adjust parameters like temperature, pressure, and speed to ensure optimal operation. By closely monitoring and controlling these factors, manufacturers can reduce defects and errors, thus minimizing waste. Another approach is to adopt lean manufacturing principles, which involve eliminating non-value-adding activities and streamlining the production process. By analyzing the entire workflow, manufacturers can identify areas for improvement, such as reducing setup times, eliminating bottlenecks, and optimizing material flow. This results in a more efficient and streamlined production process, reducing waste and increasing efficiency. Additionally, effective waste management practices can be implemented. This includes proper handling and disposal of waste materials, as well as implementing recycling programs. By separating and recycling materials like scrap metal, manufacturers can minimize waste generation and reduce environmental impact. Collaborating with recycling companies ensures proper management and recycling of waste materials. In conclusion, steel coil manufacturers can achieve waste reduction and efficiency maximization by utilizing advanced technology, implementing lean manufacturing principles, and adopting effective waste management practices. Continuously striving for improvement and optimization in processes enables manufacturers to reduce waste, increase productivity, and ultimately achieve higher levels of efficiency.

- Q: What are the different coil winding methods used for steel coils?

- The different coil winding methods used for steel coils include cross-winding, helical winding, and layer winding. Cross-winding involves winding the steel coil in a crisscross pattern to ensure even distribution of the material. Helical winding involves winding the steel coil in a spiral pattern, which provides strength and stability to the coil. Layer winding involves winding the steel coil in layers, with each layer placed on top of the previous one, ensuring efficient use of space and easy unwinding of the coil.

Send your message to us

Hot-Dip Galvanized Steel Coil Prime Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords