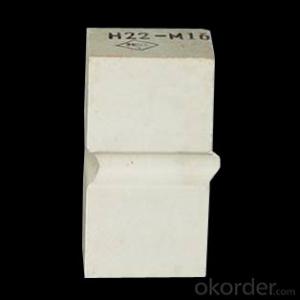

Silica Insulation Brick for Hot Blast Furnace Applied Refractory

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

refractory silica brick

ISO9001

one of the largesr manufacture

factory price

fast delivery

Hot blast furnace&glass furnace applied refractory silica brick

Introduction of refractory silica brick

Refractory silica brick is dense shaped refractory material and the main materials is SiO2.

Features of refractory silica brick

1) Silicon oxide is above 95%.

2) Good acid glass furnace erosion resistance.

3) High softening point with temperature.

4) No shrink in burn repeatedly.

5) Temperature of refractoriness under load is above 1650º C

Stable Capability, High Quality, Excellent Service, Competitive price is the most important advantage of our products.

Our capacity:

We have 2 tunnel kiln with 168meters length and 25 sets of compressing machine with 300-500tons capacity. with the annual capacity more than 50,000tons .

Application of refractory silica brick

They are widely used for hot blast furnace,coke oven,glass furnace.The products can be made according with the customers' requirement.

Physical and chemican index:

| MARK | JG-95 |

|---|---|

| Bottom, WallOthers | |

| SiO2,% ≥ | 95 |

| 0.2Mpa Refractoriness Under Load , °C ≥ | crystal silica :1650 cementation silica (ShanXi province): 1620 |

Permanent Linear Change after heating(%), 1450°C×2h(P.L.C) | +0.2 0 |

| Apparent Porosity(A.P),% ≤ | 22(23)24 |

| Cold Crushing Strength(C.C.S), Mpa ≥ | 3025 |

| Real Density g/m3 ≤ | 2.342.35 |

| Rate Of Thermal Expansion (R.T.E)(1000°C),% ≤ | 1.281.30 |

| Residual Quartz (%) ≤ | 1 |

- Q: Physical solid waste disposal

- Reduce crack production and improve yield. The amount of addition is related to the shape and weight of the brick. The bricks can be added to 20% weight less than 25kg; bricks above 25kg can be added to 30%; for the specific type of brick can be added 30%. into waste silica brick should pay attention to this problem

- Q: What is acid refractory?

- Acid refractory material usually refers to refractories with SiO2 content greater than 93%. Its main characteristic is that it can resist acid slag corrosion at high temperature, but it is easy to react with alkaline slag.

- Q: Glass kiln brick for physical and chemical indicators?

- Glass kiln with high quality silica brick products according to the standard JC/T615-1996, the single brick is divided into 3 grades: XBG-96, ZBG-96, DBG-96.

- Q: Which material is good for furnace refractory?

- Neutral refractory is mainly composed of alumina, chromium oxide or carbon. Corundum products containing more than 95% of alumina are a kind of high quality refractory materials with a wide range of uses. Chrome brick with chromium oxide as its main component has good corrosion resistance, but its thermal shock resistance is poor, and its deformation temperature is lower at high temperature. Carbon refractories with carbon bricks, graphite and silicon carbide products, low coefficient of thermal expansion, high thermal conductivity, good thermal shock resistance, high strength, resistance to acid and salt corrosion, especially weak acid has good resistance, without wetting of the metal and slag, light. It is widely used as lining material of high temperature, and also used as lining of autoclave in petroleum and chemical industry.

- Q: How to judge the quality of brick, clay brick, high alumina brick furnace from the appearance?

- Mainly depends on the color and density of brick. Another black clay brick and brick with iron oxide formation and how much the size of bricks

- Q: Can iron oxide be used as refractory material?

- Iron oxide can not be used as refractory material, but it can be used as refractory additive. Iron oxide can be used as pigment

- Q: The high thermal conductivity of silica brick and traditional brick what is the difference?

- Tridymite content high thermal conductivity silica brick is 70%, tridymite content of traditional brick is 60%, tridymite content high thermal conductivity of silica brick than tridymite high content of 10% traditional brick,

- Q: The chemical composition of silica brick and its physicochemical index?

- The physicochemical index of silica brick:Turn left to |

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Clay brick features good thermal shock resistance and low price, but high temperature performance is not well integrated, and the long-term use temperature is not higher than 1300 degrees. It is widely used in low temperature parts of various kilns.

- Q: Physical solid waste disposal

- Too much addition will reduce the refractory and mechanical strength, increase porosity, so the amount of waste brick should not be too much.

Send your message to us

Silica Insulation Brick for Hot Blast Furnace Applied Refractory

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords