High Tensile Strength Fiberglass Rail Track Reinforcement Geogrids with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

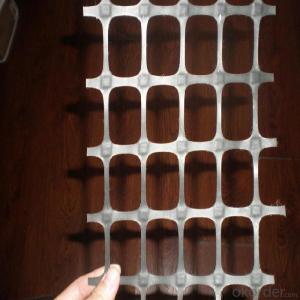

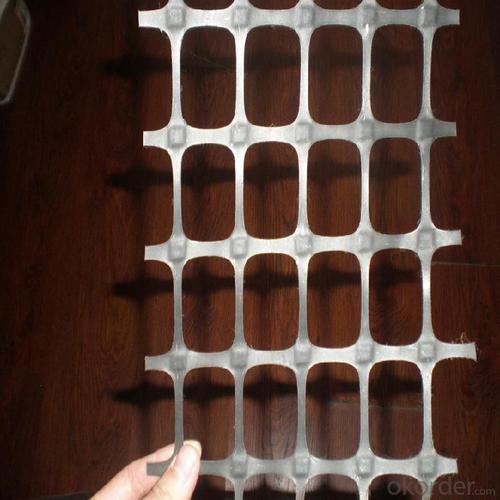

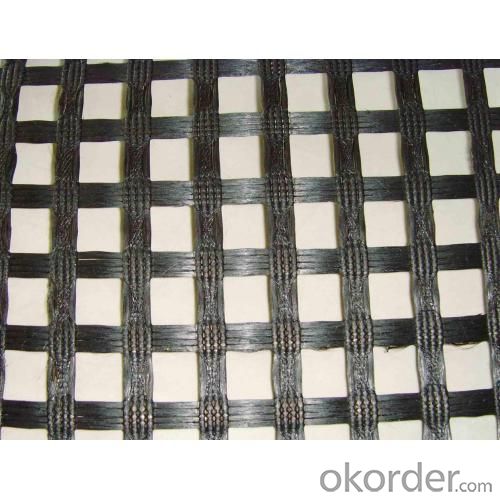

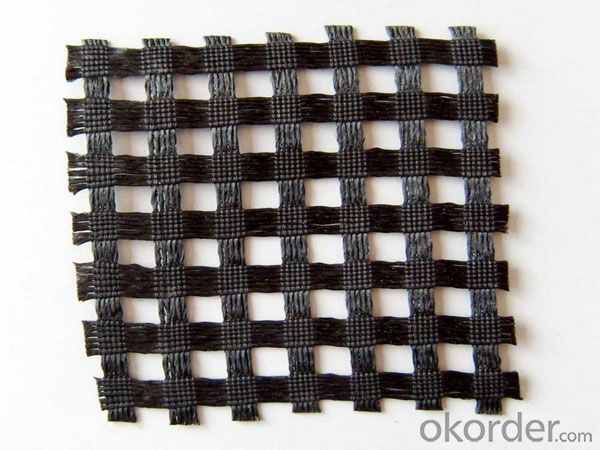

Structure of High Tensile Strength Fiberglass Geogrid Description:

High Tensile Strength Fiberglass Geogrid is a kind of reinforcement product, Both warp and weft directions are high tensile strength and low elongation. It can be used in the construction o railway, highway, bridge, wharf, etc., which require firm-quality construction materials for security purpose. Therefore basalt fiber geogrid is an ideal material for construction.

Main Features of High Tensile Strength Fiberglass Geogrid:

High strength, high modulus and low elongation.

Aging resistance and high tensile strength.

Pre-designed and easily combing with gravel and soil

Could replace steel-plastic geogrid in coal mine.

High Tensile Strength Fiberglass Geogrid Images

High Tensile Strength Fiberglass Geogrid Specification:

Index Properties | Units | MD Values | XMD Values |

Aperture Dimensions | mm(in) | 25(1.0) | 33(1.3) |

Minimun Rib Thickness | mm(in) | 1.27(0.05) | 1.27(0.05) |

Tensile Strength @2% Strain | KN/m(lb/ft) | 6.0(410) | 9.0(620) |

Tensile Strength @5% Strain | KN/m(lb/ft) | 11.8(810) | 19.6(1,340) |

Ultimate Tensile Strength | KN/m(lb/ft) | 19.2(1,310) | 28.8(1,970) |

Junction Efficiency | % | 93 | |

Flexural Stiffness | Mg-cm | 750,000 | |

Aperture Stability | m-N/deg | 0.65 | |

Resistance to Installation Damage | %SC/%SW/%GP | 95/93/90 | |

Resistance to Long Term Degradation | % | 100 | |

Resistance to UV Degradation | % | 100 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: What are the specifications of unidirectional geogrid?

- Depending on the tension there are TGDG30KN TGDG40KN TGDG60KN TGDG80KN TGDG100KN TGDG110KN TGDG120KN TGDG150KN TGDG200KN up to TGDG260KN TGDG90KN (TGDG50KN)

- Q: Are geogrids suitable for use in soil reinforcement for wind turbine foundations?

- Yes, geogrids are suitable for use in soil reinforcement for wind turbine foundations. Geogrids provide effective reinforcement by increasing soil stability, reducing settlement, and improving load distribution. They enhance the overall performance and longevity of wind turbine foundations, making them a suitable choice for such applications.

- Q: Are geogrids suitable for use in expansive soil conditions?

- Yes, geogrids are suitable for use in expansive soil conditions. Geogrids are commonly used in such conditions to improve the stability and strength of the soil. They help control soil movement, reduce cracking, and prevent damage to structures caused by expansive soils. Geogrids provide reinforcement and help distribute loads more evenly, making them an effective solution in expansive soil conditions.

- Q: Can geogrids be used in stabilization of riverbanks?

- Yes, geogrids can be used in the stabilization of riverbanks. Geogrids are commonly utilized in civil engineering and geotechnical applications to reinforce soil and prevent erosion. By providing additional strength and stability to the riverbank, geogrids help to prevent soil erosion, reduce sedimentation, and protect against damage caused by water flow, ultimately enhancing the stability and longevity of the riverbank.

- Q: Can geogrids be used in temporary retaining structures?

- Yes, geogrids can be used in temporary retaining structures. Geogrids are commonly used in retaining walls and slopes to provide reinforcement and stability. They help distribute the load, prevent soil erosion, and enhance the overall strength of the structure. Therefore, they can be an effective solution for temporary retaining structures as well.

- Q: How many square meters of geogrid?

- Geogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosynthetics. Geogrid is often used as reinforcement of reinforced soil structure or composite material. The geogrid is composed of plastic geogrid, steel plastic geogrid, fiberglass geogrid and polyester warp knitted polyester geogrid

- Q: How do geogrids enhance the stability of embankments?

- Geogrids enhance the stability of embankments by providing reinforcement and increasing the load-bearing capacity of the soil. They act as a structural element by distributing the applied loads more evenly, reducing the risk of slope failure and settlement. Additionally, geogrids increase the shear strength of the soil, preventing lateral movement and erosion, thereby improving the overall stability of the embankment.

- Q: Do you need a production license for the production of geogrid?

- Main production, geotextile, geogrid, geomembrane, bentonite waterproof blanket,

- Q: Are geogrids suitable for use in ground reinforcement for solar farms?

- Yes, geogrids are suitable for use in ground reinforcement for solar farms. Geogrids offer excellent soil stabilization and reinforcement properties, enhancing the load-bearing capacity of the ground and preventing soil erosion. They can effectively distribute the weight of solar panels and equipment, reducing the risk of settlement and ensuring long-term stability. Additionally, geogrids are easy to install, cost-effective, and provide long-lasting performance, making them a suitable choice for ground reinforcement in solar farms.

- Q: Geogrid test items: what is the point of the joint point of penetration

- The conventional test items of geogrid are tensile strength, elongation, and welding point peeling force.

Send your message to us

High Tensile Strength Fiberglass Rail Track Reinforcement Geogrids with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords