Silicone Impregnated High Temperature Resistance Silica Fiber Cloth

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Image:

Product Description & Application:

Silica fiberglass cloth is one high-temperature inorganic fiber with the molten temperature nearly 1700 degree Celsius, and the work for a long time at 900 degree Celsius.

Application:

Widely used as heat resistant and ablationresistasant material for rocket,missile and space vehicle;

High-temperature resistant,thermal insulation,refractory material;

Dust collect for high temperature gas;

Liquid filtration;Sound absorbing and thermal insulation for vehicle,motor bicycle;The thermal insulation protective materials for molten liquid filtration.

Product Capability:

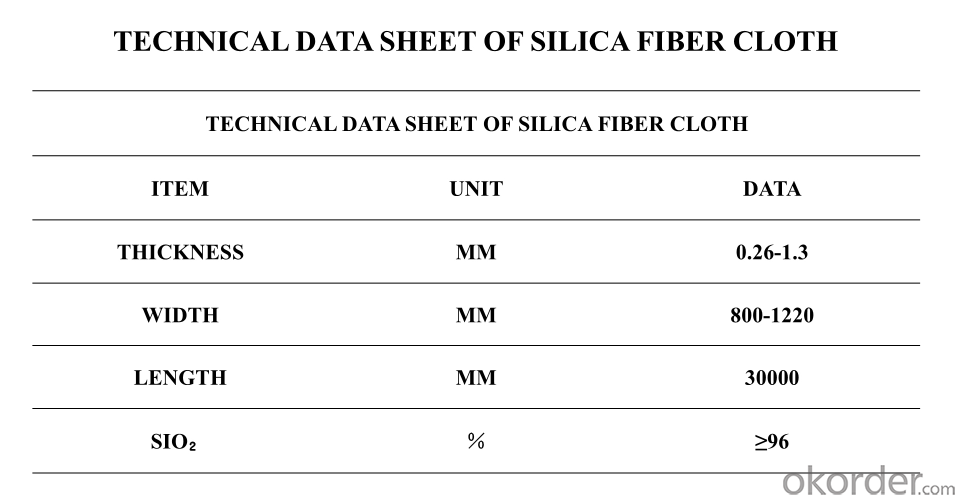

SiO2>=96%;

High temperature resistant,higher thermal insulation,low thermal conductivity;

Thermal stability and chemical stability;

High strength and easy to manufacture;

Nontoxic and harmless to the environment.

Data Sheet:

Fiberglass products:

Fiberglass is a kind of long fiber. It has the advantage of high tensile strength, low thermal conductivity, corrosion resistance and good insulation.The working temperature ranges from 200-1000 degree Celsius. Main products: Fiberglass texturized yarn, cloth, tape, rope, sleeve,mesh,filter cap,friction thread (piece) and fiber netting,composite yarn etc.

- Q: Can fiberglass fabric be used for heat-resistant sleeves?

- Indeed, heat-resistant sleeves can be made using fiberglass fabric. The properties of fiberglass fabric make it an excellent choice for heat-resistant applications. It can withstand high temperatures without melting or deforming, thanks to its outstanding heat-resistant capabilities. With a high melting point and resistance to fire, fiberglass fabric is the ideal material to protect against heat. Industries that require heat protection, such as welding, metalworking, and firefighting, often favor fiberglass fabric for its ability to insulate and create a barrier between the user and hot surfaces. Moreover, fiberglass fabric offers additional benefits, including being lightweight, durable, and flexible. These qualities ensure ease of movement and comfort while providing effective heat protection.

- Q: Is fiberglass fabric resistant to chemicals used in food processing?

- Yes, fiberglass fabric is generally resistant to the chemicals used in food processing. It is designed to withstand a wide range of chemicals, making it suitable for use in various industries, including food processing.

- Q: How is fiberglass fabric painted?

- Fiberglass fabric is typically painted using a spray gun or brush application with a compatible paint or coating specifically formulated for use on fiberglass materials. The fabric should be clean, dry, and free from any contaminants before applying the paint. It is recommended to apply several thin coats to achieve an even and durable finish.

- Q: Can fiberglass fabric be used for reinforcement in composite materials?

- Yes, fiberglass fabric can be used for reinforcement in composite materials. Fiberglass is a commonly used material in composites due to its high strength-to-weight ratio, corrosion resistance, and durability. The fabric is typically made from fine fibers of glass woven together, providing excellent tensile strength and flexibility. When combined with a matrix material such as epoxy resin, the fiberglass fabric reinforces the composite structure, enhancing its mechanical properties. This makes fiberglass fabric an ideal choice for industries such as aerospace, automotive, construction, and marine, where lightweight, strong, and durable materials are required.

- Q: Can fiberglass fabric be used as a heat shield?

- Indeed, fiberglass fabric is capable of functioning as a heat shield. This material, renowned for its exceptional resistance to heat, is commonly employed in scenarios where thermal insulation is necessary. With its remarkable ability to resist fire, fiberglass can endure extreme temperatures without undergoing any deformation or melting. In various industries such as aerospace, automotive, and construction, fiberglass fabric is frequently utilized as a heat shield. Its lightweight nature and flexibility allow for easy molding or shaping to accommodate diverse surfaces. Furthermore, fiberglass fabric possesses low thermal conductivity, effectively impeding the transfer of heat. In summary, fiberglass fabric is a dependable option for a heat shield due to its outstanding heat resistance, adaptability, and longevity.

- Q: Is fiberglass fabric suitable for outdoor use?

- Yes, fiberglass fabric is suitable for outdoor use. Fiberglass is known for its exceptional durability and resistance to various environmental factors such as sunlight, moisture, and temperature fluctuations. It is also highly resistant to chemicals, making it suitable for outdoor applications where exposure to harsh weather conditions or chemicals is expected. Additionally, fiberglass fabric is lightweight, flexible, and easy to handle, making it an ideal choice for outdoor products such as awnings, canopies, boat covers, and outdoor furniture upholstery. Its heat resistance and fire-retardant properties also make it a safe option for outdoor use. Overall, fiberglass fabric is a reliable and widely used material for outdoor applications due to its strength, durability, and resistance to various outdoor elements.

- Q: How does fiberglass fabric perform in abrasive environments?

- Fiberglass fabric is known for its exceptional performance in abrasive environments. Its unique composition and construction make it highly resistant to wear and tear caused by abrasion. Firstly, fiberglass fabric is made from fine strands of glass fibers that are woven together to create a strong and durable material. These glass fibers possess excellent resistance to abrasion, making the fabric highly resilient and capable of withstanding the repetitive rubbing or scraping actions often encountered in abrasive environments. Additionally, fiberglass fabric is commonly coated with a protective layer or finish to further enhance its resistance to abrasion. This coating acts as a barrier, preventing the abrasive particles from directly coming into contact with the fabric. As a result, the fabric is able to maintain its integrity and performance over time, even in extremely abrasive conditions. Moreover, fiberglass fabric exhibits low friction properties, which is beneficial in abrasive environments. This low friction characteristic reduces the chances of the fabric being abraded or worn down due to constant rubbing or contact with rough surfaces. It also helps to minimize the generation of heat, which is often associated with abrasion, thereby contributing to the fabric's longevity and performance. Overall, fiberglass fabric is an excellent choice for applications in abrasive environments. Its inherent resistance to abrasion, coupled with protective coatings and low friction properties, ensures that the fabric can withstand the challenges posed by abrasive conditions, providing long-lasting performance and durability.

- Q: How is fiberglass fabric used in the production of heat shields?

- Due to its exceptional thermal insulation properties, fiberglass fabric is commonly utilized in the production of heat shields. These shields are specifically designed to safeguard different components or structures from heat damage or excessive temperatures. Acting as a barrier between the heat source and the protected area, fiberglass fabric effectively prevents the transfer of heat, thereby reducing the risk of harm. The use of fiberglass fabric in heat shields offers several benefits. Firstly, fiberglass is a non-combustible material, meaning it does not burn or emit harmful gases when exposed to high temperatures. This characteristic is of utmost importance in heat shield applications as it ensures the fabric remains intact and efficient even in extreme heat conditions. Moreover, fiberglass fabric demonstrates excellent thermal insulation properties. Possessing a low thermal conductivity, it efficiently inhibits the conduction of heat. This feature enables the fabric to effectively trap and slow down the transfer of heat, effectively preventing it from reaching the protected area. Additionally, fiberglass fabric is highly flexible and lightweight, facilitating its integration into various heat shield designs. It can be easily molded or shaped to suit different applications, guaranteeing a proper and secure fit. Furthermore, its lightweight nature minimizes the overall weight of the heat shield, presenting a particular advantage in weight-sensitive industries like aerospace. Furthermore, fiberglass fabric exhibits resistance to various chemicals, moisture, and corrosion. This resistance renders it suitable for deployment in diverse environments and industries, including automotive, aerospace, industrial, and marine applications. In conclusion, the utilization of fiberglass fabric in the production of heat shields is attributed to its non-combustible nature, exceptional thermal insulation properties, flexibility, lightweight design, and resistance to chemicals and moisture. Its incorporation into heat shield manufacturing ensures the effective protection of components or structures from heat damage, rendering it an invaluable material in this particular application.

- Q: Is fiberglass fabric resistant to high temperatures?

- Yes, fiberglass fabric is highly resistant to high temperatures. It can withstand temperatures up to 1000 degrees Fahrenheit without melting or degrading, making it suitable for various applications that involve exposure to extreme heat.

- Q: What are the cracks between the brick wall and the beam column, the cracks between the planks and the cracks in the plasterboard?

- Cracks in masonry and beams and columns can be nailed at the junction of steel mesh or glass fiber cloth, and then plastering;

Send your message to us

Silicone Impregnated High Temperature Resistance Silica Fiber Cloth

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords