Geogride Stragrip Sg-150 High Strength Warp Knitting Polyester Geogrids for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Warp Knitting Polyester Geogrids

Warp Knitting Polyester Geogrids is with polypropylene, high density polyethylene as raw materials, made by special extrusion, two-way stretch.It Can reduce structural fill, uniform load distribution, and has high two-way tensile modulus and tensile strength, high mechanical damage ability, endurance ability.

Main Features of the Warp Knitting Polyester Geogrids

High quality asphalt coation

Light weight, high tensile, corrosion resistance

Road maintenance and reinforcement

Packaging & Delivery

| Packaging Details: | PP bags or PE film. Or Packed as customers' requests. |

| Delivery Detail: | 10-20days after the contract is effective |

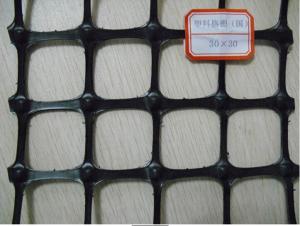

Warp Knitting Polyester Geogrids Images

Warp Knitting Polyester Geogrids Specification

Converting old cement concrete road into composite road.

Restraining reflection cracking caused by block shrinkage.

Preventing and controlling the cracking caused by new and old combination and uneven settlement.

Strength: 20x20kn/m--600x600kn/m, such as :60/30, 60/60, 80/30, 120/30, 150/30, 200/30 etc..

Reinforcement of soft soil foundation and overall strength of roadbed

| Item | Tensile strength(KN/m) | Tensile strength at 2% elongation | Tensile strength at 5% elongation | Nomianal elongation | Products in the range of coal mine | ||

| TGSG15-15 | ≥15.0 | ≥5.0 | ≥7.0 | ≤15.0/13.0 | Fire out time from outer flam(s) | Surface resistivity | |

| TGSG20-20 | ≥20.0 | ≥7.0 | ≥14.0 | ≤3 | <1×109 | ||

| TGSG25-25 | ≥25.0 | ≥9.0 | ≥17.0 | ||||

| TGSG30-30 | ≥30.0 | ≥10.5 | ≥21.0 | ||||

| TGSG35-35 | ≥35.0 | ≥12.0 | ≥24.0 | ||||

| TGSG40-40 | ≥40.0 | ≥14.0 | ≥28.0 | ||||

| TGSG45-45 | ≥45.0 | ≥16.0 | ≥32.0 | ||||

| TGSG50-50 | ≥50.0 | ≥17.5 | ≥35.0 | ||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q: How about your company?

A:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q.Does your products have good qualitity?

A:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q:How long can we receive the products after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Bi directional plastic geogrid is suitable for engineering

- Wharf cargo yard and other permanent bearing foundation reinforcement.Supply geogrid.

- Q: Can geogrids be used in ground stabilization for telecommunications infrastructure?

- Yes, geogrids can be used in ground stabilization for telecommunications infrastructure. Geogrids are commonly used to reinforce soil and provide stability to various types of infrastructure, including telecommunications installations. They can effectively distribute loads, prevent soil erosion, and enhance the overall strength and stability of the ground.

- Q: Can geogrids be used in reinforcement of mechanically stabilized earth bridge abutments on collapsible soils?

- Yes, geogrids can be effectively used in the reinforcement of mechanically stabilized earth (MSE) bridge abutments on collapsible soils. Geogrids are commonly used in MSE structures to provide additional strength and stability by improving soil retention and preventing lateral movement. In the case of collapsible soils, geogrids can help distribute the applied loads more evenly, reducing the risk of soil settlement and potential bridge abutment failure. Therefore, incorporating geogrids in the reinforcement of MSE bridge abutments on collapsible soils can be a reliable and efficient solution.

- Q: Which instrument is used to measure the permeability of geotextiles?

- . The warp knitted composite geotextile is a new kind of geotextile material, which is made of glass fiber (or synthetic fiber) as the reinforcing material. The geotextile is a kind of impervious material, which is made of plastic film as impervious material and non-woven fabric. It is a kind of nonwoven and industrial cloth. It is a kind of polyester staple fiber, which is made of 6-12 denier denier fiber with a length of 54-64mm. Through the production of non-woven production equipment, carding, messy (short fiber intertwined with each other), laying nets (standardized entanglement fixation), acupuncture and other production processes are made of cloth

- Q: Are geogrids suitable for use in soil reinforcement for coastal protection structures?

- Yes, geogrids are suitable for use in soil reinforcement for coastal protection structures. Geogrids are commonly used in such applications as they provide excellent reinforcement to the soil, improving its stability and resistance against erosion caused by waves and tides. They offer high tensile strength, durability, and resistance to harsh environmental conditions. Additionally, geogrids can be easily installed and integrated into various coastal protection systems, making them an effective solution for reinforcing soil in coastal areas.

- Q: Can geogrids be used in floating road construction?

- Yes, geogrids can be used in floating road construction. Geogrids are often used to reinforce and stabilize the subgrade in road construction projects, including floating roads. They provide additional strength and stability to the road structure, allowing it to withstand heavy loads and prevent deformation.

- Q: What are the differences between geogrids and geotubes?

- Geogrids and geotubes are both geosynthetic materials used in civil engineering and environmental applications, but they have distinct differences. Geogrids are typically made of polymer materials and are designed to provide soil reinforcement and stabilization. They have a grid-like structure with open spaces and are used to improve the strength and bearing capacity of soils. Geogrids are commonly used in road construction, retaining walls, and slope stabilization projects. On the other hand, geotubes are large, tubular containers made from high-strength woven or non-woven geotextile fabrics. They are used for shoreline protection, coastal erosion control, and dewatering applications. Geotubes are filled with sediment, sludge, or other materials and then dewatered, allowing water to escape while retaining the solid contents. They are often used in coastal engineering projects to create or restore beaches, control erosion, and contain contaminants. In summary, while geogrids are used for soil reinforcement and stabilization, geotubes are used for dewatering and containment purposes in coastal and environmental applications.

- Q: What are the design considerations for geogrid installation?

- Some key design considerations for geogrid installation include selecting the appropriate geogrid material and strength, determining the proper placement depth and orientation, considering soil characteristics and compaction requirements, ensuring adequate anchoring and connection methods, and accounting for potential loads and stresses that the geogrid will need to withstand. Additionally, factors such as site conditions, environmental factors, and project specifications should also be taken into account during the design process.

- Q: What is the meaning of 400g geotextiles /100g woven fabric

- Should be a layer of woven cloth PE film and a layer of geotextile. PE membrane and geotextile 400g

- Q: What is the meaning of 80 in geogrid TGSG80

- Hello, this is a two-way stretch polypropylene geogrid.

Send your message to us

Geogride Stragrip Sg-150 High Strength Warp Knitting Polyester Geogrids for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords