High Quality WPC Co-extrusion Composite Decking Past CE

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Features of the WPC Decking:

1. Recyclable, Eco-friendly, saving forest resources

2. With the look of the natural wood, but less timber problems

3. Moisture/water resistant, less rotten, proven under salt water condition

4. Barefoot friendly, anti-slip, less cracking, less warping

5. Requires no painting, no glue, low maintenance effort

6. Weather resistant, suitable from minus - 40 to 60 centigrade degree

7. Termites and insects resistant, and moldy-proof

8. Easy to install and clean

Specification of the WPC Decking:

component | 30%HDPE(Grade A Recycled HDPE) 60%bamboo/wood fiber component 10%chemical additives New material capped outside |

Size | 140X20mm |

Design | Solid decking |

Length | 2.9m/pc standard length, also from your required |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE,Walnut,graystone,Cedar,Rosewood) and we can adjust the new color according to the order requirement |

Cerfiticate | ISO9001, ISO14001, CE, FSC Certificate,"REACH"Test Reports by SGS; Intertek Test Report by ASTM standard..etc. |

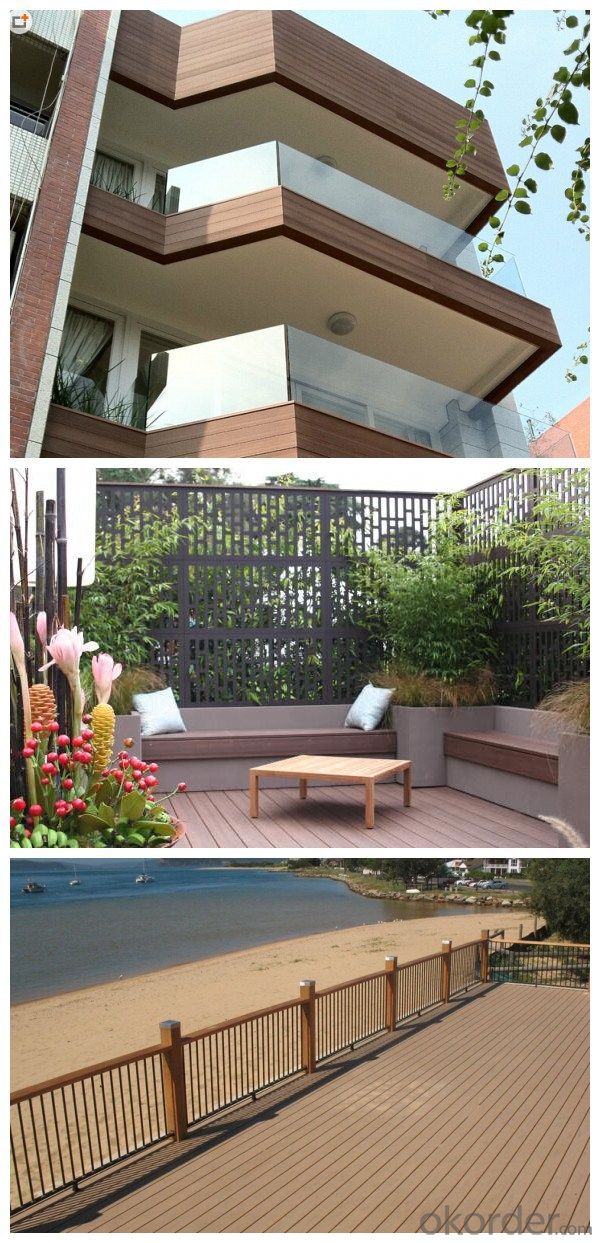

Images of Co-extrusion WPC Decking:

FAQ of Co-extrusion WPC Decking :

1. Available Colours?

5 regular colors to choose ( IPE,Walnut,graystone,Cedar,Rosewood )

2. How to Install?

3.Treatment for Option

- Q: Is it good for solid wood flooring? Tangled. The

- On the foot feel is certainly solid wood flooring is better, but the solid wood flooring care more trouble, especially for the use of the North, easy to crack. Solid wood flooring is also called multi-layer solid wood flooring, is made of solid wood cut into pieces and then staggered. There is a little sense of foot, but the multi-layer solid wood can not be polished refurbished, the surface of the veneer case of hard objects is extremely easy to damage, and solid wood flooring can be polished several times after re-painting, renovation and the new floor is the same, and Good wood flooring is a certain value of the property. The price gap between the large, solid wood composite in about 180 to 300, a little better solid wood flooring in more than 300 to a few thousand dollars. In general, is to see your personal preferences and economic strength.

- Q: Solid wood, polymer materials and veneer baseboard which is more suitable for some? What are the advantages and disadvantages? Thank you more

- Solid wood baseboard, basically 15 / m can win, without labor costs ~ and I feel the floor solid wood is not good ~

- Q: Strengthen the composite floor is thin or good thick, and now the market has 8mm9mm10mm12mm, 12mm more

- It depends on your needs, thin more suitable for warm, thick feet will feel better.

- Q: New home decoration! For the floor is not very understand!

- Environmental protection is certainly solid wood is good, the cost of materials are also tattoo dung on the pedal irony is a solid wood is good but the composite floor also has its advantages, such as can be made scratch-resistant, and solid wood flooring is more need to carefully maintenance

- Q: To warm on the floor can shop wood? What is the ground? To warm on the floor can shop wood? What is the ground? More

- Of course can be paved. It is also cool in the summer.

- Q: How to stitch the composite floor, I put the two sides of the long side of the board again how to fight is not fight it? And later the two boards on the top of the interface alignment fight, the results can be flattened can be inserted into the half of the damage Geng indignation of the siege of the bargain to fall into the next can not get into the next, may be the board Too long in this way wrong, please experts to help you! Xiexie problem added: more

- Splicing the floor is a complicated process, different colors and patterns veneer type stitching, elegant appearance, very strong decorative wood flooring. Parquet floor unit consists of several separate solid wood blocks and an angled equilateral stitching quadrilateral or hexagonal or octagonal principle, forming a unit of solid wood parquet on the wooden plate of the lower plate connected to the load, or every two phases Adjacent wood sticks or solid blocks, between two adjacent metal pieces of furniture between the links; or every two adjacent blocks of wood and tenon and tenon, respectively, reed, wood line on each side Ventilation slots with the same direction as moisture. A facade, a square, a square, a rhombic, a parallelogram, a trapezoid, a regular polygon, an arbitrary polygon, a circle, a fan, and a plurality of corners. Shaped masonry floorboard assembly spliced ??into the battle, fighting the flowers, and then stitching the floor to assemble the parquet flooring, or by a number of flower-shaped, curved, including a variety of curved shapes; Flower floor, constitute a rule or irregular pattern.

- Q: Do you want to play keel with solid wood flooring?

- There are four kinds of solid wood flooring installation methods: 1) keel pavement method: that is, wood keel and steel keel pavement method, this is the need to do wood keel. 2) Suspended pavement method: that is, the use of moisture-proof film or moisture-proof pad to install, this method is more popular way. 3) direct paste method is environmentally friendly floor glue paving method. 4) Wool floor bottom method. This is the main installation method of solid wood flooring, the installation method is different, need different tools and materials. 1) Before the floor is installed, the parquet is in place. The installer needs to check the number of floors and the number of accessories with the customer first, and check whether there is any damage, and ask the customer to confirm the signature. Then, to confirm the amount of floor, the ground flatness, the use of auxiliary materials, wait until everything is correct, and then install. 2) After installation must pay attention to acceptance, the main is the surface of solid wood composite floor should be clean, no burr, groove marks, corners without defects, paint fixed burning incense dredging Fugui feather Japonica full, no leakage paint, laying firm. Solid wood composite flooring can not play keel can be, however, solid wood composite keel will make the foot will be better, step up very soft.

- Q: Which brand of composite flooring is durable?

- Composite flooring is generally very durable, good composite floor brands are: the elephant, Cicero, Filingel, Del, Shengda, Kyrgyzstan, Yangtze, Sao Paulo and other well-known floor brand

- Q: What is the difference between the three-storey and multi-storey parquet? The more layers the better? More

- Three-layer solid wood flooring is the use of three different kinds of wood intoxicated Fengtong sedan tampering ax rough material from the surface layer of practical hard wood middle and bottom practical soft wood has added a solid wood elasticity has a relatively lower cost Multi-layer solid wood composite flooring with multi-layer plywood as the substrate surface mosaic hardwood sheet by aldehyde resin laminated

Send your message to us

High Quality WPC Co-extrusion Composite Decking Past CE

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords