High Quality Rock Wool Heat Insulation Ceramic Fiber Board - Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

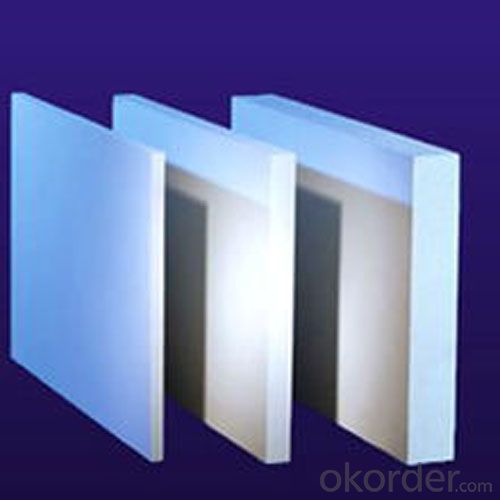

Ceramic Board Description:

1. Ceramic board is a lightweight refractory material processed with alumina-silica fibres for applications at temperatures up to 1600C.

2. Ceramic board is a vacuum formed product that resists higher gas velocities than ceramic fiber blanket.

3. Ceramic Board is ideal for furnace,boiler duct and stacking lining dut to its low thermal conductivity and low heat storage allowing shorter cycle times and quicker access for maintenance.

Ceramic Board Applications:

1. Ceramic Board : Refractory lining for industrial furnace.

2. Ceramic Board Combustion chamber liner, boilers and heater.

3. Ceramic Board Back-up insulation for monolithic refractories.

4. Ceramic Board Transfer of non-ferrous metals .

5. Ceramic Board Expansion joiot boards.

6. Ceramic Board Barrier against flame .

Ceramic Board Advantages:

1. Low heat storage.

2. Low thermal conductivity.

Ceramic Board Specification:

1. 600*400*20-50;900*600*20-50,other made according to customers's requirement.

| Grade | COM | STD | HP | HA | HZ | |

| Specifieation temp(°C) | 1260 | 1260 | 1260 | 1400 | 1400 | |

| TENGLONG STYLE | 4220COM | 4220STD | 4220HP | 4220HA | 4220HZ | |

| Working temp(°C) | <1000 | 1000 | 1100 | 1200 | 1350 | |

| Colour | White | White | White | White | White | |

| Density (kg/m3) | 260 | 260 | 260 | 260 | 260 | |

| 320 | 320 | 320 | 320 | 320 | ||

| Rate of liner(%) | -4 | -3 | -3 | -3 | -3 | |

| (1000°C) | (1000°C) | (1000°C) | (1200°C) | (1350°C) | ||

| Rate of thermal Conductivity(W/m.k) (128kg/m3) | 0.085 | 0.085 | 0.085 | 0.085 | 0.085 | |

| (400°C) | (400°C) | (400°C) | (400°C) | (400°C) | ||

| 0.132 | 0.132 | 0.132 | 0.132 | 0.132 | ||

| -800 | -800 | -800 | -800 | -800 | ||

| (1000°C) | (1000°C) | (1000°C) | (1000°C) | (1000°C) | ||

| Tensile Strength (MPa)(128kg/m3) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | |

| Chemical Composition(%) | A1203 | 44 | 46 | 47-49 | 52-55 | 39-40 |

| A1203+SiO2 | 96 | 97 | 99 | 99 | - | |

| A1203+SiO2+Zr02 | - | - | - | - | 99 | |

| Zr02 | - | - | - | - | 15-17 | |

| Fe203 | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 | |

| Na20-K20 | <=0.5 | <=0.5 | 0.2 | 0.2 | 0.2

| |

Packaging & Shipping

1. Our packaging is as per customer's request.

2. Normal goods delivered by sea transport.

3. Sample shipping by express.

Our Services

1. Your inquiry related to our products or prices will be replied within 24hours

2. Well-trained and experienced staffs to answer all your enquiries in fluent English.

3. All our products have 1-year warranties.

4. Offering the support to solve the problem in the application or selling period.

5. Competitive prices based on same quality.

6. Guarantee samples quality same as mass production quality.

- Q: What does the rock wool board look like?

- What does the rock wool board look like?

- Q: What role does dolomite play in rock wool products?

- Pu hard foam layer can be firmly bonded with the base layer, the adhesive strength can exceed the tear strength of the foam itself, so Pu hard foam and the formation of the base layer, easy to delamination, to avoid the water along the interlayer

- Q: Rock wool products are divided into several categories

- In the rock wool by adding special adhesive can be processed into rock wool board, rock wool stave, rock wool insulation and other products, as the building insulation, insulation, cold, sound-absorbing material

- Q: How to judge the quality of rock wool

- Heat load shrinkage temperature: heat load shrinkage temperature used to characterize the rock wool board moisture and heat stability, is to wet the rock wool product samples soaked in the gradual heating of water, rock wool products at a temperature of 643 degrees will begin to shrink , So rock wool products load shrinkage temperature of 643 degrees, that is to say in the outside temperature of 643 degrees when the rock wool board will be deformed.

- Q: The difference between rock wool and rock wool

- Yanmian tube is a kind of rock wool insulation material mainly used in the pipeline. After the natural basalt is melted by high temperature, the artificial inorganic fiber is made from the high speed centrifugal equipment, and the special binder and dustproof oil are added. Temperature curing, made into a variety of specifications, different requirements of the rock wool insulation tube

- Q: Rock wool products and aluminum silicate acupuncture blankets are same

- Rock wool products and aluminum silicate acupuncture blankets are same

- Q: Rock wool insulation material fire rating is how much

- Fire protection and noise reduction of the elevator shaft of the building wall, the roof of the insulation, the firewall, the fire door, the large and medium diameter pipes, the small and medium sized storage tanks, the kilns, the thermal power plants, Boilers and other equipment insulation.

- Q: Rock wool board is inorganic composite insulation material

- Insulation material A-level fire is organic meet the inorganic meet resolutely

Send your message to us

High Quality Rock Wool Heat Insulation Ceramic Fiber Board - Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords