High Quality Gost Standard LED Recessed Ceiling Light Fixtures

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- -

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Introduction

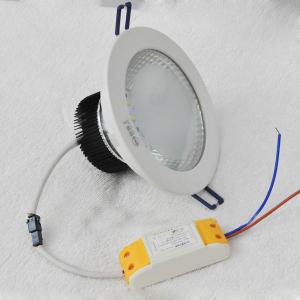

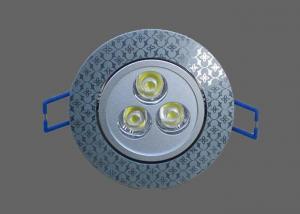

GOST standard led recessed ceiling light fixtures

Specification

| Iterm name | 3W led down light |

| Color | white/Warm White |

| work voltage/V | 90-265V |

| Power consumption | 3W |

| Dimension/mm | Φ75*25mm |

| Hole cutting size | Φ72mm |

| LED Quantities | 15pcs |

| Color temperature | 2700K~6000k |

| Luminous Flux | 156LM |

| life-span | 35,000hrs |

| Beam Angle | 120° |

| Waterproof | Indoor usage |

| Package | 100pcs/carton |

IP rating | IP33 |

Mask | flick-proof |

Power adapter | good quality power adapter |

Product features

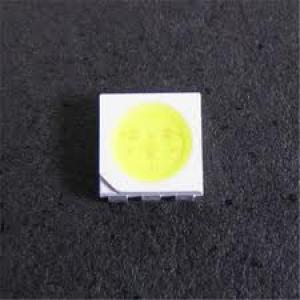

1. Using high lumen COB light source high intensity aluminum shell ,heat faster.

2.Using good reflectivity light leading board ,it is thinner and brighter ,the lights is more equally.

3.Low voltage and constant current driver ,no glare,the light is soft.

4.Launch in 0.01sec,no flashing,no noise ,no radiation. Energy saving,belongs to grand environmental light.

5.This product can show high brightness, without seeing the lamp itself.

Suitable for: household ,exhibition hall,hotel,shops ,jewelry store,museums,stores and receational space,etc.

Product details:

1. The input line of the lamp plus fixed clamp,is not easy to fall off.

2. Specific stainless steel spring ,no rust ,not easy to deformation.high elasticity,high safety.

3. Flat stainless steel screw,parallel with the back of the lamp.

Other

Payment Terms:A/D,D/P, T/T , L/T, Western Union,paypal

Delivery Time:20-45 days after confirming payment

Warranty: 2 years

Shipping method:As your requests,By Express(DHL,UPS,TNT,Fedex),By Air,By sea are optional

Note

the applied ambient temperature must be lower than 40.

not suitable for poorly ventilated lighting fixtures.

not suitable for outdoor .

Caution:

1. Confirm the goods have no damaged during the transportation before using .

2. Packing materials should be stayed away from children,prevent children from playing the plastic bag and small accessores lead to suffocate or swallowed.

3. Put away from the children,do not let the children touch the lamp when it is working.

4. Don't cover any things on the products .Put away from the fire or high temperature object .

5. Laypeople can not tear doen or maintain the product .We have the authority to refuse giving any warranty to the products which are repaired without our instruction.

6. Please shut off the power before clean the lamps.Only use the dry dish cloth to clean .Don't use any chemical or corrosive material to clean the lamps.

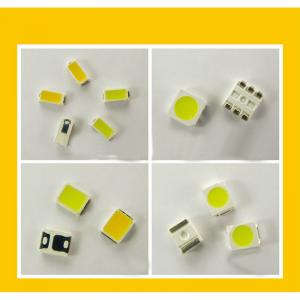

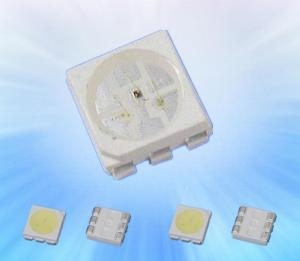

- Q: What determines the brightness of the patch LED?

- Lamp brightness level itself, is also in the rated current situation, its brightness

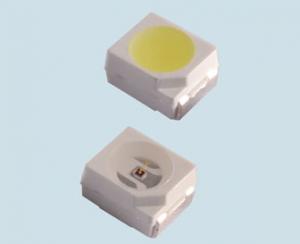

- Q: What is the difference between SMT LED packaging with silicone and epoxy resin transparent package? What is the market situation of these two types of packaging?

- At present, it is basically made of silica gel, and the epoxy resin is very few. Only those with lower price may use some. Why is it rare to use epoxy? Because of the use of LED epoxy patch cited some discomfort because the cable used in the above: reflow welding, high temperature resistant epoxy epoxy and silicone not lead to separation, produce decay dead lights etc..

- Q: How can I install the patch LED lamp belt on the wood chip casting board? With double-sided glue will be hot, and can not use the clip on the screw, what should I do?

- Installed indoors, you can directly tear off the stickers on the 3M double-sided adhesive surface, and then fix the light bar where it needs to be installed. Just press it with your hands.

- Q: Led lamp and Led patch two what is the difference between ah, the feeling is a patch of long service life, whether or not? 5-10 meters pan area lighting lamp selection Everbright shaped or patch shape?

- First of all, I want to say, in the same light emitting chip case, two is not what were, just a different process is a DIP plugin, a SMD patch process, the 3 floor of the right, just some high grade patch.

- Q: What, in what way do I shunt the LED?

- LED lights are current driven, first of all, look at your LED's IF and VF values. How much power do you have?. Make sure the current is in line with the IF and the current limit can be achieved with resistors.

- Q: Patch LED beads can be bought in what place?

- If you don't want to constantly change with it, suggest you go to OSRAM, Nichia, Corey, Taiwan Tongjia enterprise authorized agency purchase.

- Q: What does patch LED light mean?

- The screen is divided into standard lamp and patch type, the light emitting diode lamp is inserted into the circuit board, and the patch is a patch welded on the circuit board. Two light sources are not the same. If only light, not so clear.

- Q: Patch LED market conditions

- Chinese suppliers also offer mature, but less profitable two-color and trichromatic products, which are mostly used in backlighting, appliances, consumer products, consumer electronics and display. Despite low market demand, vendors continue to offer sideview SMD LED, including 335 (4008), 020 (3806) and 215 (2810)

- Q: What is the difference in performance between the LED plug-in and the LED patch?

- 1, the patch is relatively easy to heat dissipation, can be directly welded on the aluminum substrate, heat faster.2, in general, there is a straw type shell, general lighting has front facing directivity, just look at it, brightness will be the biggest. The patch has a relatively wide divergence angle and is more suitable for fluorescent lamps.

- Q: How do led patches measure good or bad?

- LED patch how to measure methods: use two meter meter test, red pen is positive, black pen negative, if there is "bee" sound is bad, if the light is good

Send your message to us

High Quality Gost Standard LED Recessed Ceiling Light Fixtures

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- -

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords