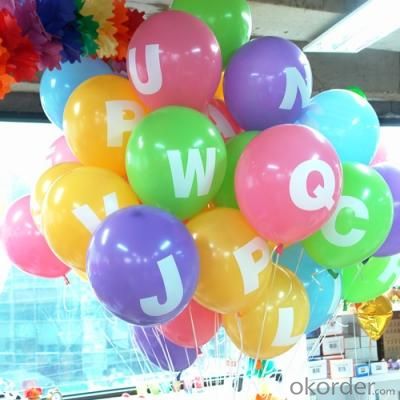

High quality custom printed led ballon

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Custom printed artwork balloons,Free shipping to worldwide

Material | 100% Natural Latex SGS,En71 |

Use | Advertising,promotion,party,event,wedding |

Festival | all holiday |

| skype: | wlballoon |

Certificate | EN71 part1,2,3 ASTM F963,CPSIA(H.R.4040) ,Nitrosamine-free |

Colors | Red, orange, yellow, pink, white, dark green,light green,blue,light blue, black,purple,rose |

Logo/artwork | your design or we help design |

Shape | Round or heart shape |

packing | 100pcs/polybag,50bags/ctn |

delivery time | 2-10 days delivery time according to order quantity Custom printed balloons,Free shipping to worldwide Material100% Natural Latex SGS,En71UseAdvertising,promotion,party,eventFestivalall holidayskype:wlballoonCertificateEN71 part1,2,3 ASTM F963,CPSIA(H.R.4040) ,Nitrosamine-freeColorsRed, orange, yellow, pink, white, dark green,light green,blue,light blue, black,purple,roseLogo/artworkyour design or we help designShapeRound or heart shapepacking100pcs/polybag,50bags/ctndelivery time2-10 days delivery time according to order quantity |

light up balloons

- Q: What are the differences in the properties of neoprene models?

- Good physical and mechanical properties, oil resistance, heat resistance, fire resistance, sunlight resistance, ozone resistance, acid and alkali resistance, chemical reagents. The disadvantage is cold resistance and poor storage stability. With high tensile strength, elongation and reversible crystallinity, good adhesion. Aging resistance, heat resistance. Excellent oil resistance and chemical resistance. Weatherability and ozone resistance are second only to that of ethylene propylene rubber and butyl rubber. The heat resistance and the nitrile rubber, the decomposition temperature of 230~260 DEG C, short-term resistance at 80~100 DEG 120~150 DEG C, can be used for a long time, with a certain flame retardancy. Oil resistance second only to nbr. Good resistance to inorganic acids and alkalis. Cold resistance is slightly worse, electrical insulation is poor. Rubber poor storage stability, will have a "sulfur" phenomenon, Mooney viscosity increased, hard rubber. Foreign brands are: AD 1, 30 (USA), A-90 (Japan), 320 (Germany), and MA40S (France).

- Q: What are the uses of rubber oil?

- Also can be used for chloroprene monomers such as polymerization inhibitor, antiseptic coating waterproof material, such as veterinary medicine.

- Q: How much is the recipe for Buddha's rubber?

- Bo siangong Zhejiang university disciplinary advantage and analysis of detection rely on talent, with a variety of methods of analysis and testing, has accumulated rich experience in chemical products analysis, qualitative analysis and quantitative identification of unknown compounds through professional, reliable, comprehensive separation and detection means for adjusting the formula, in the research and production of new product development, to provide scientific production process improvement on the basis of, can also according to customer needs, provide follow-up technical guidance.

- Q: What's the difference between silicone rubber and 703.704 glue?

- 704, temperature range of -50-250, better temperature effect, mainly used for sealing electric heating devices; electric plug sealing; instrument, instrument bonding and sealing.

- Q: Rubber rolling process for making rubber products

- The rolling process has become a rolling process.The principle of rolling process: using pressure between the calender roller, the material plastic flow deformation, the final film made with the size and geometry of the provisions of section a section, or the rubber covering process in textile or fabric made of metal surface has a certain thickness of the tape section.

- Q: How to maintain and store the rubber material?

- Rubber itself is a shelf-life, you can ask the supplier to warranty, above all, as fillers, such as calcium carbonate, carbon black, long time no problem, also have a shelf life of antioxidant promoter, especially individual species. When storing, pay attention to fire prevention, moisture-proof, away from the high temperature, avoid direct sunlight, of course, the general "first in first out" is a must follow the truth.

- Q: What are the forming methods of rubber products?

- In rubber products, the main molding technologies are molding, forming, transfer, forming, wrapping, molding and injection molding.

- Q: What are the ingredients in the tires?

- Tires are usually composed of 3 parts of tyre, tyre, cushion belt. The inner layer of the fetus body has the rubber layer with good air tightness, and a special wheel rim is required. The structure of tire in the world has been developed in the direction of tubeless, radial structure, flat (smaller ratio of height to width of tire section) and light weight.

- Q: What is rubber leather?

- The general rubber has good comprehensive properties and is widely used. The main contents are as follows: natural rubber. From the latex of the Hevea tree, the basic chemical composition is cis polyisoprene. Good elasticity, high strength and good comprehensive performance. Isoprene rubber. The full name is cis -1, 4- polyisoprene rubber, a high CIS synthetic rubber made from isoprene, because of its structure and properties similar to natural rubber, it is also called synthetic natural rubber. Styrene butadiene rubber. Referred to as SBR, made by copolymerization of butadiene and styrene. According to the production method, emulsion polymerization, styrene butadiene rubber and solution polymerized styrene butadiene rubber are divided into emulsion polymerization. Its comprehensive properties and chemical stability are good. The br. The full name is cis -1, 4- polybutadiene rubber, referred to as BR, made from butadiene polymerization. And the other than universal rubber, vulcanized butadiene rubber cold resistance, abrasion resistance and excellent elasticity, dynamic load, less heat, good aging resistance, easy and natural rubber, chloroprene rubber, nitrile rubber and etc..

- Q: Is carbon black and conductive carbon black used in rubber?

- Conductive carbon black is a kind of carbon black used in rubber. After adding rubber, it can make the rubber which has not poured electricity have conductivity characteristics, but the resistivity is higher, and it can't be used as conductor for current load

Send your message to us

High quality custom printed led ballon

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords