Raw Materials for Refractory:High Purity 99% Silicon Carbide SiC Tubes with ISO Certificated

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

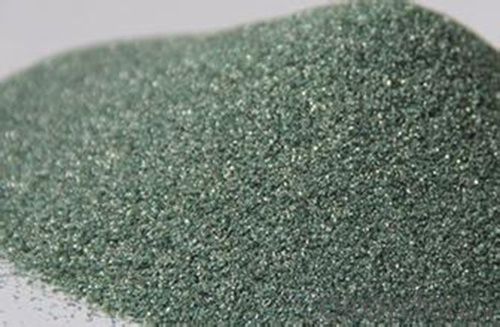

Description of Silicon Carbide Sic Tubes

Silicon carbide (SiC), also known as carborundum, is a compound of silicon and carbon with a chemical formula SiC. It occurs in nature as the extremely rare mineral moissanite. Silicon carbide powder has been mass-produced since 1893 for use as an abrasive. Grains of silicon carbide can be bonded together by sintering to form very hard ceramics which are widely used in applications requiring high endurance, such as car brakes and ceramic plates in bulletproof vests.

Electronic applications of silicon carbide as light emitting diode and detector in early radios have been demonstrated around 1907, and nowadays SiC is widely used in high-temperature semiconductor electronics. Large single crystals of silicon carbide can be grown by the Lely method; they can be cut into gems known as "synthetic moissanite". Silicon carbide with high surface area can be produced from SiO2 contained in plant material.

- Q: what grades are fire resistance of fireproofing glass divided into?

- Fireproofing glass is a kind of special glass which can keep its integrity and thermal insulation performance in regular insulating refractory trials. and it can be divided into three classes according to its fire resistance: Class A, it's a kind of fireproofing glass that can satisfy the requirements of refractory integrity, refractory and thermal insulation at the same time. This kind of glass has the properiyies of transmittance, fireproofing ( smoke insulation, fireproofing, and keeping out thermal radiation), sound insulation, shock resistance, and it's suitable for steel and wooden fire door of building decoration, windows, varnishing, partition walldaylighting?roof,ceiling?screen,perspective floor and other construction components demading for transparency and fireproofing. Class B, it's a kind of fireproofing glass that can satisfy the requirements of refractory integrity, refractory and thermal insulation at the same time. Such kind of fireproofing glasses mostly are composite fireproofing glasses and has characteristics of transmittance,fireproofing and smoke insulation. Class C, it's a kind of fireproofing glass that only satisfies the requirements of refractory integrity. This kind of glass has characteristics of transmittance, fireproofing, smoke insulation and high strength,etc. It's suitable for fireproofing glass partition wall, fire Windows, outside curtain wall and other places without insulation requirements.

- Q: Does anyone know the difference between refractory and thermal insulation material?

- I will give you a relatively simple analysis. Refractory can bear above 1,200 degrees centigrade, but some refractory is not insulated. For example, refractory brick can be directly in contact with heat source, but it has little insulation effect. Refractory includes ceramic fiber, high silica and so on. And they can be also insulated. But insulation effect is not so good as insulation material. Insulation material generally can bear below 800 degrees centigrade, and it is large in thermal resistance, low in heat conductivity coefficient and high in porosity factor, thus reducing heat loss. Briefly speaking, insulated material is to store most heat, and just let a small quantity of heat run of through air, thus insulating heat. Refractory includes glass fiber, rock wool, aerogel blanket and so on.

- Q: what's the varieties of fire-proof?sealing?material?

- ATD-AB, organic fire-proof caulking, fire retardant bag, fire retardant net, fire retardant ring, fire barrier wrap, fireproofing sealing strip, flexibility fireproofing coiled material, fireproof glue, etc., fireproofing sealing materials currently on the market can be divided into two types, one is the traditional type: flexible organic caulking, WXY-II, fire retardant bag, fire?bulkhead, cable refractory coating; there are some new materials used in large-scale projects: fireproofing coating board system (fireproofing coating board, intumescent fireproof sealing tape, elastic fireproof sealant, Waterborne Fire-retardant Coating), fire retardant module system (fire retardant module, sealing gum, cable refractory coating), fireproofing plaster system (fireproofing plaster, sealing gum, cable refractory coating).

- Q: Who knows the fire rating of fire?partition with steel stud?

- Cement board wall of steel stud: it is used for walls with ceramic in kitchens, restroom, disinfect room, etc. If single-sided tile is made, cement pressure plate can be used on one side. Gypsum board is used on the other side. Fire?rating is A1. CaSo4.2H2O is molecular structural formula of gypsum which contains 20% water, crystal water and free water. When 10% water slowly evaporates on the flame surface, there is still 10% crystal water. Itself is grade A fire retardant material. 1 hour. It is in line with the fireproof test standard of national building materials. It can reach up to 4 hours at most.

- Q: Who knows how to divide the building fire grade and fire resistance grade?

- I hope to help you building fireproof rank division is one of the most basic measure in building fire safety technical measures, Building's fireproof rank is divided into class one, two, three, four according to China's architectural design specification. Fire-resistant capability of the highest level is the strongest; Fire resistance of four level of the weakest. The fire resistance level of a building depends on the combustion performance and fire resistance of the building components that comprise the building. The so-called building component refers to a series of basic components, such as wall, foundation, beam, column, floor, stair, ceiling and so on.

- Q: What refractories are used in various parts of the blast furnace.

- Blast furnace from top to bottom has the throat, hearth staves, waist, bosh, hearth and furnace bottom. the specific structure is as follows: The throat is the first to be affected by the impact and abrasion, generally use high-density alumina bricks. the upper and central portion of temperature furnace is only 400 ~ 800 ℃, the area with high alumina bricks and silicate bricks. The lower part of furnace is subject to erosion and dust erosion alkali metal vapor due to high temperatures, it is required in such case to use high quality clay brick,high alumina brick,carborundum brick,corundum brick that is slag resistance and alkali?resistance, temperature resustant and wearproof. Furnace bosh temperature reached 1400 ~ 1600 ℃, serverly eroded by slag,vapor, flush. so we use carborundum brick and reaction-bonded silicon?carbide?brick. Bosh temperature reaching1600 ~ 1650 ℃, using alumina brick, corundum brick or silicon carbide brick. the temperature of Hearth near the upper portion of the outlet zone at 1700 ~ 2000 ℃, use of silicate bricks and corundum castable graphite filler, silicon carbide bricks. In 1450 Silly twitch bottom temperature sealing die of hunger slander bet phoenix astringent preserved Grade ~ 1500 ℃, use of graphite bricks and microporous carbon bricks, now use more corundum brick, corundum mullite brick and synthetic mullite brick. x26lt;P class x3d "share-btn"x26gt;

- Q: What is the difference between the fire?rating and the fire resistant level of the fire-fighting equipment?

- Hello there. Fire rating and fire-fighting rating are the misnomer to the building fire resistant level. The building fire risk is measured by fire resistant level. The article 3.2.1 and 5.1.7 of "Architectural design code for fire protection" have made provision respectively on the fire resistant level of plant (the storeroom) and civil construction. Article 3.0.2 of "Code for fire protection design of tall buildings" has made provisions on the fire resistant level of tall buildings. As for the warehouse building "category malonate", it refers to one of the fire risk of goods storage, which is divided into A, B, C, D, E, and each category is refined depending on the nature of different substances. "Malonate class" specified in article 3.1.3 of "building design for fire protection" refers to the flammable solid.

- Q: what is the Specifications Grading for Fireproof rubber insulation materials ?

- At present, China Building Materials has two grading criteria for combustion performance. "Combustion Performance Classification Method of Building Materials" and "Combustion Performance Classification Method of Building Materials and Products" (GB8624-2006). Among them, one of the major changes of GB8624-2006 and GB8624-1997 is to divide the material combustion performance grading from homogenous material)Class A (composite sandwich material), B1, B2 and B3 level five minutes as A1, A2, B, C, D, E, F seven levels.

- Q: What are the materials of class A fire resistant window?

- Environmentally friendily, non-poisoned non-peculiar smell, non-radioactive; non-combustible, fireproof, moisture-proof, corrosion-resistant; easy to operate, lightweight, high strength, themal insulation, sound insulation; able to be cut, planed, sawed and carved. It also meets GB8624 -2006A1 level non-combustible standards. Lightweight, high strength, anti-aging, corrosion resistance; meeting the GB / T20285-2006 Opium (AQ1) safety and environmentally friendly products; Foamed fire door core board specifications: 2100 × 900 × (26 ~ 65) mm; 2050 × 850 × (26-65), and many other specifications. I hope my answer can help you.

- Q: What's the fire endurance of A grade fireproof glass curtain wall?

- The following is fire endurance of A class fireproof glass curtain wall. Fire endurance of the fire window: A class fire window: no less than 1.2h; B class fire window: no less than 0.9h; C class fire window: no less than 0.6h. Technical requirements: 1. Materials and fittings: (1) Window frame should adopt the steel frame or wood frame with certain strength so as to guarantee the integrality and stability of the fitting; (2) Steel frame and mound layer can choose the galvanized steel sheet or stainless steel sheet. Its selection standard is in line with provisions of Article 5.1 in GB12955 "General Technical Requirements on Steel Fire Doors"; (3) Selection standard of wood frame and mound layer should be consistent with the provisions of Article 5.1.1 in GB14101 "General Technical Requirements on Wood Fire Doors"; (4) Filler material inside the steel frame and wood frame should be incombustible material; (5) Fireproof glass can choose the qualified product with no influence on the fire resistance test of the fire window, and its light transmittance should be no less than 75% of that of the ordinary sheet glass with the same layers; (6) Sealing material between the frame and the fireproof glass should use flame retardant material which can play the role of fire prevention and smoke insulation in case of fire. Hope it's helpful for you.

Send your message to us

Raw Materials for Refractory:High Purity 99% Silicon Carbide SiC Tubes with ISO Certificated

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords