High Productivity Automatic Fiberglass Vessel Winding Machine with Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 25 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

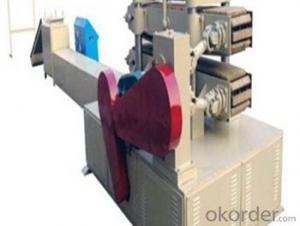

High Productivity Automatic Fiberglass Vessel Winding Machine with Good Price

Product Description:

Themachine is popular for site work, It is controlled by PLC. After input/preset the parameter, the computor can calculate and design the product data automatically, then control the rotating speed of moulds and moving of dolly to achieve loop winding, across winding and spiral winding.

Product Feature:

1.Versatile,flexible dependable,Cost-effective

2.High strength,low weight, high corrosion resistance

3.Simultaneous CNC control,low maintance,long using life

4.Less space,high automatic,low labor required.

5.Prefessional and experience engineer production service

Product Parameter:

Name | High Productivity Automatic Fiberglass Vessel Winding Machine with Good Price |

Brand | CMAX |

Weight | 5T |

Dimension(L*W*H) | 12mX3mX2m |

Power | 5.5kw |

Voltage | 420V |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Application | Granules |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Guangdong, China (Mainland) |

Color | Customized |

Warranty | 13 Months |

Time of Delivery | 30-45 days |

Product Pictures:

Our Services:

1.OEM service offered.

2.Engineers available for overseas customer, for machine trial and teaching.

3.Suggest related material and mold for you, turn-key business to save your time.

FAQ:

1)Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world.

2)Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly

3) Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications.

4) Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. The core of our company culture is honesty and credit. If you check with okorder, you will see that we have never got any complaint from our customers.

- Q: What machine does the pattern design of this mass produced plastic product use?

- Hello, let me answer the question for you: you can open your mobile phone, Baidu, and then enter your current location, and then enter the address you want to query. The Baidu maps will automatically navigate the nearest route for you.

- Q: What are the plastic finishing machines?

- Mechanical features are: machinery is a combination of artificial physical components. A definite relative motion between the parts of a machine. So the machine can convert mechanical energy or perform useful mechanical power, is the modern mechanical principle in the basic concept, the modern concept of multi-source Chinese mechanical word from the Japanese "machinery", Japan's machinery products do the following definition of mechanical concept (that is consistent with the following three features called Machine).

- Q: How much does it cost to process disposable plastic bags?

- Ruian pine machinery factory production of such machinery is probably 19 to 220 thousand of the way, Taiwan produced more expensive, most of the price is more than 300 thousand bar,

- Q: What is the function of adding filler in the processing of plastic products?

- 1., increase the strength: with glass fiber, can greatly increase the mechanical properties of plastics, tensile strength, bending strength, impact strength2., reduce costs: without reducing the strength of plastic, the addition of some fillers, such as talc, calcium carbonate, etc., can reduce the cost of plastics, but also increase the strength of the role.3., flame retardant effect: add flame retardant can be made into refractory plastic products.4. anti-aging: the addition of antioxidants can increase the anti-aging properties of plastics.5. lignite wax: to improve the flow of plastic, improve injection molding effect.

- Q: from raw material to particle forming, need several devices, what are they? _?

- I also want to open such a factory, does the profit? I'm using scrap plastic as a particle here, so I want to check it out.

- Q: Which kind of engineering plastics has good processability?

- Organic glass rods and plates, PTFE rod material, nylon rod, PVC sheet and other mechanical processing performance is good.

- Q: What's the price? How much does it cost to run a processing plant? What's better about that one?

- There are two kinds of plastic bottles: injection, blow and blow.Injection blowing is the two step, that is, injecting the bottle embryo first and then blowing it into a bottle. The machine mainly has the injection molding machine and the bottle blowing machine and the auxiliary machine and the corresponding mold.

- Q: How can we deal with the pollution of waste plastic particles?

- You don't know how much the plastic granulator industry, it is understood that in recent years the development of plastics recycling industry is very rapid, all kinds of plastic granulation machinery are constantly upgrading equipment in energy saving and environmental protection have been greatly improved, for now the sample or engaged in environmental protection and is engaged in waste plastics friend concerns, we explore look.

- Q: How are the plastic products made of this texture processed?

- Plastics processing technologyPlastic forming process. It is a general term for various processes that convert synthetic resins or plastics into plastic products. It is a larger manufacturing sector in the plastics industry. Plastic processing generally includes plastic batching, molding, machining, bonding, modification and assembly. The latter four processes are carried out after the plastic has been molded into products or semi-finished products. It is also called plastic two times processing.Mixed ingredientsPlastic processing of raw materials, in addition to the polymer, usually also added a variety of plastic additives (such as stabilizer, plasticizer, lubricant, coloring agent, reinforcing agent and filler etc.), to improve the performance of molding process and product or reduce the cost of products. The additive and the polymer are mixed and evenly dispersed into powder, also called dry mixed material. Sometimes, the powder is also processed into pellets. The powders and pellets are referred to as synthetic or moulded plastics.

- Q: In Shengze where you can find what rags processed into a plastic factory

- You mean it woven rags! Use a plastic granulator.

Send your message to us

High Productivity Automatic Fiberglass Vessel Winding Machine with Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 25 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords