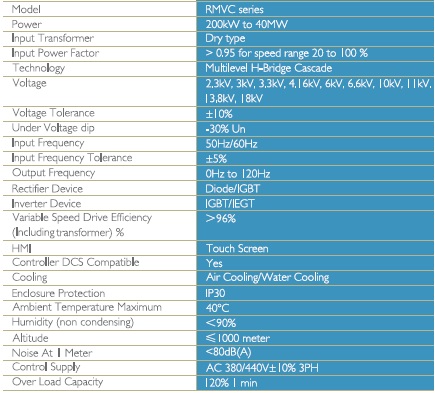

High Medium Voltage Drive 4.16KV 800KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Energy-saving Solutions for Enterprise

1、Program Overview

◆Saving energy achieves 10% -70%

◆The enterprises do not need to pay for expense of equipment manufacture and installation.

◆Enterprises only need to pay the saving electricity expense to our company according to the actual quantity of energy saving after the equipments put into operation.

◆According thousands of the projects’ implementation experiences, such projects recover the investments in three or four years. (Equipment service life is 15 years)。

◆Our company will no longer charge the saving electricity expense after recovering the investment.

The significance of the program:

1)、Concentrate on solving problems of energy conservation, make enterprises’ energy-saving work reach new level and take their social responsibility。

2)、Avoid the enterprises reactive power fine of low power factor caused by electric energy using (according to Ministry of Electric Power and Water Resources, State Price Control Bureau establish the " measures of power factor adjustment expense ").

3)、Avoid the high-energy consumption enterprises are implemented differential prices because of the changes of national power regulation.

4)、For the standard-conforming large-scale (saved energy equal 10 thousand tons standard coal or more) energy-saving technological transformation projects, China will reward the enterprises for energy saving which based on the "Financial Incentives Interim Measure for Energy-saving Technological Transformations" established by Ministry of Finance, the National Development and Reform Commission.( Amount of 200 yuan / ton of standard coal).

5)、Equipments recovery period is generally 3-4 years, each period payment equal to the amount of current energy-saving benefits, and equipments service life are 15 years, so enterprises will gain huge energy-saving benefits.

2、Implementation Process

Energy Audit

Energy Saving Program Design

Construction Design

Equipments Manufacture

Construction and installation

Maintenance and Repair

Energy Monitoring and Efficiency Insurance

Recovery of Program Investment

3、Program Features

High energy-saving efficiency

The project saving rate is generally 10% -30%, highest is up to 70%.

Clients Zero Investment

All works of design, audit, manufacturing, construction, monitoring are handled by RXPE, clients does not require investment.

Energy-saving Guarantee

RXPE promises the amount of energy saving, ensuring that clients’ cost reduction immediately.

Short Investment Recovery Period

The investment recovery period is short, average period is 3-4 years.

Low Risk

Customers do not input large sums of money also can enjoy professional energy-saving products, technologies and services, and the investment risk is very low.

Improvement of Cash Flow

Customers with the support of RXPE approve energy-saving program to improve cash flow, invest the limited funds into other priority investment areas.

Enhance competitiveness through implementing energy conservation, improving energy-saving efficiency, reducing energy costs and enhancing the quality of environment, establish green corporate image and enhance market competiveness.

- Q: The parameters of the inverter is 4, 6 motor can be used

- The inverter is mainly composed of rectifier (AC variable DC), filter, inverter (DC variable AC), brake unit, drive unit, detection unit micro-processing unit and so on. The inverter will adjust the voltage and frequency of the output power by the breaking of the internal IGBT, according to the actual needs of the motor to provide the required power supply voltage, and then achieve the purpose of energy saving, speed control, in addition, the inverter has a lot of protection , Such as overcurrent, overvoltage, overload protection and so on. With the continuous improvement of industrial automation, the inverter has also been a very wide range of applications.

- Q: How to choose the right inverter?

- 1, constant power load During the operation of the load device, the power remains constant. Such as machine tools, cutting machines, paper machines and so on. For example: a marble cutting machine frequency conversion system, is a constant power load, load inertia, inverter selection configuration A power with the G-type machine, plus the braking unit and braking resistor.

- Q: A 4-pole AC motor into a 2-pole AC motor, the motor is controlled by the inverter, to make the maximum speed of the 2-pole motor and the original 4-pole

- First reduce the frequency of about one-third of the test, not the case, then appropriate adjustments!

- Q: Inverter alarm a043, how is it

- When a signal failure occurs, use the DTI board, if necessary, change P215. With P806 (Follow the parameter description) during operation can be converted to no encoder operation A043 is: n-actjump exceeds the allowable change speed of the speed encoder signal (P215) In addition, for the synchronous motor (P095 = 12): The motor speed is 2% higher than the inverter release time point. The inverter in the ready state can not exit. Check processing: Check if the cable is disconnected Check the tachometer to shield the ground Not only on the motor side but also on the inverter side The encoder cable does not allow disconnection Use only recommended encoders The encoder cable is not allowed to be laid with the power cable

- Q: What is the application of variable frequency speed control?

- Frequency conversion is to change the power supply frequency, thus regulating the load, play a lower power consumption, reduce losses, extend the service life of the role. Frequency translation. Frequency conversion technology is the core of the inverter, through the conversion of the power supply frequency to achieve the motor speed regulation of the automatic adjustment of the 50Hz fixed-line frequency to 30-130 Hz change frequency. At the same time, also make the power supply voltage to adapt to the range of 142-270V, to solve the power grid voltage instability caused by electrical work problems. By changing the AC frequency of the way to achieve the AC control technology is called frequency conversion technology.

- Q: I have a 5.5 kilowatts of 4-pole motor, want to pass through the inverter, slow down to 130 per minute use, eliminating the need for speed,

- Power will drop, down to the original one-tenth

- Q: With the inverter control fan 37Kw4 pole with what model inverter

- Control the fan: select the fan pump with 37KW or 45KW inverter.

- Q: Can the four motors be tuned to 2900 rpm?

- Can be used, there are problems you can consult Zhoukou City bearing mechanical and electrical companies, contact the online search Zhoukou City bearing mechanical and electrical companies can search to!

- Q: 55 瓩 4 pole motor with a frequency of one hour can save much electricity

- it is used in the fan pump load can save about 14-22 kWh, used in the general category, on Multiply your number by 55.

- Q: Three motors, if coupled with the governor speed, is it necessary to add the inverter?

- ?Fifth, the hydraulic coupler speed: hydraulic coupler is a hydraulic transmission device, generally composed of the pump wheel and turbine, when the pump wheel in the prime mover driven under the rotation, in which the liquid is driven by the blade and rotation, in the Under the action of centrifugal force along the outer ring of the pump wheel into the turbine, in the same turn to the turbine blades to thrust, to drive the production machinery operation. Through different hydraulic (lubricants and turbines) to achieve speed.

Send your message to us

High Medium Voltage Drive 4.16KV 800KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords