high efficiency jaw crusher used for mining PE 150*250

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Jaw stone crusher machine:

1.ISO9001:2000

2.Price:negotiable

3.Capacity:5-800T/H

4.Payment terms:L/C or T/T

Jaw stone crusher machine:

1.ISO9001:2000

2.Price:negotiable

3.Capacity:5-800T/H

4.Payment terms:L/C or T/T

Jaw Crusher Description

The jaw crusher we offers are ideal for primary and secondary crushing. Jaw Crusher is one of the main types of primary crushers in a mine or ore crushing process plant and also is one of the most widely used crushing equipments in mining industry.We are famous jaw crusher manufacturers in China, and sold crusher machines to all over the world. This series of jaw crusher can reach the crushing ratio of 4-6 and the shape of final product is even. Because it is primary crusher, Jaw crusher is designed for long life service with minimum maintenance for hard, tough, abrasive material and overload high capacity

Jaw Crusher Working Principle

Primary jaw crusher is typically of the square opening design, and secondary jaw crusher is of the rectangular opening design. Jaw Crusher reduces large size rocks or ore by placing the rock into compression. A fixed jaw board, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the stationary plate. The space at the bottom of the "V" aligned jaw plates decide the crusher product size gap, or the size of the crushed product from the jaw crusher. The rock remains in the jaw until it is small enough to pass through the gap at the bottom of the jaws.

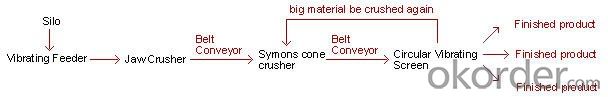

Brief introduction to stone crushing & screening plant

we manufactures various equipments for whole set of stone production line, and provide complete technical support for customers. The whole production line consists of Vibrating Feeder, Jaw Crusher, Impact Crusher, vibrating screen, Belt Conveyor, electric control cabinet and etc.

We design different production lines ranging 50 t/h to 500 t/h by combining different models of equipments.It is widely used for crushing hard limestone, granite, basalt, gravel, metallurgic slag, etc or artificial sand making for hydroelectric power, building material, high way, city construction, etc. Different models of equipments are combined to meet different customers' demands according to different craft requirements.

Process of stone crushing & screening plant

1. Big rocks are transported to the working site of stone production plant from quarry.

2. The rocks are transferred to primary crusher by vibrating feeder. Once there is a hopper prior to the vibrating feeder, the rocks are stored in the hopper firstly.

3. The crushed materials are transferred to Impact Crusher by Belt Conveyor for secondary crushing.

4. The materials are transferred to the vibrating screen, and screened into different sizes.

5. Those aggregate with suitable size will be transferred to the final product pile; while those with unsuitable size will be transferred to the Impact Crusher for re-crushing.

This forms a closed circuit manifold cycles. The sizes of final products will be graded and separated according to customers' requirements and application, and the deduster will be attached for the sake of environment protection.

Main advantages of stone crushing & screening plant

1. Customerized design

The production line is designed according to customer's requirement on the output size, types of output and capacity, as well as other factors such as material property, site conditions and purpose.

2. High efficiency and low cost

The arrangement of the machines in the production line can work efficiently and act for the maximum effect, which can ensure the efficiency and increase the output in unit time so that to lower the average cost of finished product (per ton).

3. Standard component

It is much convenien for replacement and maintenance of the machines. Shorten the shutdown time resulted from those maintenance.

4. Optimized production flow

The optimized production flow can ensure the capacity of the whole production line, the density of piling up and the shape of finished product, to satisfy the various purpose of product.

- Q: I just got my first period. It's not heavy, but not light either. i sleep 10-12 hours a night, so i can't use a tampon, and i've slept nude my whole life so i can't wear underwear and a pad. What can I do?

- I guess it's an useful gift, if you had 2 fires It's not going to be anything someone would say OH MY GOD I GOT A FIRE EXTINGUISHER THANK YOU THANK YOU, but yeah, at least it may have it's uses. Though, if those fires were because of someone, be careful as to not make this gift looks like an insult to that person.

- Q: I want to find a Chinese manufacturer of machine like metallurgical equipment, ball mill, crusher, vibrating screen, conveyor, dryer, magnetic separator, who can give me some advice?

- I okorder /

- Q: I have a whirlpool fridge with an ice maker that can crush ice. The crushed ice is good but I want them to be smaller, like Tijuana Flats or Sonic Burger. Can I upgrade my ice crusher?

- You can't really upgrade the ice crusher in your refrigerator. Try getting an inexpensive blender that you can place the crushed ice in to make it smaller.

- Q: im having my baby shower this weekend and i was wondering if anyone has any ideas for what the guys can do at the shower other than sit there and be bored.. i want them to have a good time and i know men don't usually attend showers so if anyone has any ideas PLEASE let me know Thanx!-Miz Gholson

- Rock crushers require some specialized parts, such as the cone or rollers, which are NOT easily made by a DIYer. I suggest you try to buy the size rock you need locally.

- Q: I can't find one anywhere. Manual mean that you manually crush the ice yourself. It looks like this:

- Faced with the same problem, I looked on line and found several available; but then I read some of the comments posted and decided that the ones for sale now are not as durable and reliable as they were 40 years ago. I solved the problem by finding an old one at the flea market for $ 2 which I ran through my dishwasher to sanitize it. I used it today to crush ice for Irish Cream. Works just fine.

- Q: When plastic film is broken, how can the film paper not be copied and swallowed? What's the principle? 60 crusher

- Terms of settlement1, reduce the speed, when the mill does not produce wind prevail2. The plastic film is kneaded into a ball and then into the crusher3. Change pulverizer equipment

- Q: a lock on it? I need it for my daycare but can't locate one...any ideas?

- My guess would be to look at Walgreens, CVS or some other major pharmaceutical store or ask your local pharmacy. If you still have no luck, my last thought would be to look online, surely you would find one that way. GOOD LUCK!

- Q: How do I access myspace from a blockedd school computer that is really really blocked

- Any thing that Obscures the license plate numbers is illegal in all states. Because the state of Tennessee relies so heavily on speed camera's and some covers that are clear are designed to block the ability of such camera's to record the license plate number, yes.

- Q: ahahaha... that actually made me laugh. ... then again im high.

- And you can laugh a spineless laugh. We hope your rules and wisdom choke you.

- Q: i am absolutely shocked and crying and i just cant believe was happened. i am a young single mother of two and i was working a job that i was getting a GOOD salary higher then other places. i didnt like it THAT much but i was glad to be able to put food on the table for once. anyway a week ago was payday i went to pick up my check. then i cashed it. well i found out the check BOUNCED. and a few hours ago i called my boss to ask him what to do. he SCREAMED at me and called me a BITСН and then he fired me on the spot and HUNG UP he said if i came back he WOULD CALL THE COPS. sorry for the caps but i am just going crazy. anyway i need answers, i need to know what i can do, should i try to get my job back or just sue them for all the stress and money theyve caused me. i am just WOW - i am crying my eyes out. i am just in shock its upsetting the kids :(

- yes, me and my friend got kicked out cuase she was throwing gummy worms at the screen and they were sticking and then she was cussing so bye bye us :( and i got kicked out of a hotel cause my friend (different friend) was making popcorn and forgot so it over heated and cuaght fire so all the smoke detectors went off and we put out the fire but they asked us to never come within a mile of their hotel oh and out of a romatic resterant cause i couldnt stop laughing and being noisy (i dont even know what i was laughing about)

Send your message to us

high efficiency jaw crusher used for mining PE 150*250

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches