high efficiency jaw crusher used for mineral PE 600*750

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Jaw stone crusher machine:

1.ISO9001:2000

2.Price:negotiable

3.Capacity:5-800T/H

4.Payment terms:L/C or T/T

Jaw stone crusher machine:

1.ISO9001:2000

2.Price:negotiable

3.Capacity:5-800T/H

4.Payment terms:L/C or T/T

Jaw Crusher Description

The jaw crusher we offers are ideal for primary and secondary crushing. Jaw Crusher is one of the main types of primary crushers in a mine or ore crushing process plant and also is one of the most widely used crushing equipments in mining industry.We are famous jaw crusher manufacturers in China, and sold crusher machines to all over the world. This series of jaw crusher can reach the crushing ratio of 4-6 and the shape of final product is even. Because it is primary crusher, Jaw crusher is designed for long life service with minimum maintenance for hard, tough, abrasive material and overload high capacity

Jaw Crusher Working Principle

Primary jaw crusher is typically of the square opening design, and secondary jaw crusher is of the rectangular opening design. Jaw Crusher reduces large size rocks or ore by placing the rock into compression. A fixed jaw board, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the stationary plate. The space at the bottom of the "V" aligned jaw plates decide the crusher product size gap, or the size of the crushed product from the jaw crusher. The rock remains in the jaw until it is small enough to pass through the gap at the bottom of the jaws.

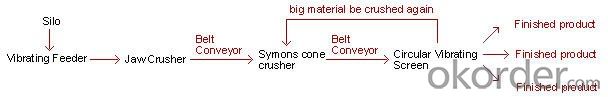

Brief introduction to stone crushing & screening plant

we manufactures various equipments for whole set of stone production line, and provide complete technical support for customers. The whole production line consists of Vibrating Feeder, Jaw Crusher, Impact Crusher, vibrating screen, Belt Conveyor, electric control cabinet and etc.

We design different production lines ranging 50 t/h to 500 t/h by combining different models of equipments.It is widely used for crushing hard limestone, granite, basalt, gravel, metallurgic slag, etc or artificial sand making for hydroelectric power, building material, high way, city construction, etc. Different models of equipments are combined to meet different customers' demands according to different craft requirements.

Process of stone crushing & screening plant

1. Big rocks are transported to the working site of stone production plant from quarry.

2. The rocks are transferred to primary crusher by vibrating feeder. Once there is a hopper prior to the vibrating feeder, the rocks are stored in the hopper firstly.

3. The crushed materials are transferred to Impact Crusher by Belt Conveyor for secondary crushing.

4. The materials are transferred to the vibrating screen, and screened into different sizes.

5. Those aggregate with suitable size will be transferred to the final product pile; while those with unsuitable size will be transferred to the Impact Crusher for re-crushing.

This forms a closed circuit manifold cycles. The sizes of final products will be graded and separated according to customers' requirements and application, and the deduster will be attached for the sake of environment protection.

Main advantages of stone crushing & screening plant

1. Customerized design

The production line is designed according to customer's requirement on the output size, types of output and capacity, as well as other factors such as material property, site conditions and purpose.

2. High efficiency and low cost

The arrangement of the machines in the production line can work efficiently and act for the maximum effect, which can ensure the efficiency and increase the output in unit time so that to lower the average cost of finished product (per ton).

3. Standard component

It is much convenien for replacement and maintenance of the machines. Shorten the shutdown time resulted from those maintenance.

4. Optimized production flow

The optimized production flow can ensure the capacity of the whole production line, the density of piling up and the shape of finished product, to satisfy the various purpose of product.

- Q: Is a single jaw crusher easy to use?

- Greatly simplify the crushing production line, the provincial investment (omitted two, three grade crusher and conveyor), the province covers an area, energy saving and consumption reduction, and easy to manage. Not only has promoted the technical progress of "crusher", but also promoted the technological progress of "broken production line".

- Q: When you do skull crushers are your elbows supposed to hurt afterwards?

- That's the problem with tricep isolation exercises. They can be tough on the elbow joint. Some folks can tolerate them without any apparent trouble, but not everyone and you don't want to mess up your elbows. I've never had trouble with the lying tricep press (skullcrusher)but tricep pushdowns are murder on my elbows. I suggest you experiment with other tricep moves. Dips are great. If seated or standing overhead tricep presses also cause you discomfort, try using one solid dumbbell held with both hands and let your elbows point out to the sides instead of forward. Close grip bench presses are another good tricep movement. Protect your elbows. You'll need them for a long time.

- Q: Which one? Also where is the best place to get one?

- NEITHER. If REAL quality is an issue, you should stick to REPUTABLE brands only such as BW, Sennheiser (most affordable), Shure, Grado, Denon, AKG, Audio-Technica (NOT to be mixed with Technic which is utter rubbish as well!), Etymotic or Beyerdynamic. Things like V-Moda, Klipsch, Sony, Panasonic, JVC and Philips are ONLY okay-ish indeed. Please do NOT fall a victim to FASHION ACCESSORIES by buying Boombox, Ministry of Sound, Sol/Republic/Revolution, Noontec Zoro's, Benetton, a-jays, iFrogz, Marley, Fanny Wang, Razer, Karl Kani, WESC, Turtle, JH, Dr.Dre/Beats/Solo, Ludacris/Soul, Koss, Skullcandy, Lady GaGa, Skullcrushers, Monsters nor Bose, because they are ALL seriously overhyped and overpriced fashion blingbling gimmicks with a very poor durability and sound quality, NOTHING else (and those who try to claim they are good do NOT know ANYTHING about QUALITY anyway!), BE THEM FAKE OR NOT! Also, please do NOT focus on the thumping bass that just distorts everything else, instead go for GOOD audio quality IN GENERAL.

- Q: Every single day I come to class this kid sits next to me and he smells like weed badly. I'm getting annoyed because I can't move anywhere without him following me. He thinks sitting next to me will get him closer to his ex gf who i am dating. (a year now, they've been broken up for 3 years) All he does in class is play with his weed crusher and container and when he opens the dang thing it smells horrible, i even come out of class smelling like i just smoked a joint myself. There are three desk in my row, i sit on the end and he sits right beside me in the middle an I don't know how to tell him to move without him beating the crap out of me.

- Ask someone else to sit next to you or sit in the middle of the three desks so he can't be by you.

- Q: Okay so I messaged my crush, Westley on facebook, that I don't know AT ALL. So i ask him if he goes to my school, blah blah blah and all that stuff. So far his reaction is positive, What do I do?

- You don't know him at all... why is he your cruch? Get to know him. Ask him questions about himself. Tell him about yourself.

- Q: why is that part of the book important to scouts character development? i think it is because she learns that not all people are bad. Why is this a significant event to have included in the movie

- They are nice for certain applications, I use them for temporary fixes exclusively them replace them with permanent fittings. If you dont want to solder then I would use compression fittings instead of sharkbite.

- Q: I'm currently making a light-weight quot;battering ramquot; for airsofting in an urban environment. I'd like to give it a catchy nickname. It could be a cool serious nickname or a comedic one, either way works with me im just looking for opinions and ideas. Thanks!

- Tiny...Crusher 2.0....The Toothpick....The salesman....

- Q: Hi, I'm looking to lower the car, but I don't want it so low that my car scrapes the ground. I use my mustang as a daily driver and I'm not sure if the sportlines wouldn't be too low. Will my car scrape on speed bumps? I don't really have any potholes in my area so that shouldn't be a problem. I want my car to be as low as possible without making it a pain to drive and having the car scraping all the time.Thanks,Phillip

- The ultimate weapon, an upgrade from nukes, I guess. Mabey to fight space invaders, or protect us from planet killer asteroids.

- Q: I have a high metabolism. THE WORKOUT: 3 Day Split Monday: Chest/Tricep Day ???x5x5 Flat Bench ???x5x5 Shoulder Press ???x5x5 Skull Crusher Wednesday: Leg Day ???x5x5 Squats ???x5x5 Dead Lift ???x5x5 Calf Raises Friday: Back/Bicep Day 5xFailure Chin Ups 5x5 Barbell Row 5x5 DB Bicep CurlsThose include compound movements which burn fat, but do I need to do any cardio? If so on what days? When do I work abs? Is this a good workout routine for muscle to stay lean and rippped?

- Yes. Do some cardio. You only burn your own muscles if your diet is insufficient. Your abs are not different then most muscle groups and benefit from being stressed and then rested (every other day or every third day). Staying lean is one thing. Looking ripped is another. I went through a lot of deprivation (diet and water) to get to a show appearance, but I would never suggest trying to maintain a constant ripped appearance.

- Q: Patrol Fire Extinguisher Mfg. Co. 325 SO. Desplaines St. Chicago. Ill. U.S.A.There is plenty more writing on the extinguisher, but most of it consists of directions. Hopefully someone recognizes this extinguisher and can share some of the information about it, like its price if I were to sell.Hopefully I have this under the right category, let me know if you have suggestions for another category I could post under.Thanks in advance, please let me know if you want me to share the rest of the writing on it.

- Triceps extensions and skull crushers. For skull crushers lay on a bench or floor and hold your dumbbells above you and extend them back toward your ears. For triceps extensions, put one knee on a bench and your opposite hand on the bench two feet in front of you. Bend over and hold the dumbbell to your side. Extend it straight back behind you and then back to its resting position. For pictures Google triceps extensions, it gives you both skull crushers and triceps extensions.

Send your message to us

high efficiency jaw crusher used for mineral PE 600*750

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches