High Alumina Ceramic Fiber Board for Cement Kilns Refractory Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

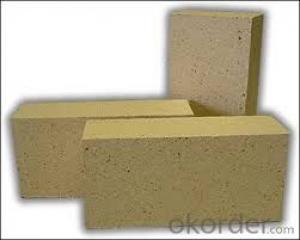

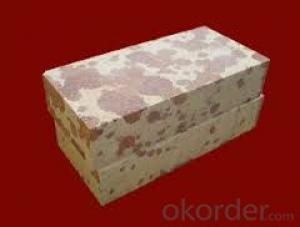

Description of Refractory Bricks for Cement Kilns High Alumina

Refractory Bricks for Cement Kilns High Alumina is made of high grade bauxite through high temperature calcinations. The Al2O3 content is usually above 48% . High alumina brick is a kind of neutral refractory material so that it enjoys excellent resistance to acid and alkali corrosion.

Feature of Refractory Bricks for Cement Kilns High Alumina

1. High-temperature endurable .

2.Good thermal shock resistance.

3.High cold crushing strength

4.Good resistance to abrasion and corrosion.

5.Good thermal spalling resistance.

6.High mechanical strength.

7.Good volume stability at high temperature.

Application of Refractory Bricks for Cement Kilns:

Refractory Bricks for Cement Kilns is used for building blast furnaces, hot blast stove, electric stove roof, ladle,blast furnace and reverberatory furnace, lining of rotary kiln and glass kiln and chemical industrial kiln. In addition, high alumina brick is widely used as regenerative checker brick of open hearth, pouring system with the plug head, nozzle brick, etc.

Data of Refractory Bricks for Cement Kilns

| Item | SK38 | SK37 | SK36 | SK35 |

| Al2O3 % | ≥75 | ≥65 | ≥55 | ≥48 |

| Fe2O3 % | ≤2 | ≤2 | ≤2 | ≤2 |

| Refractoriness °C | ≥1790 | ≥1770 | ≥1750 | ≥1420 |

| Apparent porosity % | ≤23 | ≤23 | ≤22 | ≤22 |

| Cold crushing strength Mpa | ≥53.9 | ≥49.0 | ≥44.1 | ≥39.2 |

| Refractoriness under load(0.2MPa) °C | ≥1520 | ≥1500 | ≥1470 | ≥1420 |

| Reheating Linear Change % | +0.1(1500°C, 2h) | -- | ||

| +0.1(1500°C, 2h) | -- | |||

- Q: What method should be used to measure the thermal conductivity of fiberboard?

- Fiber board thermal conductivity of ceramic fiber board thermal conductivity information is mainly: ceramic fiber board thermal conductivity, thermal conductivity of ceramic fiber board price, thermal conductivity of ceramic fiber board wholesale, thermal conductivity of ceramic fiber board factory, discusses the protection method of hot plate test principle and method of MDF thermal conductivity and its relation with temperature; and analyzed the test error.

- Q: What are the standards for ceramic fiber boards?

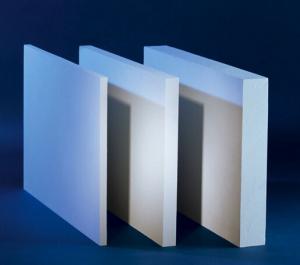

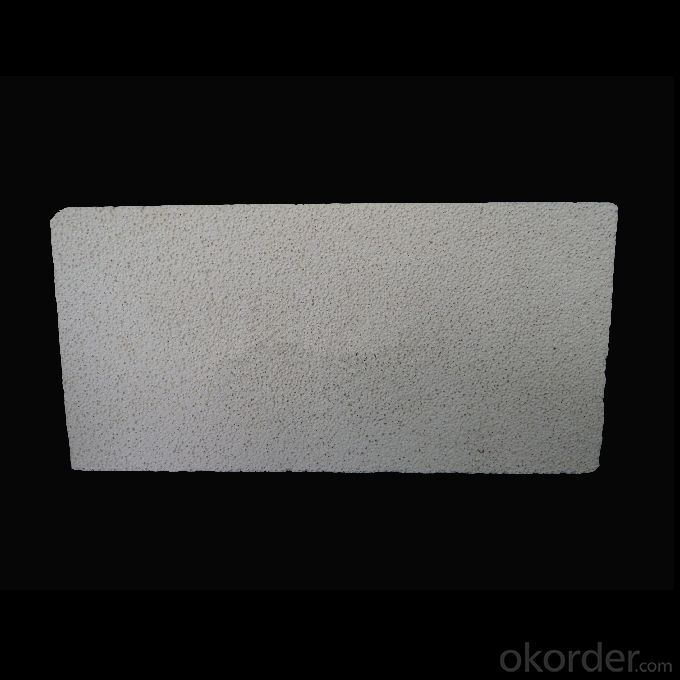

- Ceramic fiber board is made of continuous production, water production line and advanced technology, ceramic fiber board produced with smooth surface, accurate size, good toughness, can be arbitrarily cut, good insulation effect and other performance characteristics.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Volume density is low: the density of the ceramic fiber lining is about 25% of the lining of the light heat insulation brick, about 10% of the lining of the light pouring material; adopting the fiber lining can greatly reduce the steel structure load of the furnace and prolong the service life of the furnace lining.

- Q: Refractory insulation board, pressure plate, nano heat transfer plate, calcium silicate board and ceramic fiber board, which is good?

- Sheng Yang series of ceramic fiber board is based on the traditional process of comprehensive upgrading of the excellent vacuum forming insulation materials, slag ball content of less than 3%, fiber distribution uniformity, internal and external strength consistent, size controllable.Ceramic fiber board is made by spraying superfine ceramic fiber through water washing, slag removal, fiber freezing and vacuum forming. The product has superior high temperature resistance, excellent rigidity and toughness.

- Q: What are the sound-absorbing fiber boards?

- Ordinary materials have sound-absorbing effect, just how much difference. And when it comes to sound-absorbing board, we are only sound-absorbing coefficient of more than 0.3 of the material known as sound-absorbing material.

- Q: What is the difference between ceramic fiber board and nano ceramic fiber board?

- The nano ceramic fiber board through the introduction of nanotechnology, the special production process, product performance has been greatly improved, high strength, low thermal conductivity, good heat insulation performance, energy saving effect is obvious, which improves the safety of the furnace, and in high temperature and high pressure conditions, can also play a good performance the product.

- Q: What are the specifications of the ceramic fiber board?

- Ceramic fiber board, also known as aluminum silicate or refractory fiber, including ceramic fiber blanket, ceramic fiber, ceramic fiber fireproof plate (plate).

- Q: What are the differences between nano ceramic plate and ceramic fiber board?

- Nano ceramic plate for ceramic fiber with insulating board (felt), it is a functional material with excellent properties of aerogel insulation material and has a heat shielding function, adaptation to adhesive and a variety of inorganic elements in high temperature ceramic fiber as reinforcing material, through a special process preparation.

- Q: Is there any difference between ceramic silicon fiber board and ceramic fiber board?

- Ceramic fiber board is aluminum silicate fiber board, a refractory material. Even after heating, good mechanical strength is maintained. The product is a fibrous insulation product that is rigid and has a supporting strength compared to fiber blankets. Features: ceramic fiber board has excellent quality, toughness and strength, besides, it has excellent resistance to wind erosion. The utility model has the advantages of no heat expansion, light weight, convenient construction, and arbitrary shearing and bending. The utility model is an ideal energy-saving material for kilns, pipes and other heat preservation equipment.

- Q: How much pressure can the ceramic fiber board withstand?

- Ceramic fiber fireproof plate, the density of 350-400Kg/m ceramic fiber board, fand; density above fand 400Kg/m.

Send your message to us

High Alumina Ceramic Fiber Board for Cement Kilns Refractory Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords