High Alumina Bricks for Blast Furnace - High Aluminium Fireclay Bricks Supplier

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Aluminium Bricks and Fireflay Bricks Supplier Used in Blast Furnace in China

Brief discription for high aluminium bricks

CMAX high aluminium bricks are classified according to alumina content ranging from 48% to 90%.

CMAX high alumina bricks are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln,regenerator, etc.

Brief features for high aluminium bricks

◆Low thermal conductivity

◆Excellent acid and base slagging resistance

◆High refractoriness

◆Excellent thermal shock resistance

◆Excellent mechanical strength

◆Good spalling resistance and wear resistance.

◆Good corrosion resistance.

◆High-temperature creep rate is low.

◆Good volume stability at high temperature.

◆Low bulk density, low thermal conductivity, good thermal insulation performance.

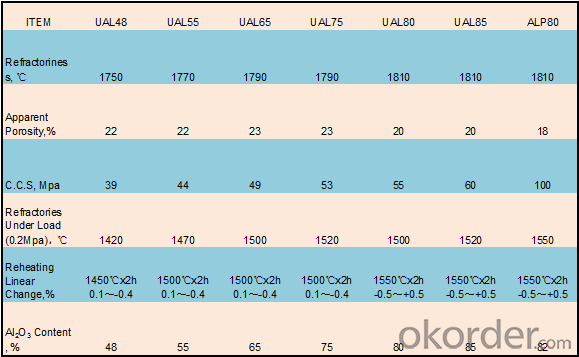

Technical data for high aluminium bricks

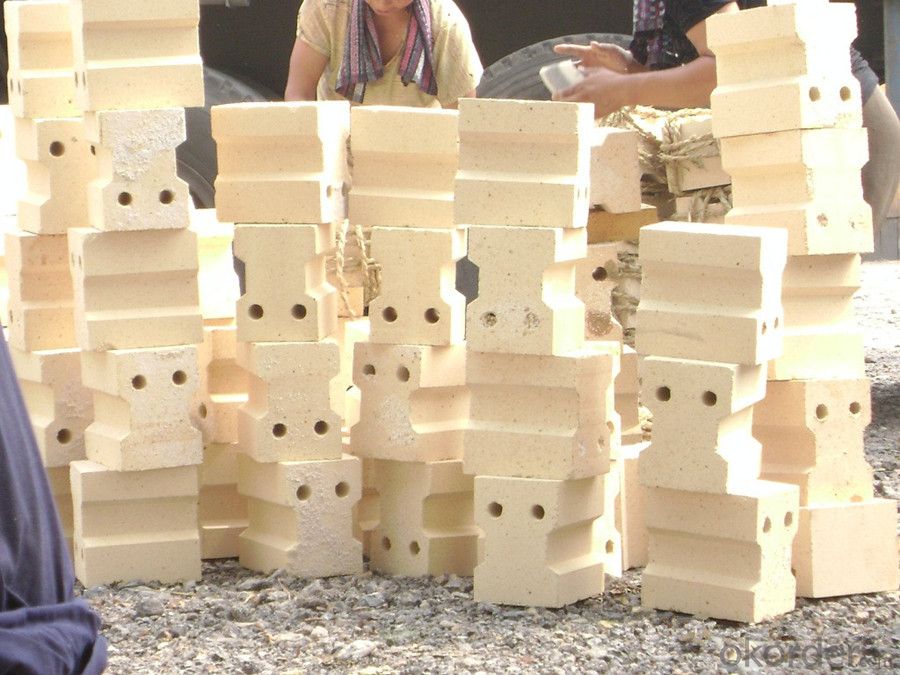

Images/photographs for high aluminium bricks

◆ breif images

◆ Packaging for high aluminium bricks

◆ Producing Equipment for high aluminium bricks

◆ Testing Mashines for high aluminium bricks

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

If you have any enquiry,please don't hesitate to contact us,we will provide our best products and services for you!!

- Q: What is the difference between corundum and high alumina??

- The main components of high alumina brick are high alumina bauxite, mullite and partial corundum sand.

- Q: What are the grades of high alumina bricks?

- According to the size of high aluminum brick is divided into: standard brick, special-shaped brick.

- Q: What are the requirements for Rubble backfill height?

- 1, filling thickness is not greater than 50cm.2, filling, the use of layered filling.

- Q: Density of high alumina bricks

- High alumina brick by aluminum content is divided into four grades, three grade high alumina bricks content of not less than fifty-five percent, two grade high alumina bricks content of not less than 65, a high aluminum brick content of not less than 75, super high aluminium brick content above 85. As for the high aluminum brick shape, in addition to the standard high alumina brick, high alumina brick and general type, also called special high alumina brick, if the shape is very irregular it is usually called the specific type of high alumina brick, in short, to customized according to the specific use of kiln.

- Q: What are the common thermal insulation materials for thermal conductivity?

- Aerogels are known to be the lightest solid materials in the world. It is made of nanometer silica aerogel as main material and is compounded by special process. The utility model has the advantages of high temperature resistance, low thermal conductivity, small density, high strength, green environment protection, waterproof and non inflammable performance. At the same time, with excellent sound insulation and shock absorption performance, it is now widely used in metallurgy, chemical, national defense, aerospace and other fields, is an indispensable high-performance insulation materials.

- Q: Can high alumina brick resist carburizing?

- The resistance to carburization is not directly related to the bulk density of bricks

- Q: How to reduce porosity of high alumina brick

- In order to reduce the porosity of high alumina brick, the corresponding measures should be taken from the selection of raw materials, batching, mixing, molding and firing.

- Q: What is spalling resistant high alumina brick?

- Using bauxite as main raw materials, the introduction of a small amount of ZrO2 (ZrO2 is due to phase transition, between monoclinic and tetragonal type can improve the thermal stability of the products), adding a certain amount of binder and additives, the particle size distribution control mud, forming and sintering of refractory products produced, called anti stripping high alumina brick.

- Q: What's the weight of the refractory bricks?

- Referred to as refractory brick. Refractory made from refractory clay or other refractory material. Light yellow or brownish. The utility model is mainly used for laying smelting furnaces, and can withstand high temperature between 1580 DEG C and 1770 DEG C. Also called brick. Refractory material of a certain shape and size. According to the preparation process can be divided into bricks, brick, electric melting brick, refractory insulating bricks (Rong Zhuzhuan);

- Q: What is the difference between high alumina brick and clay brick?

- Lightweight high alumina bricks are usually made of high alumina bauxite clinker with a small amount of clay. After grinding, the bricks are poured and shaped in the form of slurry by gas or foam method. They are fired at 1300~1500 DEG C. Sometimes industrial alumina can be used instead of some bauxite clinker. Used for lining and insulation of masonry kilns, as well as for areas where there is no strong, high temperature molten material erosion and erosion. When contacting the flame directly, the surface contact temperature shall not be higher than 1350 degrees centigrade.

Send your message to us

High Alumina Bricks for Blast Furnace - High Aluminium Fireclay Bricks Supplier

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords